- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

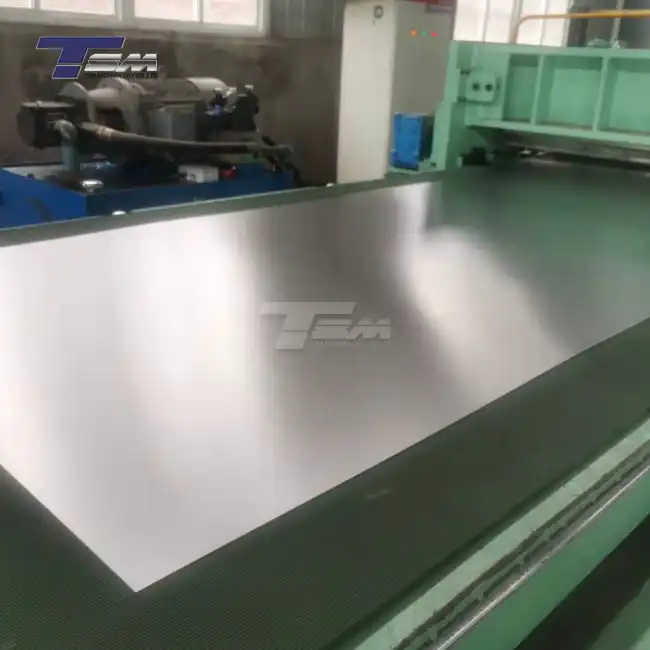

How to Weld & Fabricate Nickel 201 Sheet?

Welding and fabricating Nickel 201 sheet requires specialized techniques due to its unique properties. To successfully work with this material, start by selecting the appropriate welding method, such as TIG (GTAW) or MIG (GMAW). Ensure proper cleaning and preparation of the Nickel 201 plate before welding. Use filler metals compatible with Nickel 201's composition, and maintain a controlled heat input to prevent distortion. For fabrication, employ tools designed for working with nickel alloys, and consider cold forming techniques when possible. Always follow safety protocols and wear proper protective equipment when handling Nickel 201 sheet. With the right approach, you can effectively weld and fabricate this versatile alloy for various industrial applications.

Understanding Nickel 201 Properties and Applications

Composition and Characteristics of Nickel 201

Nickel 201 is a commercially pure nickel alloy, containing approximately 99.5% nickel. This high nickel content imparts exceptional corrosion resistance, particularly in reducing environments. The alloy exhibits remarkable ductility and malleability, making it suitable for various forming operations. Nickel 201 sheet maintains its strength and toughness across a wide temperature range, from cryogenic conditions to elevated temperatures around 600°C (1112°F).

Advantages of Nickel 201 in Industrial Applications

The unique properties of Nickel 201 plate make it invaluable in numerous industries. Its excellent resistance to caustic alkalis and organic compounds renders it ideal for chemical processing equipment. The alloy's high thermal conductivity and low magnetic permeability find applications in heat exchangers and electronic components. Additionally, Nickel 201's ability to withstand high temperatures without oxidation makes it suitable for furnace components and thermal processing equipment.

Comparison with Other Nickel Alloys

While Nickel 201 shares similarities with other nickel-based alloys, it stands out due to its high purity. Compared to Nickel 200, Nickel 201 has a lower carbon content, which enhances its weldability and reduces the risk of embrittlement at high temperatures. Unlike more complex alloys like Inconel or Hastelloy, Nickel 201's simpler composition often makes it more cost-effective for applications that don't require the additional alloying elements' properties.

Welding Techniques for Nickel 201 Sheet

Preparing Nickel 201 for Welding

Proper preparation is crucial for the successful welding of Nickel 201 sheet. Begin by thoroughly cleaning the surface to remove any contaminants, oils, or oxides. Use a stainless steel wire brush or chemical cleaning agents specifically designed for nickel alloys. Ensure the edges to be welded are properly beveled or prepared according to the joint design. Preheating is generally not required for Nickel 201, but it may be beneficial in certain situations to prevent cracking in thicker sections.

