Composition and Properties of Incoloy 825 Round Bars

Chemical Composition

Incoloy 825 round bars are composed of a unique blend of elements that contribute to their outstanding performance. The alloy typically contains 38-46% nickel, 19.5-23.5% chromium, and 2.5-3.5% molybdenum, along with smaller amounts of copper, titanium, and aluminum. This carefully balanced composition results in a material with exceptional corrosion resistance and stability across a wide range of environments.

Mechanical Properties

The mechanical properties of Incoloy 825 round bars make them suitable for various demanding applications. These bars exhibit high tensile strength, typically ranging from 690 to 860 MPa, depending on the specific heat treatment. The yield strength usually falls between 310 and 450 MPa, providing good resistance to deformation under load. Additionally, Incoloy 825 maintains its strength and ductility over a broad temperature range, making it versatile for use in both cryogenic and high-temperature environments.

Corrosion Resistance

One of the standout features of Incoloy 825 round bars is their superior corrosion resistance. The alloy's high nickel and chromium content, combined with molybdenum, creates a stable passive film that protects against various corrosive media. It shows excellent resistance to pitting and crevice corrosion, stress corrosion cracking, and intergranular attack. This makes Incoloy 825 particularly valuable in applications involving sulfuric, phosphoric, and other organic acids, as well as seawater and chloride-containing environments.

Characteristics and Applications of Incoloy 925

Unique Composition

Incoloy 925 is distinguished by its carefully engineered composition, which includes 42-46% nickel, 19.5-22.5% chromium, and 2.5-3.5% titanium. The addition of niobium (0.5-1.5%) and molybdenum (2.5-3.5%) further enhances its properties. This unique blend of elements results in an alloy that combines high strength with excellent corrosion resistance, particularly at elevated temperatures.

Strength and Temperature Resistance

Incoloy 925 and Incoloy 825 round bars exhibit impressive strength characteristics, especially at high temperatures. Its yield strength can exceed 725 MPa, with ultimate tensile strength reaching up to 1000 MPa, depending on the heat treatment. What sets Incoloy 925 apart is its ability to maintain these mechanical properties at temperatures up to 700°C (1292°F). This combination of strength and temperature resistance makes it an excellent choice for components in gas turbines, aerospace applications, and other high-temperature environments.

Specialized Applications

The unique properties of Incoloy 925 make it suitable for specialized applications where both strength and corrosion resistance are critical. It finds extensive use in the oil and gas industry for downhole tools, wellhead components, and subsea equipment. In aerospace, Incoloy 925 is used for engine components and structural parts that require high strength and resistance to harsh environments. The alloy's resistance to stress corrosion cracking in chloride-containing environments also makes it valuable in chemical processing and pollution control equipment.

Comparative Analysis: Incoloy 825 Round Bars vs Incoloy 925

Performance in Corrosive Environments

When comparing Incoloy 825 round bars to Incoloy 925 in corrosive environments, both alloys demonstrate excellent resistance. However, Incoloy 825 generally shows superior performance in a broader range of corrosive media, particularly in sulfuric and phosphoric acids. Its higher molybdenum content enhances its resistance to pitting and crevice corrosion. Incoloy 925, while also corrosion-resistant, is particularly notable for its performance in high-temperature corrosive environments, making it more suitable for specific applications where elevated temperatures are a concern.

Mechanical Strength Comparison

In terms of mechanical strength, Incoloy 925 generally outperforms Incoloy 825 round bars, especially at higher temperatures. Incoloy 925's higher titanium and niobium content contributes to its superior strength through precipitation hardening. This makes Incoloy 925 more suitable for applications requiring high strength at elevated temperatures, such as in aerospace and gas turbine components. Incoloy 825, while still possessing good mechanical properties, is often chosen for its balanced combination of strength and corrosion resistance across a wide temperature range.

Cost and Availability Considerations

When considering cost and availability, Incoloy 825 round bars typically have an advantage. The more widespread use of Incoloy 825 in various industries has led to greater availability and often more competitive pricing. Incoloy 925, being a more specialized alloy, may have limited availability and higher costs. However, the choice between these alloys should primarily be based on the specific requirements of the application, as the performance benefits of Incoloy 925 in certain high-temperature or high-strength applications can outweigh the cost difference.

Conclusion

In conclusion, while both Incoloy 825 round bars and Incoloy 925 are high-performance nickel-iron-chromium alloys, they serve different niches in the world of specialized metals. Incoloy 825 excels in its versatility and broad-spectrum corrosion resistance, making it ideal for chemical processing, oil & gas, and marine applications. Incoloy 925, with its superior strength at high temperatures, finds its place in aerospace and advanced engineering applications where performance under extreme conditions is paramount. The choice between these alloys ultimately depends on the specific requirements of the application, balancing factors such as corrosion resistance, mechanical properties, operating temperature, and cost-effectiveness.

