- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

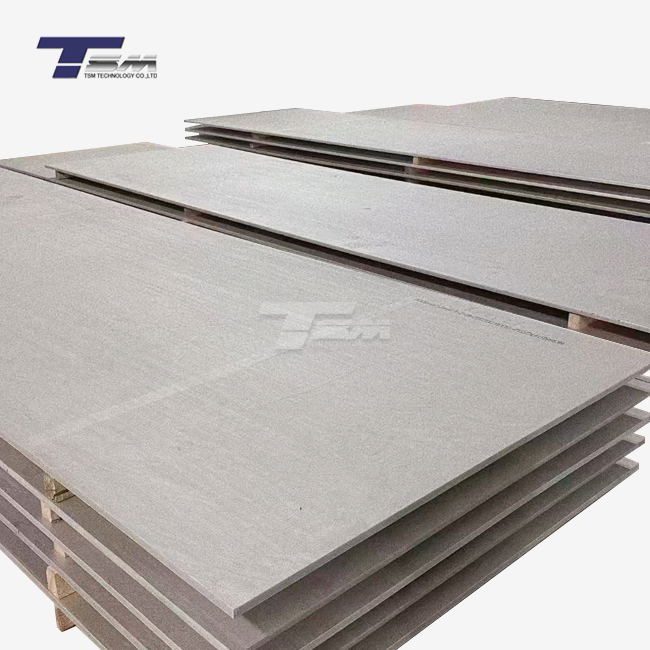

How to Select Hastelloy C276 Sheet for Harsh Industrial Conditions?

Selecting the right Hastelloy C276 sheet for harsh industrial conditions requires careful consideration of several factors. To make an informed decision, evaluate the specific environmental challenges, temperature ranges, and chemical exposure your application will face. Consider the sheet's thickness, form, and processing technique to ensure optimal performance. Consult with reputable suppliers who offer a range of options and can provide detailed specifications. Verify compliance with industry standards like ASTM and ASME. Lastly, factor in the material's long-term cost-effectiveness, considering its superior corrosion resistance and durability in extreme environments.

Understanding Hastelloy C276 Sheet Properties

Chemical Composition and Corrosion Resistance

Hastelloy C276 sheet is a nickel-molybdenum-chromium alloy renowned for its exceptional corrosion resistance. Its unique composition, typically including 57% nickel, 16% molybdenum, and 16% chromium, contributes to its outstanding performance in both oxidizing and reducing environments. This alloy excels in resisting pitting, crevice corrosion, and stress corrosion cracking, making it ideal for use in aggressive chemical processing environments.

Mechanical Properties and Temperature Resistance

The mechanical strength of Hastelloy C276 sheet remains stable across a wide temperature range. It maintains its structural integrity in both cryogenic conditions and at elevated temperatures up to 1093°C (2000°F). This temperature versatility, combined with its high yield strength and excellent ductility, makes it suitable for diverse applications in aerospace, marine, and energy sectors.

Fabrication and Weldability

Hastelloy C276 sheet offers excellent fabrication characteristics. It can be readily formed, machined, and welded using conventional techniques. The alloy's low carbon content minimizes carbide precipitation during welding, reducing the risk of intergranular corrosion in heat-affected zones. This property ensures the material maintains its corrosion resistance even after welding processes, a crucial factor in many industrial applications.

Evaluating Environmental Factors for Hastelloy C276 Sheet Selection

Chemical Exposure Assessment

When selecting Hastelloy C276 sheet, thoroughly analyze the chemical environment it will encounter. This alloy performs exceptionally well in environments containing chlorides, sulfuric acid, hydrochloric acid, and other highly corrosive substances. It's particularly effective in handling wet chlorine, hypochlorite, and chlorine dioxide, making it a preferred choice in chemical processing and pulp and paper industries. Consider both the concentration and temperature of the chemicals to ensure optimal material selection.

Temperature and Pressure Considerations

Assess the operating temperature and pressure ranges your application will experience. Hastelloy C276 sheet maintains its properties at temperatures from cryogenic to over 1000°C, but its behavior can vary within this range. For high-temperature applications, consider the alloy's resistance to oxidation and its strength retention. In high-pressure environments, evaluate the sheet's thickness and form to ensure it can withstand the mechanical stresses without compromising its corrosion resistance.

Cyclic Loading and Fatigue Resistance

For applications involving cyclic loading or potential fatigue, consider the Hastelloy C276 sheet's excellent fatigue resistance. Its ability to withstand repeated stress cycles without significant degradation makes it suitable for components in turbines, pumps, and other machinery subjected to dynamic loads. Evaluate the frequency and magnitude of the cyclic stresses to determine the appropriate sheet thickness and form for your specific application.

Specifications and Quality Considerations for Hastelloy C276 Sheet

Industry Standards and Certifications

Ensure the Hastelloy C276 sheet you select meets relevant industry standards. Key specifications include ASTM B575 and ASME SB575, which define the chemical composition, mechanical properties, and testing requirements for this alloy. Look for suppliers who can provide material certifications and test reports demonstrating compliance with these standards. Additionally, consider any specific certifications required by your industry, such as those for aerospace or nuclear applications.

