Understanding Alloy 400 Pipe and Its Welding Requirements

Composition and Properties of Alloy 400

Alloy 400, also known as Monel 400, is a nickel-copper alloy renowned for its exceptional corrosion resistance and strength. Composed of approximately 67% nickel and 23% copper, with small amounts of iron and manganese, this alloy exhibits remarkable durability in harsh environments. Its unique composition allows it to withstand temperatures ranging from -240°C to 480°C for long-term use, and up to 800°C for short-term applications.

The corrosion resistance of Alloy 400 is particularly noteworthy, with a corrosion rate of less than 0.025 mm/year in seawater. This makes it an ideal choice for marine engineering, chemical processing, and aerospace applications where exposure to corrosive elements is a constant concern.

Welding Challenges with Alloy 400

Welding Alloy 400 pipe presents unique challenges due to its high nickel content. The material is susceptible to hot cracking if proper precautions are not taken. Additionally, maintaining the alloy's corrosion resistance in the weld area is crucial. Welders must be mindful of heat input and cooling rates to prevent issues such as precipitation hardening, which can affect the mechanical properties of the weld.

To overcome these challenges, it's essential to use appropriate welding techniques, such as maintaining a clean work area, using proper shielding gases, and controlling interpass temperatures. The selection of the right filler metal plays a pivotal role in addressing these challenges and ensuring a high-quality weld.

Importance of Proper Filler Metal Selection

Choosing the correct filler metal is critical when welding Alloy 400 pipe. The filler metal must be compatible with the base material to ensure that the weld joint maintains the desired mechanical properties and corrosion resistance. Using an incompatible filler metal can lead to weld defects, reduced strength, and compromised corrosion resistance, potentially causing premature failure in critical applications.

The selected filler metal should closely match the chemical composition of Alloy 400 to maintain consistency in properties across the weld joint. This similarity in composition helps prevent galvanic corrosion and ensures that the weld behaves similarly to the base metal under various environmental conditions.

Recommended Welding Filler Metals for Alloy 400 Pipe

ERNiCu-7 for Gas Tungsten Arc Welding (GTAW)

ERNiCu-7 is the primary choice for gas tungsten arc welding (GTAW) of Alloy 400 pipe. This filler metal, also known as Monel Filler Metal 67, closely matches the composition of Alloy 400, containing approximately 65% nickel and 30% copper. The similarity in composition ensures excellent compatibility with the base metal, resulting in welds with comparable strength and corrosion resistance.

GTAW with ERNiCu-7 offers several advantages:

- Precise control over heat input

- High-quality, clean welds

- Minimal risk of inclusions or porosity

- Excellent for thin-walled pipes and intricate joints

When using ERNiCu-7, it's crucial to maintain proper shielding gas coverage, typically pure argon, to prevent oxidation and ensure optimal weld quality.

ENiCu-7 for Shielded Metal Arc Welding (SMAW)

For shielded metal arc welding (SMAW) of Alloy 400 pipe, ENiCu-7 electrodes are the recommended choice. These electrodes, also known as Monel Welding Electrode 187, are designed to produce welds with properties similar to the base metal. The core wire composition closely matches that of Alloy 400, ensuring excellent compatibility and weld integrity.

Benefits of using ENiCu-7 for SMAW include:

- Good weldability in all positions

- High resistance to hot cracking

- Excellent corrosion resistance in marine environments

- Suitable for both thin and thick-walled pipes

When welding with ENiCu-7 electrodes, it's important to keep the electrodes dry and use the appropriate welding parameters to achieve optimal results.

Alternative Filler Metals and Special Considerations

While ERNiCu-7 and ENiCu-7 are the primary recommended filler metals for Alloy 400 pipe, there are alternative options for specific applications:

1. ERNiCu-8: This filler metal contains a higher titanium content, which can improve weld ductility and resistance to hot cracking in certain applications.

2. ERNi-1: In cases where maximum corrosion resistance is required, this high-nickel filler metal may be used, although it can result in a slight mismatch in mechanical properties.

3. ERCuNi: For applications where a higher copper content is desired in the weld, this copper-nickel filler metal can be considered, though it may slightly reduce the overall strength of the joint.

