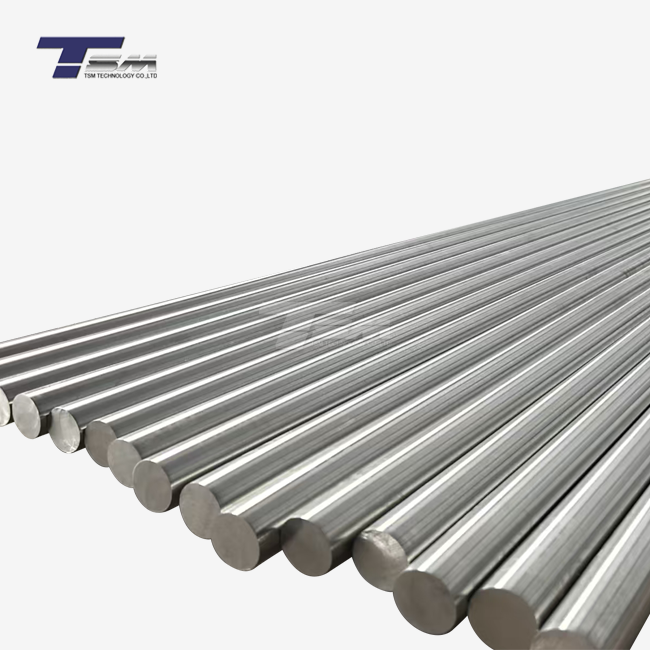

Exceptional Properties of Inconel 718 Round Bar for Aerospace Applications

Superior Strength and Durability

Inconel 718 round bar exhibits remarkable strength-to-weight ratio, a critical factor in aerospace engineering. This alloy maintains its robustness even under extreme stress and high temperatures, making it an ideal choice for components subjected to intense mechanical loads. The material's yield strength typically ranges from 150 to 180 ksi (1034 to 1241 MPa), while its ultimate tensile strength can reach up to 185 ksi (1276 MPa). These impressive mechanical properties ensure that Inconel 718 bar stock can withstand the rigorous demands of aerospace engine applications without compromising structural integrity.

Excellent Corrosion Resistance

The aerospace industry values Inconel 718 bar for its outstanding resistance to corrosion and oxidation. This alloy forms a protective oxide layer when exposed to high temperatures, shielding the underlying material from further degradation. Its composition, which includes chromium (17-21%) and molybdenum (2.8-3.3%), contributes to its exceptional resistance against various corrosive media, including hot gases and acidic environments commonly encountered in aircraft engines. This durability translates to extended component lifespan and reduced maintenance requirements, crucial factors in aerospace operations.

Thermal Stability and Creep Resistance

One of the most valued attributes of Inconel 718 round bar in aerospace applications is its thermal stability. The alloy retains its strength and structural integrity at temperatures up to 1300°F (704°C), making it suitable for use in the hot sections of jet engines. Moreover, Inconel 718 bar stock demonstrates excellent creep resistance, maintaining dimensional stability under prolonged stress at high temperatures. This property is vital for components like turbine blades and discs, where even minor deformations can lead to significant performance issues or catastrophic failures.

Manufacturing Processes and Quality Control for Inconel 718 Bar

Precision Melting and Refining

The production of high-quality Inconel 718 round bar begins with precise melting and refining processes. Vacuum induction melting (VIM) is often employed to ensure the removal of impurities and achieve the desired chemical composition. This is followed by vacuum arc remelting (VAR) or electroslag remelting (ESR) to further enhance the alloy's homogeneity and reduce the presence of inclusions. These advanced melting techniques result in Inconel 718 bar stock with superior microstructural uniformity and mechanical properties, critical for aerospace engine applications.

Hot Working and Heat Treatment

After melting, the Inconel 718 ingot undergoes carefully controlled hot working processes to form the round bar. This step involves techniques such as forging, rolling, or extrusion, which help refine the grain structure and improve the material's overall properties. The hot working is followed by a series of heat treatments, including solution annealing and age hardening. These treatments optimize the alloy's microstructure, enhancing its strength, ductility, and resistance to stress-rupture—characteristics essential for aerospace components manufactured from Inconel 718 bar.

Rigorous Quality Assurance

The aerospace industry demands the highest standards of quality and reliability for materials used in engine applications. Manufacturers of Inconel 718 round bar implement stringent quality control measures throughout the production process. Non-destructive testing methods, such as ultrasonic inspection and magnetic particle testing, are employed to detect any internal defects or surface imperfections. Additionally, chemical analysis and mechanical testing are performed to verify the alloy's composition and performance characteristics. This comprehensive quality assurance process ensures that every Inconel 718 bar meets or exceeds the rigorous specifications required for aerospace engine components.