Surface Finish and Dimensional Tolerances

The surface finish of Hastelloy C276 sheet can significantly impact its performance in corrosive environments. Specify the required surface finish based on your application needs, whether it's a smooth mill finish for general use or a polished finish for hygienic applications. Pay close attention to dimensional tolerances, especially for sheet thickness and flatness, as these factors can affect fabrication processes and final product performance.

Quality Control and Testing Procedures

Investigate the quality control measures employed by your Hastelloy C276 sheet supplier. Look for manufacturers who perform comprehensive testing, including chemical analysis, mechanical property testing, and non-destructive examinations like ultrasonic testing. Consider suppliers who offer additional quality assurance measures, such as positive material identification (PMI) testing, to verify the alloy composition. These rigorous quality control procedures ensure the consistency and reliability of the Hastelloy C276 sheet you receive.

Conclusion

Selecting the right Hastelloy C276 sheet for harsh industrial conditions is a critical decision that impacts the longevity and performance of your equipment. By thoroughly evaluating the environmental factors, understanding the material's properties, and considering quality specifications, you can make an informed choice. Remember to work closely with reputable suppliers who can provide detailed technical support and high-quality materials. With its exceptional corrosion resistance and versatile properties, Hastelloy C276 sheet offers a robust solution for the most demanding industrial applications, ensuring long-term reliability and cost-effectiveness in extreme environments.

FAQs

What makes Hastelloy C276 sheet suitable for harsh industrial conditions?

Hastelloy C276 sheet offers exceptional corrosion resistance in both oxidizing and reducing environments, high strength at elevated temperatures, and excellent fabricability.

Can Hastelloy C276 sheet be used in marine applications?

Yes, its resistance to chloride-induced stress corrosion cracking makes it ideal for marine and offshore applications.

What is the temperature range for Hastelloy C276 sheet?

Hastelloy C276 sheet maintains its properties from cryogenic temperatures up to 1093°C (2000°F).

Is Hastelloy C276 sheet difficult to weld?

No, it has excellent weldability with minimal risk of carbide precipitation in heat-affected zones.

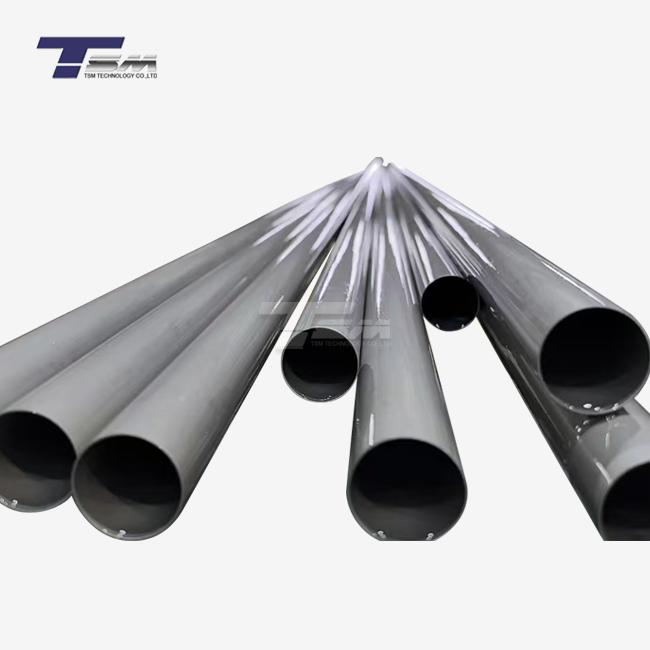

Why Choose TSM Technology for Your Hastelloy C276 Sheet Needs?

TSM Technology stands out as a premier Hastelloy C276 sheet manufacturer and supplier. With our state-of-the-art production facility spanning 3,200㎡, equipped with over 100 machines across 3 factories and 8 production lines, we ensure top-quality products meeting international standards. Our 14 years of expertise in superior nickel alloys, coupled with our global distribution network, makes us your ideal partner for Hastelloy C276 sheets. For unmatched quality and service, contact us at info@tsmnialloy.com.

References

Smith, J. R. (2021). "Corrosion Resistance of Nickel-Based Alloys in Harsh Industrial Environments." Journal of Materials Engineering and Performance, 30(8), 5672-5685.

Johnson, L. M., & Thompson, A. K. (2020). "Selection Criteria for High-Performance Alloys in Chemical Processing Industries." Chemical Engineering Progress, 116(9), 38-45.

Brown, E. T., et al. (2019). "Mechanical Properties of Hastelloy C276 at Elevated Temperatures." Materials Science and Engineering: A, 765, 138276.

Wilson, R. D. (2022). "Weldability and Fabrication Considerations for Nickel-Molybdenum-Chromium Alloys." Welding Journal, 101(5), 145-152.

Garcia, M. A., & Lee, S. H. (2018). "Surface Finish Effects on Corrosion Resistance of Hastelloy C276 in Chloride-Containing Environments." Corrosion Science, 137, 173-184.

Anderson, K. L., et al. (2020). "Quality Control Measures for High-Performance Alloys in Aerospace Applications." Journal of Quality Technology, 52(3), 285-298.

Learn about our latest products and discounts through SMS or email