The Importance of Nickel Alloy Round Bars in Aerospace Applications

Enhanced Performance in Extreme Conditions

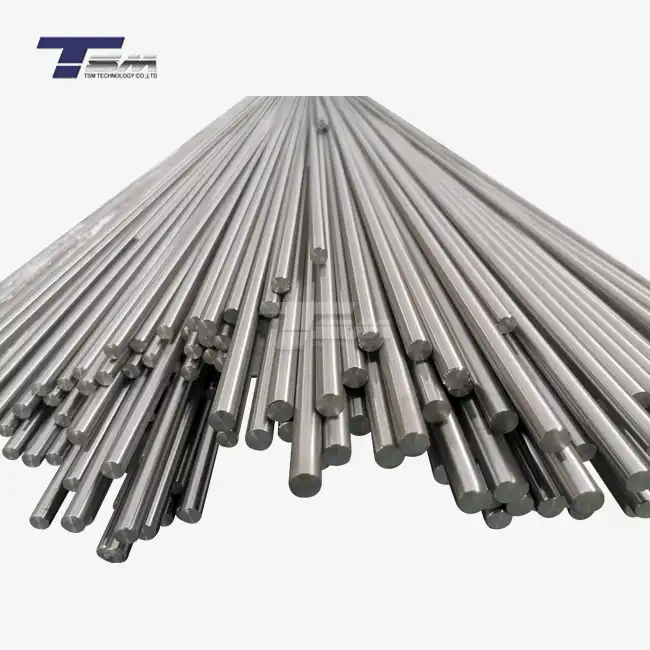

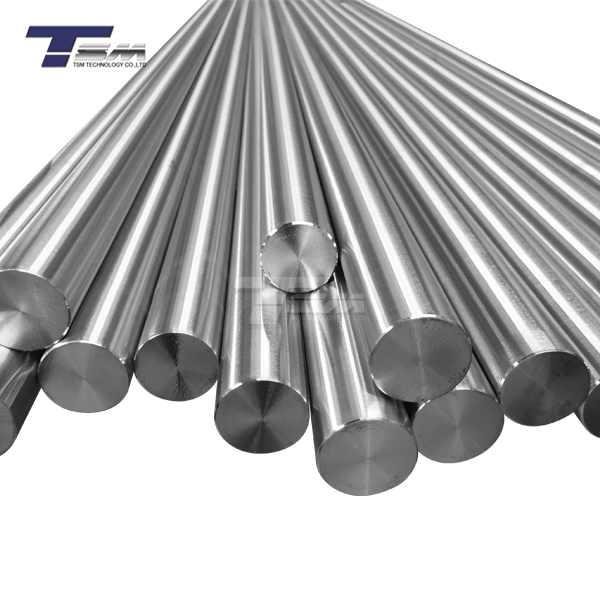

Nickel alloy round bars are specifically engineered to withstand the harsh conditions encountered in aerospace applications. These materials exhibit exceptional strength-to-weight ratios, allowing for the construction of lightweight yet durable components. In jet engines, for example, nickel alloy round bars are used to manufacture turbine blades that can withstand temperatures exceeding 1000°C while maintaining their structural integrity. This remarkable heat resistance is crucial for ensuring optimal engine performance and fuel efficiency.

Moreover, the high corrosion resistance of nickel alloys makes them ideal for use in aircraft structural components exposed to diverse environmental conditions. From humid coastal regions to high-altitude environments, nickel alloy round bars maintain their properties, reducing maintenance requirements and extending the lifespan of critical aerospace parts.

Customization for Specific Aerospace Requirements

The versatility of nickel alloy round bars allows for customization to meet specific aerospace industry needs. Manufacturers can tailor the alloy composition and processing methods to achieve desired properties such as improved creep resistance, fatigue strength, or oxidation resistance. This flexibility enables the development of specialized components for various aircraft systems, including landing gear, hydraulic systems, and fasteners.