Special considerations when selecting filler metals include:

- The specific service environment of the welded component

- Any post-weld heat treatment requirements

- Regulatory or code requirements for the application

- The welding process and position

Best Practices for Welding Alloy 400 Pipe

Preparation and Cleaning

Proper preparation is crucial for achieving high-quality welds on Alloy 400 pipe. Begin by thoroughly cleaning the pipe surfaces to remove any contaminants, oils, or oxides. Use a stainless steel wire brush or dedicated cleaning solutions designed for nickel alloys. Avoid using chlorinated solvents, as they can lead to stress corrosion cracking.

Key preparation steps include:

1. Degreasing the pipe surfaces

2. Mechanical cleaning with a stainless steel brush

3. Chemical cleaning if necessary, using approved solutions

4. Proper joint preparation, including beveling for thicker pipes

5. Ensuring proper fit-up and alignment before welding

Remember, cleanliness is paramount when welding Alloy 400. Any contaminants can lead to weld defects or compromise the corrosion resistance of the joint.

Welding Techniques and Parameters

When welding Alloy 400 pipe, employing the correct techniques and parameters is essential for achieving strong, defect-free welds. Here are some key considerations:

1. Heat Input Control: Maintain a balanced heat input to prevent overheating, which can lead to grain growth and reduced corrosion resistance. Use lower currents and travel speeds compared to welding carbon steel.

2. Interpass Temperature: Keep the interpass temperature below 150°C (300°F) to prevent hot cracking and maintain optimal mechanical properties.

3. Shielding Gas: For GTAW, use pure argon as the shielding gas. For GMAW, a mixture of argon with 25-30% helium can improve penetration and weld quality.

4. Welding Position: When possible, weld in the flat or horizontal position to improve weld quality and productivity.

5. Preheat and Post-weld Heat Treatment: Generally not required for Alloy 400, but may be necessary for thicker sections or specific applications.

Quality Control and Inspection

Ensuring the quality of Alloy 400 pipe welds is critical for maintaining the integrity and performance of the welded components. Implement a comprehensive quality control and inspection process that includes:

1. Visual Inspection: Check for surface defects, proper weld profile, and complete fusion.

2. Non-Destructive Testing:

- Radiographic testing (RT) for detecting internal defects

- Dye penetrant testing (PT) for surface crack detection

- Ultrasonic testing (UT) for weld integrity and thickness measurements

3. Mechanical Testing: - Tensile strength tests to ensure proper joint strength - Bend tests to verify ductility and fusion

4. Corrosion Testing:

- ASTM G28 testing for intergranular corrosion resistance

- Seawater immersion tests for marine applications

5. Microstructure Analysis:

- Examine weld cross-sections to verify proper fusion and absence of defects

Implement a rigorous documentation process, including welding procedure specifications (WPS) and procedure qualification records (PQR) to ensure consistency and traceability in your welding operations.

Conclusion

Selecting the appropriate welding filler metals for Alloy 400 pipe is crucial for maintaining the material's exceptional properties in welded joints. ERNiCu-7 for GTAW and ENiCu-7 for SMAW are the primary recommended filler metals, offering excellent compatibility and performance. By following best practices in preparation, welding techniques, and quality control, fabricators can ensure high-quality, durable welds that meet the demanding requirements of industries relying on Alloy 400's unique characteristics. Remember, the key to successful welding of Alloy 400 pipe lies in understanding the material's properties, selecting the right filler metal, and implementing proper welding procedures.

FAQs

Can I use stainless steel filler metals for welding Alloy 400 pipe?

It's not recommended. Stainless steel filler metals don't match the composition of Alloy 400 and can lead to reduced corrosion resistance and mechanical properties in the weld joint.

Is post-weld heat treatment necessary for Alloy 400 pipe welds?

Generally, post-weld heat treatment is not required for Alloy 400 pipe welds. However, it may be necessary for thick sections or specific applications to relieve residual stresses.

How do I prevent hot cracking when welding Alloy 400 pipe?

To prevent hot cracking, maintain proper interpass temperatures, control heat input, use the recommended filler metals, and ensure clean, contamination-free surfaces before welding.

