Understanding Incoloy 825 Round Bars: Properties and Applications

Composition and Unique Characteristics

Incoloy 825 is a nickel-iron-chromium alloy with added molybdenum, copper, and titanium. This unique composition grants it exceptional resistance to both oxidizing and reducing environments. The alloy's high nickel content provides excellent protection against chloride stress corrosion cracking, while chromium offers resistance to oxidizing acids. Molybdenum enhances its resistance to pitting and crevice corrosion, making Incoloy 825 round bars an ideal choice for harsh chemical environments.

Mechanical Properties

Incoloy 825 round bars exhibit impressive mechanical properties, including high strength and excellent ductility. They maintain their structural integrity across a wide temperature range, from cryogenic to elevated temperatures. The alloy's yield strength typically ranges from 240 to 300 MPa, with a tensile strength of 590 to 690 MPa. These properties ensure reliable performance in demanding chemical processing applications where both strength and corrosion resistance are critical.

Common Applications in Chemical Industries

Incoloy 825 round bars find extensive use in various chemical industry applications due to their superior corrosion resistance and mechanical properties. They are commonly employed in the fabrication of heat exchangers, reaction vessels, and piping systems in chemical processing plants. The alloy's resistance to sulfuric and phosphoric acids makes it particularly suitable for handling pickling solutions and fertilizer production equipment. Additionally, Incoloy 825 round bars are utilized in oil and gas extraction, pollution control systems, and nuclear fuel reprocessing facilities.

Key Factors in Selecting Incoloy 825 Round Bars

Chemical Environment Compatibility

When selecting Incoloy 825 round bars for chemical industries, it's crucial to assess the specific chemical environment they will be exposed to. Consider the types of acids, bases, or other corrosive substances present in your processes. Incoloy 825 excels in environments containing sulfuric, phosphoric, and nitric acids, as well as mixed acid solutions. Its resistance to chloride-induced stress corrosion cracking makes it suitable for applications involving seawater or chloride-containing chemicals. Evaluate the concentration and temperature of the chemicals to ensure the alloy's suitability for your specific application.

Temperature and Pressure Requirements

Incoloy 825 round bars maintain their excellent properties across a wide temperature range, from cryogenic to around 540°C (1000°F). When selecting these bars, consider both the operating and maximum temperatures your equipment will encounter. Additionally, factor in the pressure conditions, as Incoloy 825's high strength allows it to withstand significant pressure loads. For applications involving frequent temperature fluctuations or thermal cycling, Incoloy 825's low coefficient of thermal expansion provides excellent dimensional stability, reducing the risk of fatigue or stress-related failures.

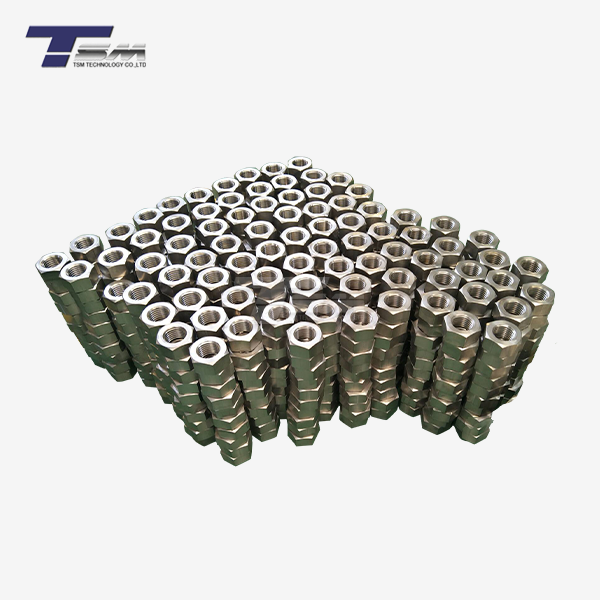

Size and Dimensional Specifications

The dimensions of Incoloy 825 round bars play a crucial role in their selection for chemical industry applications. Consider the required diameter, which can range from 3mm to 400mm, depending on the supplier. Assess the length needed for your specific equipment or component, keeping in mind that longer bars may require additional support to prevent sagging or deformation. Pay attention to tolerances and surface finish requirements, as these can affect the bar's fit, function, and corrosion resistance in your application. Reputable suppliers like TSM Technology offer customization options to meet specific dimensional needs, ensuring optimal performance in your chemical processing equipment.