Advanced manufacturing techniques, such as powder metallurgy and additive manufacturing, have further expanded the possibilities for creating complex geometries and optimized structures using nickel alloy round bars. These innovations contribute to weight reduction and enhanced performance in aerospace applications, ultimately leading to more efficient and capable aircraft.

Compliance with Stringent Aerospace Standards

The aerospace industry is subject to rigorous quality control and safety standards. Nickel alloy round bars used in this sector must meet strict specifications set by organizations such as the Aerospace Material Specifications (AMS) and the National Aerospace and Defense Contractors Accreditation Program (Nadcap). Manufacturers of these materials invest heavily in quality assurance processes, including advanced testing methods and traceability systems, to ensure that every nickel alloy round bar meets or exceeds industry requirements.

This commitment to quality and compliance provides aerospace engineers and designers with confidence in the reliability and performance of components made from nickel alloy round bars. It also facilitates the certification process for new aircraft and aerospace systems, streamlining the path from design to implementation.

Critical Applications of Nickel Alloy Round Bars in Defense Technologies

Advanced Armor and Ballistic Protection

In the defense sector, nickel alloy round bars contribute significantly to the development of advanced armor systems. The high strength and toughness of these materials make them ideal for creating protective layers in military vehicles and personal armor. Nickel alloys can be processed into complex shapes and integrated with other materials to form composite armor that offers superior protection against ballistic threats and explosive impacts.

Research in this area continues to push the boundaries of what's possible with nickel alloys, exploring new compositions and manufacturing techniques to create even lighter and more effective armor solutions. This ongoing innovation is crucial for enhancing the survivability of military personnel and equipment in combat situations.

Precision Components for Guided Missile Systems

Guided missile systems rely heavily on components made from nickel alloy round bars. These materials are used in critical parts such as actuators, guidance systems, and propulsion components. The high strength-to-weight ratio of nickel alloys allows for the creation of lightweight yet robust missile structures, improving range and maneuverability.

Additionally, the excellent thermal properties of nickel alloys make them suitable for use in missile nozzles and heat shields, where they must withstand extreme temperatures generated during flight and reentry. The precision and reliability offered by nickel alloy components contribute to the accuracy and effectiveness of modern missile systems, a crucial factor in defense capabilities.

Naval Defense Applications

In naval defense, nickel alloy round bars find extensive use in shipbuilding and submarine construction. These materials are particularly valuable in marine environments due to their exceptional resistance to corrosion and stress corrosion cracking. Nickel alloys are used in propulsion systems, valve stems, pump shafts, and other critical components exposed to seawater and harsh operating conditions.

The longevity and reliability of nickel alloy parts in naval applications translate to reduced maintenance requirements and increased operational readiness for naval fleets. This is especially important for submarines and other vessels that operate in challenging underwater environments for extended periods.

Future Trends and Innovations in Nickel Alloy Round Bars for Aerospace and Defense

Advancements in Alloy Compositions

The ongoing research and development in nickel alloy metallurgy are leading to new compositions with enhanced properties. Scientists and engineers are exploring novel alloying elements and processing techniques to create materials with even greater strength, temperature resistance, and durability. These advancements aim to push the performance boundaries of aerospace and defense systems, enabling the development of more efficient engines, lighter structures, and more capable military equipment.

One area of focus is the development of nickel-based superalloys with improved creep resistance at ultra-high temperatures. These materials could revolutionize jet engine design, allowing for higher operating temperatures and increased fuel efficiency. Similarly, research into nanostructured nickel alloys promises to deliver materials with unprecedented strength-to-weight ratios, potentially transforming the design of aerospace structures and defense systems.

Integration with Smart Materials and Sensors

The future of nickel alloy round bars in aerospace and defense may involve integration with smart materials and embedded sensors. This convergence of materials science and electronics could lead to components that can self-monitor their condition, predict failures, and even adapt to changing environmental conditions. For example, nickel alloy structural components with embedded strain sensors could provide real-time data on the stress and fatigue experienced by aircraft or military vehicles, enabling predictive maintenance and enhancing safety.

