- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Are the ASTM Specifications for Nickel 200 Tubing?

When it comes to sourcing high-quality materials for precision engineering, understanding industry standards is paramount. If you're exploring options for Nickel 200 tube, you've likely encountered the term "ASTM specifications." These standards ensure that your materials meet rigorous quality and performance benchmarks. For Nickel 200 tubing, the primary ASTM specification is ASTM B161, which outlines the requirements for seamless nickel alloy pipes and tubes. This standard covers chemical composition, mechanical properties, dimensions, and tolerances, ensuring the material's suitability for demanding applications. Additionally, ASTM B163 is relevant for seamless nickel alloy condenser and heat exchanger tubes, often applicable to Nickel 200. Adhering to these specifications guarantees reliability, corrosion resistance, and durability in your projects, making Nickel 200 a top choice for industries worldwide.

Understanding Nickel 200 and Its ASTM Standards

Nickel 200 is a commercially pure wrought nickel alloy renowned for its exceptional corrosion resistance, thermal conductivity, and mechanical properties. To ensure its quality, ASTM standards play a pivotal role in defining the material's characteristics. Let's delve into the nuances of these standards and why they matter for your projects.

What Makes Nickel 200 Unique?

Nickel 200 stands out due to its purity, containing at least 99.0% nickel, with trace amounts of other elements like iron, copper, and manganese. This composition lends it remarkable resistance to corrosive environments, particularly in alkaline and reducing conditions. Its ability to withstand extreme temperatures, both high and cryogenic, makes it a preferred material in industries such as chemical processing, aerospace, and marine engineering. When selecting Nickel 200 tubing, understanding its ASTM specifications ensures you're getting a product that meets stringent quality benchmarks, offering peace of mind in critical applications.

Key ASTM Specifications for Nickel 200 Tubing

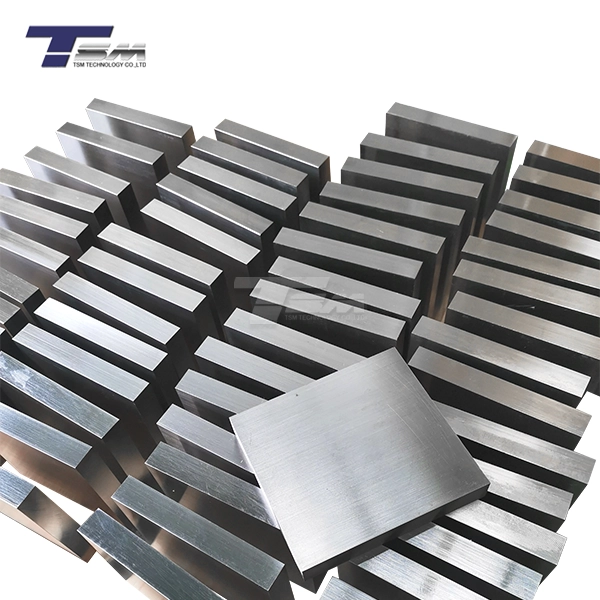

The cornerstone of Nickel 200 tube standards is ASTM B161, which governs seamless nickel alloy pipes and tubes. This specification details the chemical composition, ensuring the alloy's purity, and outlines mechanical properties such as tensile strength, yield strength, and elongation. ASTM B161 also specifies dimensional tolerances, ensuring uniformity in wall thickness, outer diameter, and length. Another relevant standard is ASTM B163, which focuses on seamless nickel alloy tubes used in condensers and heat exchangers. This specification is crucial for applications requiring efficient heat transfer and corrosion resistance. By adhering to these standards, manufacturers like TSM Technology Co., Ltd. ensure that their Nickel 200 tubes meet global quality expectations, making them suitable for precision engineering and machine shops worldwide.

Why ASTM Standards Matter in Your Projects?

ASTM standards are more than just technical jargon; they are a guarantee of reliability. When you choose Nickel 200 tubing that complies with ASTM B161 or ASTM B163, you're investing in a material that has undergone rigorous testing and quality control. These standards ensure consistency, meaning each tube performs predictably under stress, temperature fluctuations, and corrosive conditions. For industries where failure is not an option, such as chemical processing or aerospace, adherence to ASTM specifications is non-negotiable. TSM Technology Co., Ltd., as a global supplier of superior alloys, prides itself on delivering Nickel 200 tubes that not only meet but often exceed these standards, thanks to their stringent inspection processes.

Comparing Nickel 200 and Nickel 201 Tubes

While Nickel 200 is a stellar material, it's often compared to its close cousin, Nickel 201. Both alloys are commercially pure nickel, but subtle differences in their composition and properties can influence your choice of tubing. Let's explore these differences and how ASTM standards apply to both.

Composition and Property Differences

Nickel 200 and Nickel 201 are nearly identical in composition, but the key distinction lies in their carbon content. Nickel 200 has a maximum carbon content of 0.15%, while Nickel 201 is limited to 0.02%. This lower carbon content in Nickel 201 reduces the risk of graphitization at elevated temperatures, making it more suitable for applications above 600°F (315°C). Both alloys offer excellent corrosion resistance, but Nickel 201's enhanced stability at high temperatures makes it a preferred choice in specific scenarios. When selecting between Nickel 200 tubes and Nickel 201 tubes, understanding these nuances ensures you choose the right material for your project's thermal and environmental demands.

