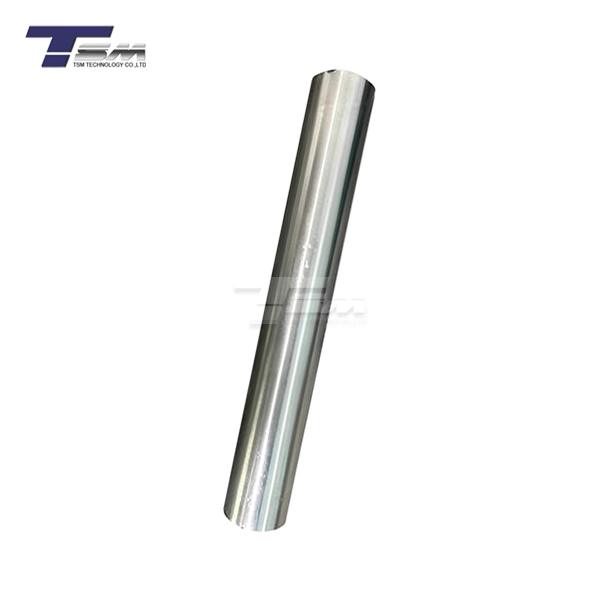

Understanding Monel 400 Tube Specifications

Composition and Properties of Monel 400

Monel 400 is a high-performance nickel-copper alloy, typically containing about 63% nickel and 31% copper, with minor amounts of iron, manganese, and silicon. This carefully balanced composition provides exceptional resistance to corrosion in seawater, acidic solutions, and a variety of industrial chemicals. In addition to its outstanding corrosion resistance, Monel 400 exhibits excellent mechanical strength, toughness, and durability over a wide temperature range. These properties make it highly suitable for demanding applications in marine, chemical processing, and oil and gas industries.

Standard Dimensions and Tolerances

Monel 400 tubing and Monel tubing are manufactured to conform with widely recognized international standards, including ASTM B163 and ASME SB163, which define acceptable ranges for outside diameter (OD), wall thickness (WT), and overall length. Typical OD ranges from 6.0 mm to 114 mm, while wall thicknesses vary between 0.5 mm and 15 mm. Tubes can reach lengths up to 15,000 mm depending on diameter and wall thickness. Adherence to these standards ensures consistent dimensional quality and compatibility with industrial piping systems and equipment.

Manufacturing Methods and Their Impact on Dimensions

The production method has a direct effect on Monel 400 tube dimensions, mechanical properties, and consistency. Seamless tubes, produced through extrusion and cold drawing, provide superior strength, dimensional accuracy, and uniform wall thickness. Welded tubes, although more economical for larger diameters, may display slight variations in wall thickness near the weld seam. Understanding the differences between seamless and welded manufacturing processes is critical for selecting the most suitable Monel 400 tubing to meet specific performance, reliability, and dimensional requirements in various industrial applications.

Selecting the Right Monel 400 Pipe Size for Your Application

Factors Influencing Size Selection

Choosing the correct Monel 400 pipe size involves considering several factors:

- Pressure requirements: Thicker walls are necessary for high-pressure applications.

- Flow rate: The inner diameter affects fluid velocity and pressure drop.

- Temperature: Thermal expansion and material strength at operating temperatures must be accounted for.

- Corrosion allowance: Additional wall thickness may be needed in highly corrosive environments.

- Weight considerations: Especially important in aerospace and offshore applications.

Industry-Specific Size Requirements

Different industries have unique requirements for Monel 400 tubing:

- Marine: Heat exchangers often use tubes with OD ranging from 15 to 25 mm and wall thicknesses of 1.2 to 2.0 mm.

- Chemical processing: Larger diameter pipes (50-100 mm OD) with thicker walls (3-10 mm) are common for handling corrosive fluids.

- Aerospace: Precision tubing with tight tolerances, typically 6-12 mm OD and 0.5-1.5 mm wall thickness.