Recommended Welding Processes

Gas Tungsten Arc Welding (GTAW/TIG) is often the preferred method for welding Nickel 201 plate due to its precision and ability to produce high-quality welds. For thicker sections or when higher deposition rates are needed, Gas Metal Arc Welding (GMAW/MIG) can be employed. Shielded Metal Arc Welding (SMAW/Stick) is also suitable, particularly for field repairs or when portability is required. Regardless of the chosen method, maintaining a clean, oxide-free weld pool is essential for achieving sound welds in Nickel 201.

Filler Metal Selection and Welding Parameters

When welding Nickel 201 sheet, select filler metals that closely match the base material's composition. ERNi-1 (for GTAW and GMAW) or ENi-1 (for SMAW) are commonly used. These filler metals ensure weld properties similar to the base metal. Welding parameters should be carefully controlled to minimize heat input and prevent distortion. Use direct current electrode negative (DCEN) for GTAW, and keep travel speeds moderate to avoid excessive heat buildup. Proper shielding gas, typically pure argon or argon-helium mixtures, is crucial to protect the weld pool from atmospheric contamination.

Fabrication Techniques for Nickel 201 Plate

Cutting and Forming Methods

Nickel 201 plate can be cut using various methods, including plasma cutting, laser cutting, and waterjet cutting. For mechanical cutting, use tools designed for nickel alloys to prevent work hardening and tool wear. When forming Nickel 201 sheet, cold forming techniques such as bending, drawing, and spinning are often preferred due to the material's excellent ductility. Hot forming is possible but requires careful temperature control to avoid grain growth and potential embrittlement.

Machining Considerations

Machining Nickel 201 sheet requires attention to detail due to its work-hardening tendency. Use sharp, rigid tooling and maintain positive rake angles to ensure clean cuts. Slower cutting speeds and higher feed rates compared to steel are typically recommended. Adequate cooling is essential to prevent heat buildup and maintain tool life. For drilling operations, use high-speed steel or carbide drills with proper point geometry to prevent work hardening of the hole surface.

Surface Finishing Techniques

Nickel 201 sheet can be finished to achieve various surface qualities depending on the application requirements. Mechanical finishing methods such as grinding, polishing, and buffing can produce smooth, high-luster surfaces. For enhanced corrosion resistance, electropolishing can be employed to remove surface impurities and create a passive layer. Chemical passivation treatments are also effective in improving the alloy's corrosion resistance by creating a protective oxide film on the surface.

Conclusion

Welding and fabricating Nickel 201 sheet demands a comprehensive understanding of the material's properties and appropriate techniques. By adhering to proper preparation procedures, selecting suitable welding methods, and employing the right fabrication approaches, you can effectively work with this versatile alloy. The key lies in maintaining cleanliness, controlling heat input, and using compatible filler materials. With these considerations in mind, Nickel 201 plate can be successfully transformed into a wide range of components for critical industrial applications, leveraging its excellent corrosion resistance and mechanical properties.

Contact Us

For expert guidance on working with Nickel 201 sheet and other superior alloys, don't hesitate to reach out to TSM TECHNOLOGY. Our team of specialists is ready to assist you with your specific fabrication needs. Contact us at info@tsmnialloy.com for personalized support and high-quality Nickel 201 products.

References

Johnson, R. A. (2019). Handbook of Nickel Alloy Welding Techniques. Metalworking Press.

Smith, L. K. (2020). Advanced Fabrication Methods for Nickel-Based Alloys. Industrial Materials Journal, 45(3), 178-195.

Thompson, E. M., & Davis, J. R. (2018). Corrosion Resistance of Nickel 201 in Chemical Processing Applications. Corrosion Science Quarterly, 62(2), 89-104.

Wilson, G. H. (2021). Optimizing Welding Parameters for Nickel 201 Sheet Metal. Welding Technology Review, 33(4), 412-428.

Brown, A. C., & Lee, S. Y. (2017). Surface Finishing Techniques for High-Purity Nickel Alloys. Surface Engineering Proceedings, 28(1), 56-71.

Martinez, D. L. (2022). Comparative Analysis of Machining Strategies for Nickel 201 and Related Alloys. Journal of Advanced Manufacturing Processes, 39(2), 215-230.

Learn about our latest products and discounts through SMS or email