Ensuring Quality and Compliance in Incoloy 825 Round Bar Selection

Material Certification and Testing

When selecting Incoloy 825 round bars for chemical industries, it's essential to verify the material's certification and testing documentation. Reputable suppliers should provide material test reports (MTRs) that confirm the chemical composition, mechanical properties, and heat treatment history of the bars. Look for certifications that comply with industry standards such as ASTM B425, which outlines the specifications for Incoloy 825 products. Additionally, consider requesting additional testing, such as ultrasonic inspection or dye penetrant testing, to ensure the bars are free from internal defects or surface imperfections that could compromise their performance in corrosive environments.

Manufacturing Process and Quality Control

The manufacturing process of Incoloy 825 round bars significantly influences their quality and performance. Opt for suppliers who employ advanced production techniques, such as vacuum arc remelting (VAR) or electroslag remelting (ESR), which enhance the alloy's cleanliness and homogeneity. Inquire about the supplier's quality control measures, including in-process inspections and final product testing. Suppliers with ISO 9001 certification, like TSM Technology, demonstrate a commitment to consistent quality management. Additionally, consider the supplier's capability to provide specialized treatments, such as solution annealing or pickling, which can further enhance the corrosion resistance of Incoloy 825 round bars for chemical industry applications.

Supplier Reputation and Technical Support

Choosing a reputable supplier is crucial when selecting Incoloy 825 round bars for chemical industries. Look for manufacturers with a proven track record in producing high-performance alloys and serving the chemical sector. Consider factors such as the supplier's years of experience, industry certifications, and customer testimonials. A reliable supplier should offer comprehensive technical support, including assistance with material selection, guidance on fabrication techniques, and advice on optimizing the performance of Incoloy 825 round bars in specific chemical environments. TSM Technology, for instance, combines extensive experience with cutting-edge production facilities to deliver high-quality Incoloy 825 round bars backed by expert technical support.

Conclusion

Selecting the right Incoloy 825 round bars for chemical industries is a critical decision that impacts the safety, efficiency, and longevity of your equipment. By carefully considering factors such as chemical compatibility, temperature and pressure requirements, and dimensional specifications, you can make an informed choice. Prioritize quality assurance through proper material certification, advanced manufacturing processes, and reputable suppliers. Remember that investing in high-quality Incoloy 825 round bars from trusted manufacturers like TSM Technology can lead to improved performance, reduced maintenance costs, and enhanced safety in your chemical processing operations. With the right selection, you can harness the full potential of Incoloy 825's exceptional corrosion resistance and mechanical properties in your demanding chemical industry applications.

FAQs

What makes Incoloy 825 round bars suitable for chemical industries?

Incoloy 825 round bars offer exceptional corrosion resistance in both oxidizing and reducing environments, high strength, and excellent performance across a wide temperature range, making them ideal for chemical processing applications.

What sizes are available for Incoloy 825 round bars?

TSM Technology offers Incoloy 825 round bars in diameters ranging from 3mm to 400mm, with customizable lengths up to 6 meters.

How can I ensure the quality of Incoloy 825 round bars?

Look for suppliers like TSM Technology that provide material certifications, adhere to ASTM B425 standards, and offer comprehensive quality control measures throughout the manufacturing process.

Choose TSM Technology for Premium Incoloy 825 Round Bars

TSM Technology stands as a leading manufacturer of high-quality Incoloy 825 round bars, offering unparalleled expertise and product quality. With our state-of-the-art 3,200㎡ production facility, featuring advanced vacuum arc furnaces and 2,500-ton forging presses, we ensure precision and consistency in every bar. Our ISO 9001 and AS9100 certifications guarantee adherence to the highest quality standards. For superior Incoloy 825 round bars tailored to your chemical industry needs, trust TSM Technology. Contact us at info@tsmnialloy.com for expert guidance and competitive pricing from our factory.

References

ASTM International. (2020). "ASTM B425 - Standard Specification for Ni-Fe-Cr-Mo-Cu Alloy (UNS N08825 and UNS N08221) Rod and Bar"

Special Metals Corporation. (2019). "Incoloy alloy 825 Technical Data Sheet"

Patel, S. J., & Vyas, K. N. (2018). "Nickel and Nickel Alloys for Corrosion Resistance" in ASM Handbook, Volume 13B: Corrosion: Materials

Rebak, R. B., & Crook, P. (2017). "Nickel Alloys for Corrosive Environments" in Advanced Materials & Processes

Davis, J. R. (Ed.). (2016). "Nickel, Cobalt, and Their Alloys" ASM Specialty Handbook

Stein, K. P., & Noecker, F. F. (2015). "Selection and Application of Wrought Nickel Alloys" in ASM Handbook, Volume 22B: Metals Process Simulation