- Oil and gas: Downhole tubing requires high strength and corrosion resistance, often utilizing 60-90 mm OD tubes with 5-10 mm walls.

Custom Sizing and Special Orders

While standard sizes cover most applications, custom Monel 400 tubing can be manufactured to meet specific project requirements. This may include non-standard diameters, wall thicknesses, or lengths. Working with a reputable manufacturer ensures that custom orders meet the same quality standards as standard products, with proper material certification and testing.

Monel 400 Tube Performance and Quality Considerations

Material Testing and Certification

Quality assurance for Monel 400 tubes involves rigorous testing:

- Chemical composition analysis to verify alloy content

- Mechanical property testing, including tensile strength and yield point

- Non-destructive testing such as ultrasonic or eddy current inspection

- Hydrostatic pressure testing to ensure integrity

Proper certification, including material test reports (MTRs), is essential for traceability and compliance with industry standards.

Surface Finish and Tolerances

The surface finish of Monel 400 tubing affects its performance in corrosive environments. A smooth, defect-free surface enhances corrosion resistance and reduces the risk of localized attacks. Tight dimensional tolerances are crucial for applications requiring precise fits or consistent flow characteristics. High-quality Monel 400 pipes typically have tolerances of ±0.1 mm on OD and ±10% on wall thickness for seamless tubes.

Long-Term Performance and Lifecycle Considerations

When selecting Monel 400 tubing, it's important to consider the long-term performance:

- Corrosion rates in the intended environment

- Fatigue resistance under cyclic loading

- Potential for stress corrosion cracking in certain conditions

- Maintenance requirements and inspection intervals

Proper sizing and material selection can significantly extend the service life of Monel 400 components, reducing lifecycle costs and improving system reliability.

Conclusion

Selecting the appropriate Monel 400 tube sizes and dimensions is crucial for ensuring optimal performance and longevity in demanding applications. By understanding the standard specifications, manufacturing processes, and application-specific requirements, engineers and procurement specialists can make informed decisions that balance performance, cost, and reliability. As industries continue to push the boundaries of material performance, Monel 400 remains a versatile and reliable choice for corrosion-resistant tubing across a wide range of sizes and applications.

FAQs

What is the maximum length available for Monel 400 tubes?

The maximum length for Monel 400 tubes can reach up to 15,000 mm, depending on the specific diameter and wall thickness combination.

Are custom sizes available for Monel 400 tubing?

Yes, custom sizes and processing are supported to meet specific project requirements.

What are the typical applications for Monel 400 tubes?

Monel 400 tubes are commonly used in marine environments, chemical processing, aerospace, oil and gas, and power generation industries.

How long does it typically take to deliver Monel 400 tubes?

Delivery time usually ranges from 10 to 25 days, depending on the order quantity and specifications.

Complete Guide to Monel 400 Tube Sizes and Dimensions | TSM TECHNOLOGY

TSM Technology, a leading Monel 400 tube manufacturer and supplier since 2011, offers a comprehensive range of sizes and dimensions to meet diverse industry needs. With our state-of-the-art facilities and strict quality control, we ensure superior corrosion-resistant Monel tubing for critical applications. For expert guidance on selecting the right Monel 400 pipe for your project, contact our team at info@tsmnialloy.com.

References

ASTM International. (2020). "ASTM B163 - Standard Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes"

ASM International. (2018). "Handbook of Corrosion-Resistant Nickel Alloys"

Special Metals Corporation. (2019). "Monel alloy 400 Technical Data Sheet"

American Society of Mechanical Engineers. (2021). "ASME Boiler and Pressure Vessel Code, Section II: Materials"

Nickel Institute. (2022). "Nickel-Copper Alloys: Properties and Applications"

Journal of Materials Engineering and Performance. (2020). "Corrosion Behavior of Monel 400 in Marine Environments"

_1739070074580.webp)