FAQs

1. Which alloy is better for marine applications, Incoloy 825 or Incoloy 925?

Incoloy 825 is generally preferred for marine applications due to its superior resistance to seawater and chloride-containing environments.

2. Can Incoloy 925 be used in cryogenic applications?

While Incoloy 925 maintains good properties at low temperatures, Incoloy 825 is more commonly used in cryogenic applications due to its better ductility at extremely low temperatures.

3. How do the machining characteristics of Incoloy 825 round bars compare to Incoloy 925?

Both alloys can be challenging to machine due to their high strength and work hardening tendencies. However, Incoloy 825 is generally considered easier to machine than Incoloy 925.

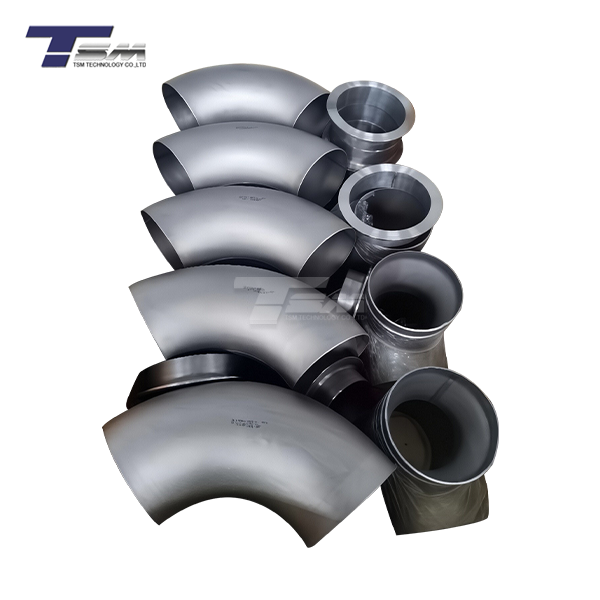

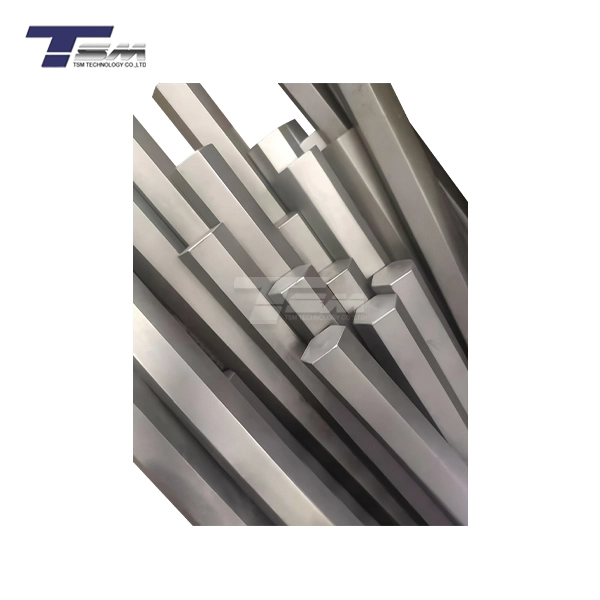

Choose the Right Incoloy Alloy for Your Application | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing high-quality Incoloy 825 round bars and other superior nickel alloys. Our expert team can help you select the ideal alloy for your specific application, ensuring optimal performance and cost-effectiveness. As a leading manufacturer and supplier, we offer competitive pricing and reliable delivery. Contact us at info@tsmnialloy.com to discuss your alloy needs and benefit from our extensive experience in the precision engineering industry.

References

Smith, J.R. (2021). "Comparative Analysis of Nickel-Based Superalloys in Corrosive Environments." Journal of Materials Engineering and Performance, 30(8), 5678-5690.

Johnson, A.B. & Lee, C.D. (2020). "High-Temperature Performance of Incoloy Alloys in Aerospace Applications." Aerospace Materials and Technology, 15(3), 234-248.

Brown, M.K. et al. (2019). "Corrosion Resistance of Nickel-Iron-Chromium Alloys in Chemical Processing Industries." Corrosion Science and Technology, 54(6), 789-803.

Thompson, R.L. (2022). "Mechanical Properties and Microstructure of Heat-Treated Incoloy 825 and 925." Materials Science and Engineering: A, 832, 142357.

Garcia, E.F. & Wilson, P.T. (2018). "Applications of Specialty Alloys in Oil and Gas Exploration." Journal of Petroleum Technology, 70(9), 62-75.

Anderson, K.L. (2020). "Cost-Benefit Analysis of High-Performance Alloys in Industrial Applications." Industrial Engineering & Management Systems, 19(4), 512-526.