Expert Welding Solutions for Alloy 400 Pipe | TSM TECHNOLOGY

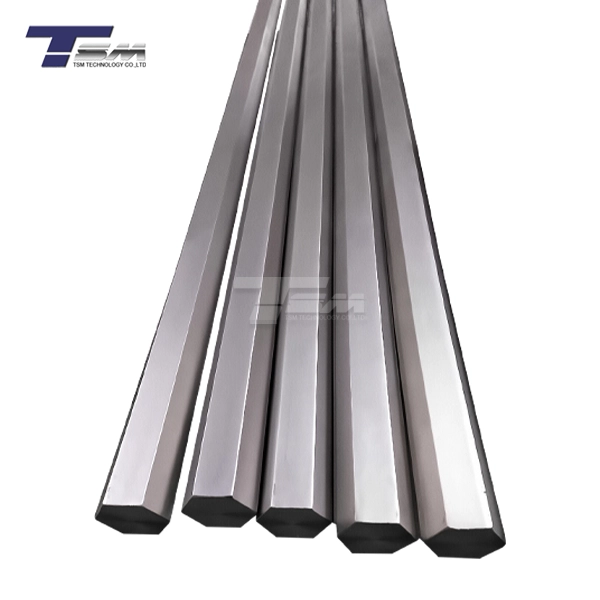

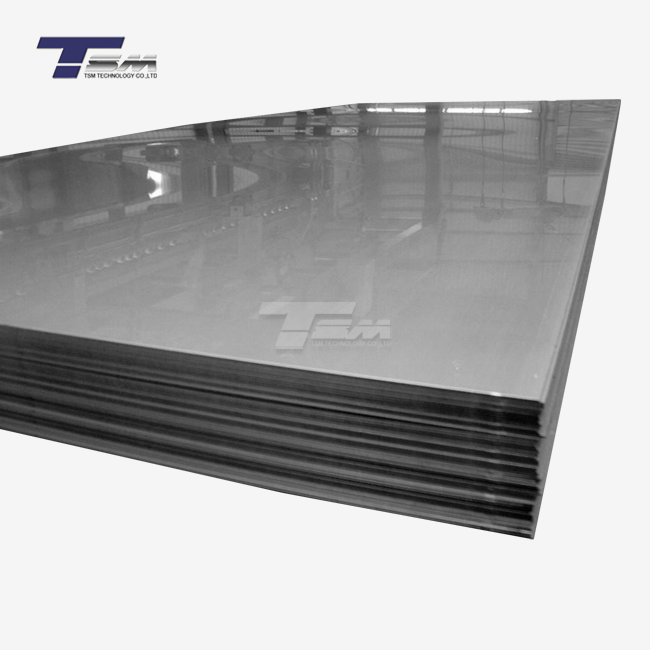

At TSM TECHNOLOGY, we specialize in providing top-quality Alloy 400 pipe and expert welding solutions. Our state-of-the-art facilities, including 3 factories with 8 production lines and over 100 advanced machines, ensure precision manufacturing of Alloy 400 pipes to ASTM B165, ASME SB165, and EN 10095 standards. We offer customization, surface treatments, and comprehensive material certifications. Trust our expertise for all your Alloy 400 pipe welding needs. Contact us at info@tsmnialloy.com for personalized support and free samples.

References

American Welding Society. (2015). Welding Handbook, Volume 4: Materials and Applications, Part 2. Miami, FL: AWS.

DuPont, J.N., Lippold, J.C., & Kiser, S.D. (2009). Welding Metallurgy and Weldability of Nickel-Base Alloys. Hoboken, NJ: John Wiley & Sons.

Special Metals Corporation. (2018). Monel Alloy 400 Technical Datasheet. New Hartford, NY: Special Metals Corporation.

ASTM International. (2020). ASTM B165-20: Standard Specification for Nickel-Copper Alloy (UNS N04400) Seamless Pipe and Tube. West Conshohocken, PA: ASTM International.

Kou, S. (2003). Welding Metallurgy, 2nd Edition. Hoboken, NJ: John Wiley & Sons.

American Society of Mechanical Engineers. (2019). ASME Boiler and Pressure Vessel Code, Section IX: Welding, Brazing, and Fusing Qualifications. New York, NY: ASME.