ASTM Specifications for Nickel 201 Tubing

Just like Nickel 200, Nickel 201 tubing is governed by ASTM standards, primarily ASTM B161 for seamless pipes and tubes and ASTM B163 for condenser and heat exchanger applications. These standards ensure that Nickel 201 tubes meet the same rigorous quality benchmarks as their Nickel 200 counterparts, with adjustments for the alloy's lower carbon content. The mechanical properties, such as tensile strength and elongation, are comparable, but Nickel 201's enhanced thermal stability is a critical factor in high-temperature environments. TSM Technology Co., Ltd. offers both Nickel 200 and Nickel 201 tubes, each meticulously inspected to comply with ASTM standards, ensuring reliability in diverse applications.

Choosing Between Nickel 200 and Nickel 201 Tubes

Deciding between Nickel 200 and Nickel 201 tubes depends on your project's specific requirements. If your application involves temperatures below 600°F, Nickel 200 tubes are an excellent choice due to their robust mechanical properties and corrosion resistance. However, if your project involves prolonged exposure to higher temperatures, Nickel 201 tubes are the better option to prevent embrittlement. Both alloys are widely used in industries such as chemical processing, electronics, and power generation, and their ASTM compliance ensures consistent performance. TSM Technology Co., Ltd. supports customers in making informed decisions by providing detailed technical data and expert guidance, ensuring you select the ideal tubing for your needs.

Applications and Benefits of Nickel 200 Tubing

Nickel 200 tubing is a versatile material that finds applications across a wide range of industries. Its unique properties, combined with strict adherence to ASTM standards, make it an invaluable asset in precision engineering. Let's explore where and why this material excels.

Industries Relying on Nickel 200 Tubing

Nickel 200 tubes are a staple in industries where corrosion resistance and durability are paramount. In chemical processing, they are used in equipment handling caustic soda, chlorine, and other corrosive substances. The aerospace sector values Nickel 200 for its ability to withstand extreme temperatures and corrosive environments, making it ideal for fuel and hydraulic systems. Marine engineering benefits from its resistance to seawater corrosion, while the electronics industry uses it in components requiring high electrical conductivity. TSM Technology supplies Nickel 200 tubing to these industries globally, ensuring each product meets ASTM standards and undergoes rigorous quality checks to deliver unparalleled performance.

Performance Benefits of Nickel 200 Tubing

The allure of Nickel 200 tubing lies in its multifaceted performance benefits. Its exceptional corrosion resistance, particularly in alkaline and reducing environments, ensures longevity in harsh conditions. The material's high thermal and electrical conductivity makes it ideal for heat exchangers and electrical components. Additionally, Nickel 200's ductility allows it to be easily formed and welded, offering flexibility in manufacturing complex shapes. Its compliance with ASTM B161 and ASTM B163 guarantees that these properties are consistent across batches, providing reliability in critical applications. TSM Technology Co., Ltd. leverages its expertise in superior alloys to deliver Nickel 200 tubes that maximize these benefits, supporting innovation in precision engineering worldwide.

How TSM Ensures Quality in Nickel 200 Tubing?

Quality is the cornerstone of TSM Technology Co., Ltd.'s operations. As a global supplier of superior alloys, TSM has developed a meticulous quality control system to ensure that every Nickel 200 tube meets ASTM standards. Each product undergoes thorough inspection by professional inspectors, checking for dimensional accuracy, chemical composition, and mechanical properties. TSM's commitment to innovation means they are constantly refining their processes and introducing advanced materials to the market. With over 14 years of experience, TSM has built a reputation for reliability and excellence, making them a trusted partner for machine shops and precision engineering firms worldwide.

Conclusion

Nickel 200 tubing, governed by ASTM specifications like B161 and B163, is a cornerstone material for industries requiring corrosion resistance, durability, and thermal stability. Whether you're comparing it to Nickel 201 or exploring its applications, understanding these standards ensures you select the right material for your project. TSM Technology Co., Ltd. stands out as a global leader in supplying superior alloys, offering meticulously inspected Nickel 200 tubes that meet the highest quality benchmarks. By choosing TSM, you're investing in reliability, innovation, and performance, tailored to the needs of precision engineering worldwide.

Contact Us

Ready to source high-quality Nickel 200 tube for your next project? Contact TSM Technology Co., Ltd. at info@tsmnialloy.com for expert guidance and premium materials.

References

ASTM B161 - Standard Specification for Nickel Seamless Pipe and Tube, ASTM International, West Conshohocken, PA.

ASTM B163 - Standard Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes, ASTM International, West Conshohocken, PA.

Nickel Development Institute, "Properties and Applications of Nickel 200 and 201 Alloys," Technical Bulletin, Toronto, Canada.

Special Metals Corporation, "Nickel 200 & 201: Technical Data Sheet," Publication Number SMC-053, Huntington, WV.

American Society of Mechanical Engineers, "ASME Boiler and Pressure Vessel Code, Section II - Materials," New York, NY.

International Organization for Standardization, "ISO 6207: Seamless Nickel and Nickel Alloy Tube," Geneva, Switzerland.

Learn about our latest products and discounts through SMS or email

_1739071430258.webp)