- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

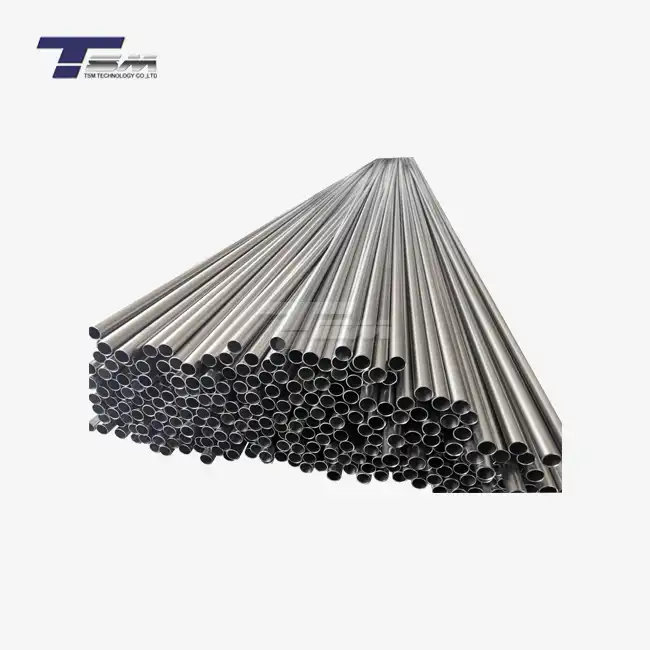

How to Select Monel 404 Tube for Marine Cooling Systems?

Selecting the right Monel 404 tube for marine cooling systems is crucial for ensuring optimal performance and longevity in harsh seawater environments. To choose the best Monel 404 tubing, consider factors such as corrosion resistance, mechanical properties, and compliance with industry standards. Evaluate the specific requirements of your marine cooling system, including operating temperatures, pressures, and fluid composition. Consult with experienced manufacturers like TSM Technology to ensure you select Monel 404 tubes that meet or exceed your project's specifications and performance expectations.

Understanding Monel 404 Tube Properties for Marine Applications

Corrosion Resistance in Seawater Environments

Monel 404 tubes excel in marine applications due to their exceptional resistance to seawater corrosion. This nickel-copper alloy forms a protective oxide layer when exposed to seawater, providing long-term protection against pitting and crevice corrosion. The material's inherent resistance to chloride stress corrosion cracking makes it ideal for marine cooling systems where exposure to saltwater is constant.

Mechanical Strength and Durability

When selecting Monel 404 tubes for marine cooling systems, consider their superior mechanical properties. With a tensile strength ranging from 450-550 MPa and yield strength of 170-200 MPa, these tubes offer excellent durability under high-pressure conditions. The alloy's ability to maintain its strength and toughness at elevated temperatures up to 300°C (570°F) ensures reliable performance in various operating conditions.

Thermal Conductivity and Heat Transfer Efficiency

Monel 404 tubes possess a thermal conductivity of 21.8 W/m·K, making them efficient for heat transfer applications in marine cooling systems. This property, combined with the material's resistance to erosion and corrosion, ensures optimal heat exchange performance over extended periods. When selecting tubing, consider the specific heat transfer requirements of your system to determine the most suitable tube dimensions and wall thickness.

Key Factors in Selecting Monel 404 Tube for Marine Cooling Systems

Dimensional Considerations

When designing marine cooling systems, selecting Monel 404 tubes with the correct dimensions is critical to ensure optimal performance. TSM Technology offers a wide range of tube sizes, with outer diameters from 6.0 to 114mm and wall thicknesses from 0.5 to 15mm. Key factors to consider include flow rate, operating pressure, and spatial constraints within the system. Custom lengths up to 15,000mm are also available, allowing engineers to tailor solutions to specific project requirements, ensuring efficient fluid transport and reliable long-term operation under demanding marine conditions.

Surface Finish Options

The surface finish of Monel 404 tubes significantly affects their performance in marine environments, influencing corrosion resistance and hydraulic efficiency. TSM Technology provides options such as bright, matte, and polished finishes to meet varying application needs. A polished or smooth surface can reduce friction and prevent fouling, enhancing fluid flow and overall system efficiency. Selecting the appropriate finish requires consideration of factors such as exposure to seawater, flow velocity, and maintenance requirements, ensuring the tube's longevity and reliable operation within the marine cooling system.

