- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Incoloy 800 Tubes - Material Selection and Properties

Incoloy 800 tubes are a cornerstone in high-performance industrial applications, offering exceptional resistance to corrosion, oxidation, and carburization at elevated temperatures. These nickel-iron-chromium alloy tubes excel in extreme environments, making them indispensable in chemical processing, energy production, and heat exchange systems. With their unique composition, Incoloy 800 pipes maintain structural integrity and mechanical properties under intense thermal stress, ensuring reliability in critical operations. This article delves into the material selection criteria, properties, and applications of Incoloy 800 tubing, providing valuable insights for engineers and procurement specialists in demanding industrial sectors.

Composition and Properties of Incoloy 800 Tubes

Chemical Composition

Incoloy 800 tubes are carefully engineered with a balanced chemical composition, primarily consisting of 30–35% nickel, 19–23% chromium, and a minimum of 39.5% iron. In addition, small quantities of carbon, manganese, silicon, copper, and aluminum are included to enhance the alloy’s strength, thermal stability, and corrosion resistance. This precise combination of elements ensures that Incoloy 800 maintains excellent performance in harsh operating conditions, including high-temperature environments and chemically aggressive atmospheres, making it a reliable choice for demanding industrial applications.

Mechanical Properties

The mechanical properties of Incoloy 800 tubing are highly reliable across a wide range of temperatures. The alloy maintains impressive tensile strength, yield strength, and elongation even when exposed to elevated temperatures up to 1600°F (871°C). This high thermal stability prevents deformation or weakening under prolonged heat exposure. Such characteristics make Incoloy 800 tubes ideal for critical applications, including heat exchangers, chemical reactors, and furnace components, where maintaining consistent mechanical performance under extreme thermal stress is essential for safety and operational efficiency.

Corrosion Resistance

Incoloy 800 tubing exhibits exceptional corrosion resistance, allowing it to perform reliably in a variety of aggressive environments. The alloy withstands both oxidizing and reducing media, making it versatile for use in chemical processing, petrochemical, and power generation industries. Additionally, Incoloy 800 demonstrates strong resistance to stress-corrosion cracking, particularly in chloride-ion-containing environments, which is critical for long-term service reliability. Its combination of high-temperature performance and corrosion resistance ensures that components remain durable and safe under demanding industrial conditions.

Manufacturing Process and Quality Control

Tube Fabrication Techniques

Incoloy 800 tubes are produced using advanced manufacturing techniques to guarantee uniform quality and reliable performance. The fabrication process generally begins with hot extrusion, which shapes the alloy into rough tubes, followed by cold drawing to achieve precise dimensions and enhanced mechanical properties. Seamless tubes are typically used in critical applications where maximum structural integrity is required, while welded tubes provide a cost-effective alternative for less demanding uses. These controlled methods ensure that each tube meets stringent industrial requirements.

Heat Treatment

Heat treatment is essential for optimizing the mechanical and chemical properties of Incoloy 800 tubes. The process involves solution annealing at high temperatures, typically ranging from 1850°F to 2050°F (1010°C to 1121°C), followed by rapid cooling. This controlled thermal process enhances tensile strength, ductility, and corrosion resistance, ensuring that the tubes perform reliably in harsh environments. Proper heat treatment allows the alloy to reach its full potential, making it suitable for applications in chemical processing, power generation, and high-temperature industrial systems.

Quality Assurance Measures

Stringent quality control is maintained throughout the production of Incoloy 800 tubing to ensure consistent performance and reliability. Non-destructive testing techniques, such as ultrasonic testing and eddy current inspection, are employed to detect structural defects, cracks, or inconsistencies in the tubes. Compliance with international standards, including ASTM B163, ASTM B407, and ASTM B514, guarantees that every tube meets rigorous specifications. These quality assurance measures provide confidence in the material’s integrity, dimensional accuracy, and suitability for demanding industrial applications requiring long-term durability and safety.

Applications and Industry-Specific Uses

Energy Sector

In the energy sector, Incoloy 800 tubes find extensive use in power generation systems. They are crucial components in steam generators, heat exchangers, and boiler tubes, where their resistance to high-temperature corrosion and oxidation is paramount. Nuclear power plants also rely on Incoloy 800 piping for their steam generators due to the material's stability and longevity in demanding environments.

Chemical Processing

The chemical processing industry benefits greatly from Incoloy 800 tubing and Incoloy 800 pipe. These pipes are used in ethylene furnace quench systems, where their resistance to carburization and metal dusting is essential. They also play a vital role in the construction of reactors and process vessels handling corrosive chemicals at elevated temperatures.

