- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Applications and Properties of Inconel 601

When engineers and designers search for a material that can withstand extreme heat and corrosive environments, Inconel 601 frequently emerges as a premier choice. This nickel-chromium alloy is renowned for its outstanding resistance to high-temperature oxidation, a critical property for applications extending up to 1250°C (2282°F). Its unique chemical composition, which includes a significant addition of aluminum, allows it to form a tightly adherent and protective oxide scale, preventing spalling even under severe thermal cycling. This resilience, combined with excellent mechanical strength and resistance to carburization, makes Alloy 601 indispensable in industries ranging from thermal processing and chemical manufacturing to power generation, where reliability and longevity in harsh conditions are non-negotiable.

Unpacking the Superior Properties of Inconel 601

What gives this nickel alloy its formidable reputation? The answer lies in a carefully balanced chemical composition that delivers a trifecta of high-temperature performance characteristics. Understanding these properties is key to leveraging the full potential of this exceptional material in demanding applications.

Exceptional High-Temperature Oxidation Resistance

The standout feature of Inconel 601 is its remarkable resistance to oxidation at elevated temperatures. This is primarily due to its high chromium content and a crucial addition of aluminum. When exposed to heat, these elements work together to form a very stable, passive, and self-healing oxide layer on the material's surface. Unlike the oxide layers on some other alloys, this one adheres tenaciously, resisting spalling during cyclic heating and cooling. This attribute ensures component integrity and longevity in environments like industrial furnaces and gas turbines, where thermal fluctuations are constant.

Robust Mechanical Strength and Stability

High temperatures can compromise the structural integrity of many metals, but Alloy 601 maintains impressive mechanical strength. It exhibits high creep-rupture strength, which is the ability to resist deformation under a constant load at high temperatures over time. This makes it a reliable material for load-bearing components in heat-treating fixtures, baskets, and structural parts in industrial heating systems. Its solid-solution-strengthened matrix provides stability and strength without the need for precipitation-hardening heat treatments, simplifying its use in manufacturing.

- Typical Tensile Strength (Annealed, Room Temp): 80-100 ksi (550-690 MPa)

- Typical Yield Strength (Annealed, Room Temp): 30-50 ksi (205-345 MPa)

Resistance to Carburization and Other Corrosive Environments

Beyond simple oxidation, many industrial processes involve other forms of high-temperature corrosion. Inconel 601 demonstrates excellent resistance to carburization - the absorption of carbon from the environment, which can make materials brittle. Its high nickel content also provides good resistance to nitriding and other reducing atmospheres. Furthermore, in aqueous conditions, the chromium content offers solid resistance to corrosive solutions and acids, making it a versatile choice for equipment in chemical processing plants that may face both high temperatures and chemical exposure.

Where Does Inconel 601 Shine? Key Industrial Applications

The unique combination of properties discussed above translates into a wide array of practical uses across some of the most demanding industries. This nickel-chromium alloy is not just a laboratory curiosity; it is a workhorse material that solves real-world engineering challenges.

Heat Treating and Industrial Furnaces

This is arguably the primary domain for Inconel 601. Its ability to withstand extreme heat and thermal cycling makes it the ideal material for components within industrial furnaces. You will find it used for:

- Radiant tubes, muffles, and retorts: These components must contain heat and processing atmospheres without degrading.

- Baskets and fixtures: Used to hold parts during heat treatment, they must maintain their shape and strength through countless cycles.

- Conveyor belts and roller hearths: Its strength and wear resistance are crucial for moving materials through high-temperature zones.

Chemical and Petrochemical Processing

The chemical industry requires materials that can handle aggressive media at elevated temperatures. Inconel 601 is frequently specified for equipment like process heaters, condenser tubes in sour water stripping, and insulating cans in ammonia reformers. Its resistance to both oxidation and sulfidation makes it a durable choice for combustion systems and catalyst support grids in nitric acid production, where material failure could have catastrophic consequences.

Power Generation and Aerospace Components

In power generation, reliability is paramount. Alloy 601 is used for superheater tube supports, grid barriers, and ash-handling systems, where it resists hot gas corrosion and maintains its strength. In the aerospace sector, its high-temperature stability and resistance to thermal fatigue make it suitable for various jet engine components, such as igniter systems, combustion can liners, and turbine seals. Its consistent performance ensures safety and efficiency in these critical applications.

Working with Alloy 601: Fabrication and Sourcing

While the performance of Inconel 601 is impressive, its successful implementation depends on proper fabrication techniques and sourcing from a reputable supplier. For machine shops and precision engineering firms, understanding how to work with this superior alloy is essential.

Machinability and Welding Considerations

Like most nickel-based alloys, Alloy 601 is prone to work-hardening. This means it requires a different approach than standard carbon steels. Machining should be done with powerful machines, sharp tools, and slow, steady speeds to avoid generating excessive heat and hardening the workpiece. For joining, the material is readily weldable using standard processes like Gas Tungsten Arc Welding (GTAW/TIG) and Gas Metal Arc Welding (GMAW/MIG). Using a matching filler metal is crucial to ensure the weld joint retains the corrosion resistance and mechanical properties of the base metal.

