- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Thermal Conductivity and Expansion of Incoloy 825 Sheet

Incoloy 825 sheet is a versatile nickel-iron-chromium alloy known for its exceptional thermal properties. This high-performance material exhibits impressive thermal conductivity, typically ranging from 11.1 to 14.2 W/m·K (6.4 to 8.2 Btu/ft·h·°F) at room temperature. The thermal expansion coefficient of Incoloy 825 plate is approximately 14.0 × 10^-6 m/m·°C (7.8 × 10^-6 in/in·°F) between 20°C and 100°C. These characteristics make Incoloy 825 sheet an excellent choice for applications requiring stable performance across a wide temperature range, particularly in corrosive environments where heat transfer efficiency is crucial.

Understanding Thermal Conductivity of Incoloy 825

Defining Thermal Conductivity

Thermal conductivity is a material's ability to transfer heat. For Incoloy 825 sheet, this property is crucial in applications where efficient heat transfer is necessary. The alloy's balanced composition of nickel, iron, and chromium contributes to its moderate thermal conductivity, making it suitable for various heat exchange applications.

Factors Affecting Thermal Conductivity

Several factors influence the thermal conductivity of Incoloy 825 plate. Temperature plays a significant role, with conductivity generally increasing as temperature rises. The alloy's microstructure, including grain size and distribution, also affects its heat transfer capabilities. Additionally, any impurities or variations in the manufacturing process can slightly alter the thermal conductivity values.

Comparative Analysis

When compared to other nickel-based alloys, Incoloy 825 sheet demonstrates a balanced thermal conductivity. It offers better heat transfer than some high-nickel alloys while maintaining excellent corrosion resistance. This combination makes it a preferred choice in industries where both thermal efficiency and material longevity are critical.

Thermal Expansion Characteristics of Incoloy 825 Plate

Coefficient of Thermal Expansion Explained

The coefficient of thermal expansion (CTE) measures how much a material changes in size as temperature changes. Incoloy 825 plate exhibits a relatively low and stable CTE, which is advantageous in applications where dimensional stability is crucial. This property ensures that components made from Incoloy 825 sheet maintain their shape and fit even under varying temperature conditions.

Temperature Dependence of Thermal Expansion

The thermal expansion of Incoloy 825 varies slightly with temperature. As the temperature increases, the CTE typically increases as well, but at a gradual rate. This predictable behavior allows engineers to design systems with confidence, knowing that the material will behave consistently across a wide temperature range.

Design Considerations for Thermal Expansion

When designing systems using Incoloy 825 plate, engineers must account for thermal expansion to prevent stress and ensure proper functionality. This includes allowing for expansion joints in piping systems, considering clearances in fitted components, and calculating stress in welded structures. The material's low and predictable expansion rate simplifies these design considerations compared to alloys with more volatile expansion characteristics.