Petrochemical Applications

In petrochemical plants, Incoloy 800 pipes are indispensable for handling aggressive media at high temperatures. They are used in reformer tubes, cracking furnaces, and heat exchangers, where their ability to withstand sulfidation attack and maintain dimensional stability is crucial for operational efficiency and safety.

Conclusion

Incoloy 800 tubes and Incoloy 800 pipe represent a pinnacle in material engineering for high-temperature, corrosive environments. Their unique combination of mechanical strength, thermal stability, and corrosion resistance makes them indispensable in critical industrial applications. As industries continue to push the boundaries of operational conditions, the demand for Incoloy 800 piping is expected to grow. Engineers and procurement specialists should consider Incoloy 800 tubes when reliability and performance under extreme conditions are non-negotiable. By understanding the properties, manufacturing processes, and applications of this exceptional alloy, industries can make informed decisions to enhance their operational efficiency and longevity.

FAQs

What are the key advantages of using Incoloy 800 tubes?

Incoloy 800 tubes offer exceptional resistance to high-temperature corrosion, oxidation, and carburization. They maintain mechanical properties at elevated temperatures and have excellent fabricability.

In what temperature range can Incoloy 800 pipes be used?

Incoloy 800 pipes can effectively operate in temperatures ranging from cryogenic to 1600°F (871°C), making them suitable for a wide range of high-temperature applications.

How does Incoloy 800 compare to other high-temperature alloys?

Compared to many other alloys, Incoloy 800 offers a superior balance of high-temperature strength, corrosion resistance, and cost-effectiveness, making it a preferred choice in many industrial applications.

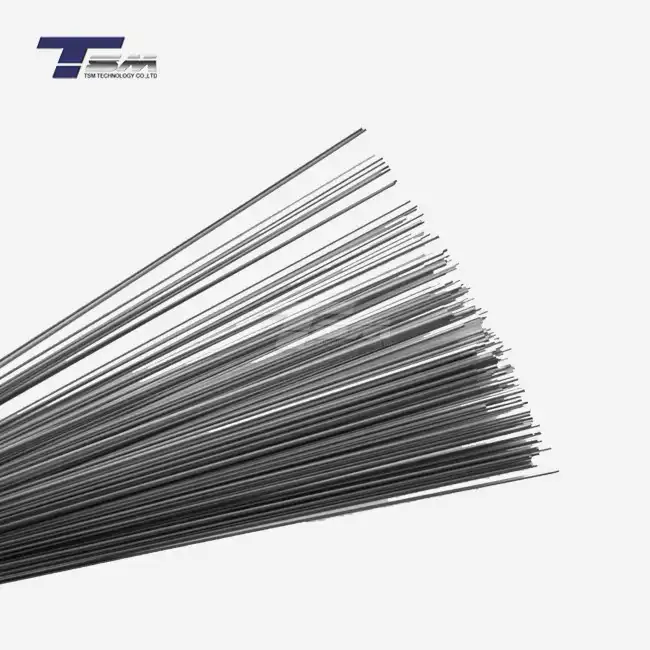

Choose Quality Incoloy 800 Tubes | TSM TECHNOLOGY

TSM Technology, a leading Incoloy 800 tube manufacturer and supplier since 2011, offers premium-quality tubing solutions. With our state-of-the-art production facilities and rigorous quality control, we ensure exceptional performance and reliability. Our Incoloy 800 tubes, available in various specifications, cater to diverse industrial needs. For expert advice or to request a quote, contact us at info@tsmnialloy.com. Trust TSM Technology for superior Incoloy 800 tubing that meets your most demanding applications.

References

Smith, J.R. (2019). "High-Temperature Alloys in Industrial Applications: A Comprehensive Review." Journal of Materials Engineering and Performance, 28(9), 5423-5442.

Chen, L. et al. (2020). "Corrosion Behavior of Incoloy 800 in Simulated Nuclear Power Plant Environments." Corrosion Science, 163, 108284.

Williams, D.B. (2018). "Microstructural Evolution of Incoloy 800 During High-Temperature Service." Materials Characterization, 142, 144-152.

Johnson, A.K. & Lee, S.Y. (2021). "Advances in Manufacturing Techniques for High-Performance Nickel Alloy Tubes." Journal of Manufacturing Processes, 61, 619-634.

Garcia-Diaz, M. et al. (2022). "Comparative Study of Incoloy 800 and Alternative Alloys in Petrochemical Applications." Industrial & Engineering Chemistry Research, 61(2), 846-857.

Thompson, R.W. (2020). "Long-Term Performance of Incoloy 800 Tubes in Nuclear Steam Generators: A 30-Year Perspective." Nuclear Engineering and Design, 366, 110742.

Learn about our latest products and discounts through SMS or email