Compliance with Industry Standards

Ensuring that Monel 404 tubes meet recognized industry standards is essential for quality and compatibility. TSM Technology manufactures tubes in accordance with ASTM, JIS, AISI, GB, DIN, and EN standards, providing consistent material performance across different projects. Adhering to these standards guarantees that the tubes will meet mechanical, chemical, and dimensional requirements for marine cooling systems. When specifying Monel 404 tubes, referencing the relevant standards ensures that the selected materials integrate seamlessly into the system, offering reliability, regulatory compliance, and long-term operational efficiency.

Best Practices for Monel 404 Tube Installation and Maintenance

Proper Handling and Installation Techniques

To maximize the performance of Monel 404 tubes in marine cooling systems, follow proper handling and installation procedures. Use clean tools and work surfaces to prevent contamination. When cutting or shaping tubes, employ methods that minimize heat-affected zones, such as using sharp carbide tools with proper cooling. Ensure proper alignment and support during installation to prevent stress concentration points.

Welding and Joining Considerations

When joining Monel 404 tubes, use compatible welding techniques and filler materials. Gas tungsten arc welding (GTAW) and gas metal arc welding (GMAW) are suitable methods when using matching composition filler metals. Proper pre-cleaning and post-weld heat treatment may be necessary to maintain the alloy's corrosion resistance and mechanical properties. Consult welding guidelines specific to Monel 404 for optimal results.

Regular Inspection and Maintenance Protocols

Implement a regular inspection and maintenance program for Monel 404 tubes in marine cooling systems. Periodically check for signs of corrosion, erosion, or mechanical damage. Monitor system performance to detect any changes in heat transfer efficiency or pressure drop. Clean tubes as needed to remove marine growth or deposits that may affect heat transfer. Promptly address any issues to ensure long-term reliability and performance of the cooling system.

Conclusion

Selecting the right Monel 404 tube for marine cooling systems is essential for ensuring long-lasting performance in challenging seawater environments. By considering factors such as corrosion resistance, mechanical properties, and dimensional requirements, you can choose tubes that meet your specific needs. Partnering with experienced manufacturers like TSM Technology ensures access to high-quality Monel 404 tubes that comply with industry standards. Proper installation, welding, and maintenance practices will help maximize the longevity and efficiency of your marine cooling system, providing reliable operation in demanding offshore and marine applications.

FAQs

What makes Monel 404 tubes suitable for marine cooling systems?

Monel 404 tubes offer exceptional corrosion resistance in seawater, high strength, and excellent thermal stability, making them ideal for marine environments.

Can Monel 404 tubes be customized for specific applications?

Yes, TSM Technology offers customized sizes and processing for Monel 404 tubes to meet specific project requirements.

What certifications are available for Monel 404 tubes?

TSM Technology provides material certifications including MTC and SGS test reports, for Monel 404 tubes.

Why Choose TSM TECHNOLOGY for Your Mone 404 Tube Needs?

TSM TECHNOLOGY is your premier choice for high-quality Monel 404 tubes. With our state-of-the-art manufacturing facilities, including 3 factories, 8 production lines, and over 100 machines, we ensure a monthly supply capacity of 300 tons. Our Monel 404 (UNS N04404) tubes meet international standards like ASTM, JIS, AISI, GB, DIN, and EN. We offer customizable sizes, finishes, and processing options to meet your specific requirements. Trust in our expertise and commitment to quality for all your marine cooling system needs. For inquiries, contact us at info@tsmnialloy.com.

References

Marine Engineering Materials Handbook: Corrosion-Resistant Alloys for Seawater Applications (2022)

ASTM B165 - Standard Specification for Nickel-Copper Alloy (UNS N04400) Seamless Pipe and Tube

Offshore Technology Conference Proceedings: Advanced Materials for Marine Cooling Systems (2023)

Journal of Marine Engineering & Technology: Performance Analysis of Nickel-Copper Alloys in Seawater Heat Exchangers (2021)

Corrosion Science and Technology: Long-term Behavior of Monel Alloys in Marine Environments (2020)

International Association of Classification Societies (IACS): Guidelines for Materials Selection in Offshore Structures (2022)

Learn about our latest products and discounts through SMS or email