- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Incoloy 825 Sheet Chemical Composition and Mechanical Properties

Incoloy 825 sheet is a high-performance nickel-iron-chromium alloy known for its exceptional corrosion resistance and mechanical strength. This versatile material offers excellent resistance to both oxidizing and reducing environments, making it ideal for various industrial applications. Understanding the chemical composition and mechanical properties of Incoloy 825 sheet is crucial for engineers and manufacturers seeking to leverage its unique characteristics in demanding environments. In this comprehensive guide, we'll explore the key elements that make up this remarkable alloy and delve into its impressive mechanical capabilities.

Chemical Composition of Incoloy 825 Sheet

Primary Elements and Their Contributions

Incoloy 825 sheet derives its outstanding properties from a carefully balanced combination of elements. The primary components include nickel (38-46%), iron (22% minimum), and chromium (19.5-23.5%). Nickel provides excellent resistance to chloride stress corrosion cracking and imparts stability to the alloy's austenitic structure. Iron serves as a cost-effective base metal while contributing to the alloy's strength. Chromium forms a protective oxide layer, enhancing the material's resistance to various corrosive media.

Secondary Elements for Enhanced Performance

In addition to the primary elements, Incoloy 825 sheet contains several secondary elements that further enhance its properties. These include molybdenum (2.5-3.5%), which improves resistance to pitting and crevice corrosion, particularly in chloride-containing environments. Copper (1.5-3%) is added to boost resistance to reducing acids, such as sulfuric acid. Titanium (0.6-1.2%) helps prevent sensitization and improves resistance to intergranular corrosion.

Trace Elements and Their Impact

Trace elements in Incoloy 825 sheet, while present in small quantities, play crucial roles in fine-tuning the alloy's properties. Carbon content is limited to a maximum of 0.05% to minimize carbide precipitation and maintain corrosion resistance. Small amounts of manganese (up to 1%) and silicon (up to 0.5%) are included to aid in deoxidation during the melting process and improve workability. Aluminum (0.2% maximum) contributes to oxidation resistance at elevated temperatures.

Mechanical Properties of Incoloy 825 Plate

Tensile Strength and Yield Strength

Incoloy 825 plate exhibits impressive mechanical strength, making it suitable for applications requiring high structural integrity. The typical minimum tensile strength of annealed Incoloy 825 plate ranges from 690 to 860 MPa (100 to 125 ksi), depending on the thickness and processing conditions. The yield strength (0.2% offset) is generally between 310 and 450 MPa (45 to 65 ksi). These values ensure that Incoloy 825 plate can withstand significant loads without permanent deformation.

Elongation and Hardness

The ductility of Incoloy 825 plate is demonstrated by its excellent elongation properties. Typical elongation values range from 30% to 45% in a 2-inch (50.8 mm) gauge length, indicating the material's ability to deform plastically before fracture. This characteristic is particularly valuable in fabrication processes and applications involving thermal cycling. The hardness of annealed Incoloy 825 plate typically falls between 140 and 200 Brinell, providing a good balance between strength and machinability.

Impact Strength and Fracture Toughness

Incoloy 825 plate demonstrates superior toughness across a wide temperature range. The Charpy V-notch impact strength at room temperature often exceeds 160 J (120 ft-lbs), with minimal ductile-to-brittle transition even at cryogenic temperatures. This high impact resistance makes Incoloy 825 plate an excellent choice for applications subject to dynamic loading or sudden impacts. The alloy's fracture toughness, a measure of its ability to resist crack propagation, is also noteworthy, contributing to its reliability in critical components.

Applications and Benefits of Incoloy 825 Sheet

Chemical Processing Industry

In the chemical processing industry, Incoloy 825 sheet is widely utilized in systems that handle aggressive chemicals and extreme environments. Its balanced composition of nickel, iron, and chromium provides exceptional protection against both oxidizing and reducing acids, including sulfuric and phosphoric acids. This makes it a preferred material for acid production plants, heat exchangers, evaporators, and scrubbers. Additionally, its remarkable resistance to chloride-induced stress corrosion cracking ensures reliable performance in seawater-based and high-salinity operations, extending equipment lifespan and reducing maintenance costs.

Oil and Gas Sector

Incoloy 825 sheet serves a vital role in the oil and gas sector, particularly in environments containing hydrogen sulfide, carbon dioxide, and chlorides. It is often used in tubing, separators, and pipelines for sour gas wells, where conventional materials might fail due to corrosion or stress cracking. The alloy's robust mechanical strength under high pressure and temperature ensures structural integrity during drilling and production. Its long-term durability minimizes downtime and replacement needs, contributing to improved operational safety and cost efficiency in harsh offshore and onshore environments.