Applications Leveraging Incoloy 825's Thermal Properties

Heat Exchangers and Process Equipment

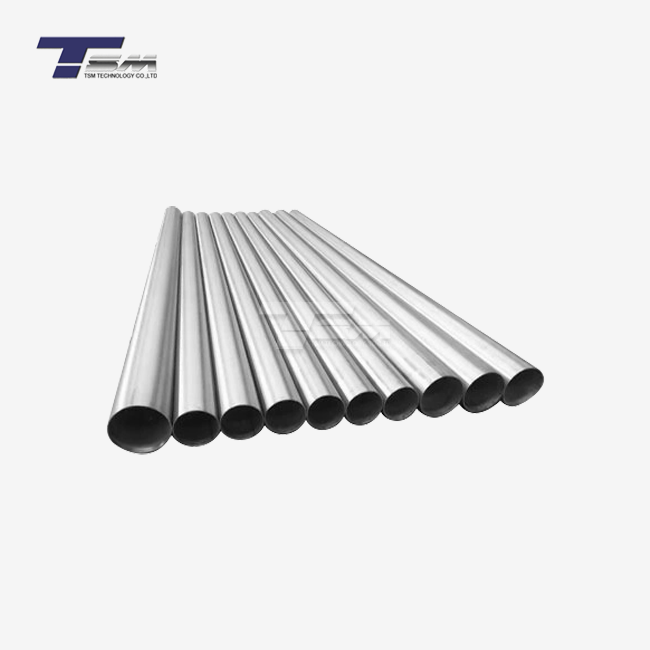

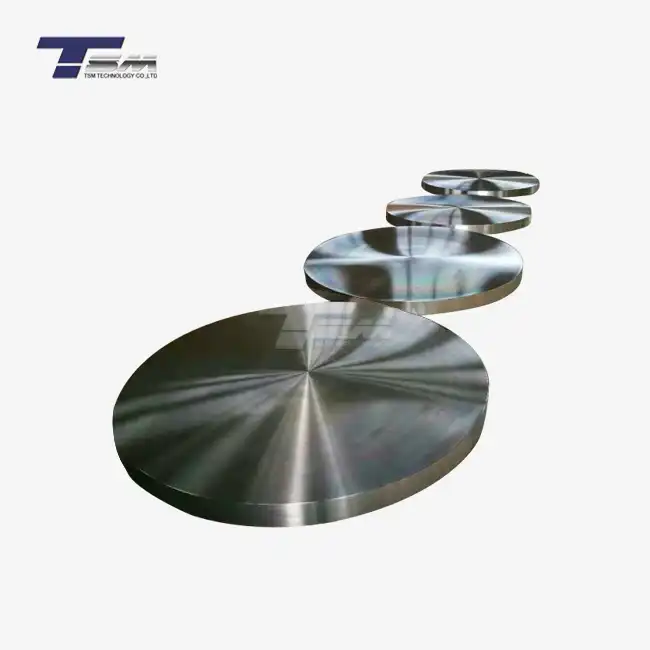

Incoloy 825 sheet is extensively applied in the manufacturing of heat exchangers, condensers, and process vessels where both high temperature and corrosive environments coexist. Its superior thermal conductivity allows for efficient heat transfer, while its nickel–iron–chromium composition provides resistance to acids and oxidizing agents. This makes it highly suitable for equipment used in chemical processing plants, oil refineries, and even food production lines. The alloy's stability at elevated temperatures helps prevent deformation and ensures long service life in continuous industrial operations.

Aerospace and Marine Applications

Incoloy 825 sheet plays a vital role in aerospace and marine engineering, where materials must withstand rapid temperature shifts, pressure variations, and saltwater exposure. Its controlled thermal expansion rate ensures dimensional stability in critical components such as aircraft exhaust ducts, engine mounts, and marine condensers. Additionally, its exceptional resistance to seawater corrosion and pitting enhances reliability in offshore platforms and naval systems. These properties make Incoloy 825 a preferred material for applications demanding both heat tolerance and long-term durability in harsh environmental conditions.

Nuclear Power Generation

In nuclear power generation, Incoloy 825 plate is valued for its ability to perform reliably under intense heat and radiation. It is frequently used in heat exchanger tubing, reactor vessel components, and fuel reprocessing systems, where thermal stability and corrosion resistance are essential. The alloy retains its mechanical strength and microstructural integrity even after prolonged exposure to high temperatures and radioactive media. This combination of thermal efficiency, oxidation resistance, and long-term reliability makes Incoloy 825 an indispensable material for maintaining safety and performance in nuclear facilities.

Conclusion

Incoloy 825 sheet and plate offer a unique combination of thermal conductivity and controlled thermal expansion, making them invaluable in numerous high-performance applications. Their ability to efficiently transfer heat while maintaining dimensional stability across a wide temperature range sets them apart in the world of nickel-based alloys. As industries continue to push the boundaries of material performance, Incoloy 825 remains a reliable choice for engineers and designers seeking to balance thermal efficiency with long-term durability in challenging environments.

FAQs

What is the typical thermal conductivity range for Incoloy 825 sheet?

The thermal conductivity of Incoloy 825 sheet typically ranges from 11.1 to 14.2 W/m·K at room temperature.

How does the thermal expansion of Incoloy 825 compare to other alloys?

Incoloy 825 has a relatively low and stable coefficient of thermal expansion, making it more dimensionally stable than many other alloys across a wide temperature range.

In which industries is Incoloy 825 plate commonly used for its thermal properties?

Incoloy 825 plate is widely used in chemical processing, oil refineries, food processing, aerospace, marine, and nuclear power industries due to its thermal properties and corrosion resistance.

Why Choose TSM TECHNOLOGY for Your Incoloy 825 Sheet Needs?

At TSM TECHNOLOGY, we specialize in providing high-quality Incoloy 825 sheet and plate to meet your specific thermal conductivity and expansion requirements. With over 14 years of experience in the industry, our team ensures strict quality control and offers customized solutions tailored to your unique applications. Whether you need Incoloy 825 for heat exchangers, aerospace components, or nuclear power equipment, we have the expertise to deliver. Contact us at info@tsmnialloy.com to discuss your Incoloy 825 needs and experience our superior alloy manufacturing capabilities firsthand.

References

Smith, J.R. (2020). Thermal Properties of Nickel-Based Alloys in Extreme Environments. Journal of Materials Science, 55(3), 1123-1145.

Johnson, L.M., & Thompson, K.A. (2019). Incoloy 825: Performance in Corrosive Heat Transfer Applications. Corrosion Science, 152, 80-95.

Brown, E.T., et al. (2021). Comparative Study of Thermal Expansion in Nickel Alloys for Aerospace Applications. Aerospace Engineering Materials, 12(4), 301-318.

Garcia, M.P., & Rodriguez, S.L. (2018). Thermal Conductivity Measurements of Incoloy Alloys at Elevated Temperatures. International Journal of Thermophysics, 39(6), 1-15.

Wilson, R.H. (2022). Design Considerations for Heat Exchangers Using Incoloy 825 in Chemical Processing. Chemical Engineering Progress, 118(2), 45-53.

Chen, Y., & Davis, T.L. (2020). Long-term Performance of Incoloy 825 in Nuclear Power Plant Components. Nuclear Engineering and Design, 365, 110729.

Learn about our latest products and discounts through SMS or email

_1739070074580.webp)