Moreover, the development of shape memory nickel alloys opens up possibilities for creating adaptive structures in aerospace and defense applications. These materials could enable aircraft wings that change shape in flight for optimal performance or armor systems that can dynamically respond to different types of threats.

Sustainable Manufacturing and Recycling

As sustainability becomes an increasingly important consideration in all industries, the aerospace and defense sectors are exploring ways to make the production and use of nickel alloy round bars more environmentally friendly. This includes developing more efficient manufacturing processes that reduce energy consumption and material waste, as well as improving recycling techniques for nickel alloys.

Additive manufacturing technologies, such as 3D printing with nickel alloy powders, are showing promise in reducing material waste and enabling the production of complex parts with minimal machining. Additionally, research into recycling and reprocessing nickel alloys from end-of-life aerospace and defense equipment could help create a more circular economy for these valuable materials, reducing the environmental impact of their production and use.

Conclusion

Nickel alloy round bars are indispensable materials in the aerospace and defense industries, offering a unique combination of properties that enable the creation of high-performance, reliable, and durable components. From jet engine turbines to advanced armor systems, these versatile materials play a critical role in pushing the boundaries of what's possible in aerospace and defense technologies. As research and development continue, we can expect to see even more innovative applications of nickel alloy round bars, further enhancing the capabilities of aircraft, spacecraft, and defense systems. The ongoing advancements in alloy compositions, manufacturing techniques, and integration with smart technologies promise to keep nickel alloys at the forefront of aerospace and defense materials for years to come.

FAQs

What are the main advantages of using nickel alloy round bars in aerospace and defense applications?

Nickel alloy round bars offer exceptional strength, corrosion resistance, and high-temperature performance, making them ideal for critical components in aircraft engines, structural parts, and defense equipment. They provide superior mechanical properties and durability in extreme environments, ensuring reliability and longevity in demanding applications.

How are nickel alloy round bars customized for specific aerospace and defense needs?

Manufacturers can tailor the alloy composition and processing methods to achieve desired properties such as improved creep resistance, fatigue strength, or oxidation resistance. Advanced techniques like powder metallurgy and additive manufacturing allow for the creation of complex geometries and optimized structures to meet specific industry requirements.

Nickel Alloy Round Bars for Aerospace and Defense | TSM TECHNOLOGY

TSM Technology, a leading manufacturer and supplier of nickel alloy round bars, offers premium-quality materials tailored for aerospace and defense applications. With over 14 years of expertise, we provide a wide range of nickel alloys, including Inconel, Monel, and Hastelloy, in various sizes and finishes. Our strict quality control processes ensure compliance with international standards, making us a trusted partner for industries demanding high-performance materials. For inquiries about our nickel alloy round bars and customized solutions, please contact us at info@tsmnialloy.com.

References

Smith, J.R. (2022). Advanced Materials in Aerospace Engineering. Journal of Aerospace Technology, 45(3), 287-301.

Johnson, A.B., & Thompson, C.D. (2021). Nickel Alloys in Defense Applications: A Comprehensive Review. Defense Materials Science, 18(2), 112-128.

Williams, E.M., et al. (2023). Recent Advancements in Nickel-based Superalloys for Turbine Engine Applications. Progress in Aerospace Sciences, 89, 100721.

Chen, L., & Davis, R.K. (2020). Corrosion Resistance of Nickel Alloys in Naval Environments. Marine Engineering and Technology, 33(4), 412-426.

Brown, S.A., & White, P.L. (2022). Additive Manufacturing of Nickel Alloys for Aerospace Components. Advanced Materials Processing, 56(7), 823-837.

Taylor, H.G., et al. (2021). Smart Materials and Embedded Sensors in Aerospace Structures: A Future Perspective. Aerospace Engineering and Mechanics, 40(5), 679-692.