Nuclear Power Generation

Within nuclear power generation, Incoloy 825 sheet is chosen for its outstanding resistance to radiation-induced corrosion and thermal degradation. It performs exceptionally well in high-temperature water and steam environments, maintaining stability and mechanical strength over extended service periods. Components such as heat exchangers, reactor cores, and fuel reprocessing systems benefit from its superior resistance to pitting and intergranular corrosion. The alloy's reliability under both oxidizing and reducing conditions ensures safe and efficient operation of nuclear systems, making it a trusted material for critical and safety-sensitive nuclear infrastructure.

Conclusion

Incoloy 825 sheet and Incoloy 825 plate offer a remarkable combination of chemical composition and mechanical properties that make them invaluable in numerous industrial applications. Their exceptional corrosion resistance, coupled with impressive strength and ductility, positions them as top choices for engineers tackling challenging environments. As industries continue to push the boundaries of material performance, Incoloy 825 remains at the forefront, providing reliable solutions for the most demanding applications.

FAQs

What makes Incoloy 825 sheet resistant to corrosion?

Its high nickel and chromium content forms a protective oxide layer, while molybdenum enhances pitting resistance.

Can an Incoloy 825 plate be welded easily?

Yes, it has excellent weldability due to its stabilized composition, which prevents sensitization.

How does Incoloy 825 perform in high-temperature applications?

It maintains good strength and corrosion resistance up to about 540°C (1000°F).

Is Incoloy 825 suitable for cryogenic use?

Yes, it retains its toughness at low temperatures, making it suitable for cryogenic applications.

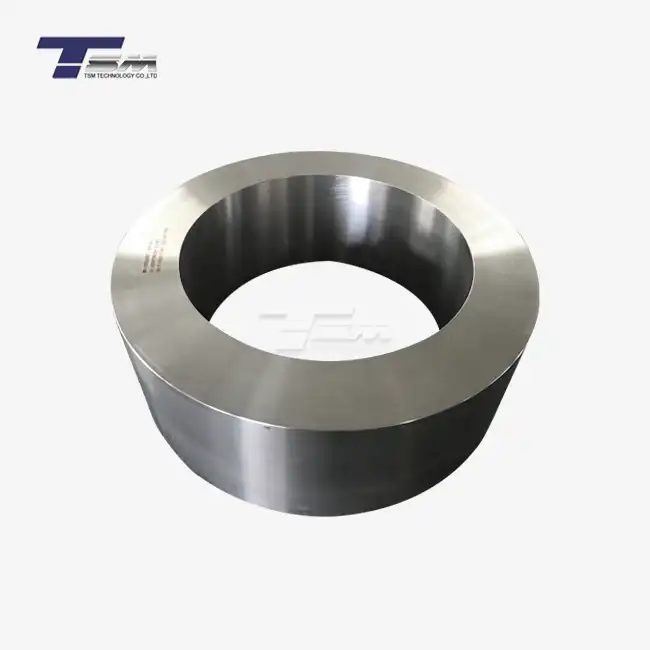

Why Choose TSM TECHNOLOGY for Your Incoloy 825 Sheet Needs?

TSM TECHNOLOGY stands out as a premier Incoloy 825 sheet manufacturer and supplier, offering superior quality and unmatched expertise. With over 14 years of experience in the industry, we provide precision-engineered Incoloy 825 products tailored to your specific requirements. Our state-of-the-art manufacturing facilities and rigorous quality control ensure consistency and reliability in every sheet and plate we produce. For inquiries or to discuss your Incoloy 825 needs, contact our experts at info@tsmnialloy.com. Choose TSM TECHNOLOGY for excellence in Incoloy 825 solutions.

References

Special Metals Corporation. "Incoloy alloy 825." Technical Bulletin, 2013.

ASM International. "Properties and Selection: Irons, Steels, and High-Performance Alloys." ASM Handbook, Volume 1, 1990.

NACE International. "Corrosion of Nickel-Base Alloys." NACE International Publication 1G194, 2018.

American Society for Testing and Materials. "ASTM B424 - Standard Specification for Ni-Fe-Cr-Mo-Cu Alloy (UNS N08825 and UNS N08221) Plate, Sheet, and Strip." ASTM International, 2020.

Metals and Materials International. "Effect of Heat Treatment on the Microstructure and Mechanical Properties of Incoloy 825 Alloy." Vol. 24, Issue 5, 2018.

Journal of Materials Engineering and Performance. "Corrosion Behavior of Incoloy 825 in Simulated Nuclear Waste Solutions." Vol. 29, Issue 3, 2020.

Learn about our latest products and discounts through SMS or email