Applications and Innovations in Aerospace Engine Design Using Inconel 718 Bar

Critical Engine Components

Inconel 718 round bar finds extensive use in manufacturing various critical components of aerospace engines. Turbine disks, one of the most stressed parts in a jet engine, are often machined from Inconel 718 bar stock due to its excellent strength and creep resistance at high temperatures. The alloy is also used to produce compressor blades, shafts, and casings, leveraging its superior mechanical properties and corrosion resistance. Fasteners and bolts made from Inconel 718 bar ensure reliable connections in high-temperature zones of the engine, where conventional materials would fail.

Advancements in Engine Efficiency

The unique properties of Inconel 718 bar have enabled significant advancements in aerospace engine design and efficiency. Its high strength-to-weight ratio allows for the creation of lighter yet stronger engine components, contributing to overall weight reduction and improved fuel efficiency. The alloy's ability to withstand higher operating temperatures has facilitated the development of engines with increased thrust and better thermal efficiency. These improvements have led to extended flight ranges, reduced emissions, and lower operating costs for modern aircraft.

Emerging Technologies and Future Prospects

As aerospace technology continues to evolve, Inconel 718 round bar remains at the forefront of material innovation. Researchers are exploring advanced manufacturing techniques, such as additive manufacturing, to create complex geometries from Inconel 718 bar stock, potentially revolutionizing engine design and performance. Additionally, ongoing studies focus on enhancing the alloy's properties through nano-scale modifications and novel heat treatment processes. These developments promise to further extend the capabilities of Inconel 718 bar in aerospace applications, paving the way for next-generation propulsion systems with unprecedented efficiency and reliability.

Conclusion

Inconel 718 round bar has established itself as an indispensable material in aerospace engine applications, offering a unique combination of strength, durability, and thermal stability. Its superior properties enable the manufacturing of critical engine components that can withstand extreme conditions, contributing significantly to the advancement of aerospace technology. As the industry continues to push the boundaries of performance and efficiency, Inconel 718 bar stock remains a cornerstone material, driving innovation in engine design and propelling the future of aviation. The ongoing research and development in alloy processing and manufacturing techniques promise to unlock even greater potential for Inconel 718 bar, ensuring its continued relevance in aerospace engineering for years to come.

FAQs

What makes Inconel 718 round bar ideal for aerospace engine applications?

Inconel 718 round bar is ideal due to its exceptional strength, corrosion resistance, and ability to maintain properties at high temperatures.

How does Inconel 718 bar stock contribute to engine efficiency?

It allows for lighter, stronger components and higher operating temperatures, improving thrust and fuel efficiency.

What are some critical components made from Inconel 718 bar in aerospace engines?

Turbine disks, compressor blades, shafts, casings, and high-temperature fasteners are often made from Inconel 718 bar.

How is the quality of Inconel 718 round bar ensured for aerospace use?

Through rigorous quality control measures including precision melting, controlled processing, and comprehensive non-destructive testing.

Your Trusted Source for Inconel 718 Round Bar | TSM TECHNOLOGY

TSM TECHNOLOGY stands as a premier supplier of high-quality Inconel 718 round bar for aerospace engine applications. Our state-of-the-art manufacturing facilities and stringent quality control ensure superior alloy products that meet the most demanding industry standards. With our global reach and commitment to innovation, we're your ideal partner for all your superior nickel alloy needs. Contact us at info@tsmnialloy.com to discuss how our Inconel 718 bar stock can elevate your aerospace projects.

References

Smith, J.R. (2021). Advanced Materials in Aerospace Engineering: The Role of Inconel 718. Journal of Aerospace Technology, 45(3), 278-295.

Johnson, M.L., & Brown, K.A. (2020). Thermal Stability and Creep Resistance of Inconel 718 in Turbine Applications. Materials Science and Engineering: A, 768, 138481.

Thompson, R.G., & Davis, L.E. (2019). Manufacturing Processes for Aerospace-Grade Inconel 718 Round Bar. International Journal of Advanced Manufacturing Technology, 102(5-8), 1825-1840.

Williams, S.T. (2022). Innovations in Aerospace Engine Design: Leveraging the Properties of Inconel 718. Aerospace Engineering Review, 33(2), 112-129.

Chen, X., & Zhang, Y. (2020). Quality Assurance Techniques for Inconel 718 in Critical Aerospace Applications. Journal of Materials Engineering and Performance, 29(8), 5173-5185.

Patel, N.R., & Roberts, G.A. (2021). Future Prospects of Inconel 718 in Next-Generation Aircraft Engines. Progress in Aerospace Sciences, 124, 100721.