Available Forms and Specifications

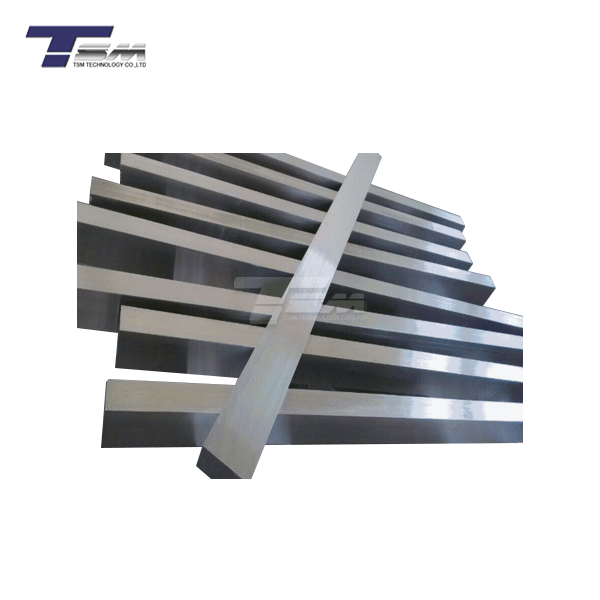

To meet the diverse needs of global industries, Inconel 601 is supplied in a variety of forms. A reliable stockist can provide the material you need to your exact specifications. Common forms include:

- Plate and Sheet (ASTM B168)

- Bar and Rod (ASTM B166)

- Pipe and Tube (ASTM B167, B775)

- Wire (ASTM B166)

- Forgings

Ensuring the material conforms to international standards like ASTM, ASME, and ISO is the first step in guaranteeing quality.

The Importance of a Quality Supplier

The ultimate performance of a component made from Alloy 601 is directly tied to the quality of the raw material. A superior alloy supplier does more than just sell metal; they provide assurance. This comes from a strict quality control and inspection system where every product is verified by professional inspectors. Full material traceability, certified test reports, and expert guidance ensure that the material you receive has the precise chemical composition and mechanical properties required for your application to perform flawlessly under pressure.

Conclusion

Inconel 601 stands as a testament to metallurgical innovation, offering a robust and reliable solution for high-temperature, corrosive environments. Its unparalleled resistance to oxidation, combined with its enduring mechanical strength and versatility in fabrication, solidifies its place as a critical material in heat treatment, chemical processing, power generation, and aerospace. For engineers and manufacturers facing extreme operational challenges, this nickel-chromium alloy provides not just a component, but also peace of mind. Choosing the right material is the first step, and partnering with a knowledgeable supplier ensures that its full potential is realized, leading to safer, more efficient, and longer-lasting systems.

FAQs

What is the main difference between Inconel 601 and 625?

Inconel 601 excels in high-temperature oxidation resistance, while Inconel 625 offers superior strength and corrosion resistance in diverse environments due to added molybdenum and niobium.

What is the maximum service temperature for Alloy 601?

Alloy 601 can be used for continuous service in oxidizing atmospheres up to approximately 1250°C (2282°F). Its ability to form a protective, adherent oxide scale ensures it maintains its integrity even under harsh thermal cycling at these temperatures.

Is Inconel 601 difficult to machine?

It is more challenging to machine than standard steels due to its tendency to work-harden rapidly. Success requires using powerful, rigid machine tools, operating at lower cutting speeds, maintaining a constant feed rate, and using appropriate coolants. With the right setup and experience, it can be machined to precise tolerances.

Choose the Premier Inconel 601 Supplier | TSM TECHNOLOGY

At TSM Technology, we are a leading manufacturer and supplier dedicated to providing superior nickel alloys like Inconel 601. With an international trading journey that began in 2011, our 14 years of evolution have built a reputation for innovation, reliability, and quality. Our strict quality control system, managed by professional inspectors, ensures every product meets the highest standards. As a factory and trusted partner, we provide various forms of Alloy 601 to serve the precision engineering industry globally. For inquiries or to receive a quote, contact us at info@tsmnialloy.com.

References

ASM Handbook, Volume 13B: Corrosion: Materials. ASM International, 2005.

Special Metals Corporation, Publication No. SMC-027: INCONEL alloy 601. 2008.

Davis, J.R., ed. Heat-Resistant Materials. ASM International, 1997.

High-Performance Alloys for the Chemical Process Industry. Nickel Institute, Publication No. 11025.

Lai, G.Y. High-Temperature Corrosion and Materials Applications. ASM International, 2007.

ASTM B168-19: Standard Specification for Nickel-Chromium-Iron Alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, N06045, and N06696) and Nickel-Chromium-Cobalt-Molybdenum Alloy (UNS N06617) Plate, Sheet, and Strip. ASTM International, 2019.

Learn about our latest products and discounts through SMS or email