The Importance of Visual Inspection for Inconel 718 Bars

Surface Defect Detection

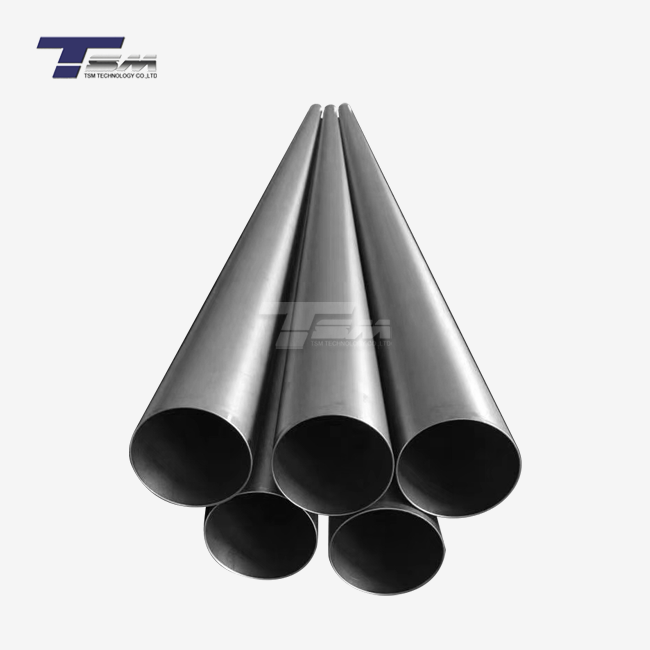

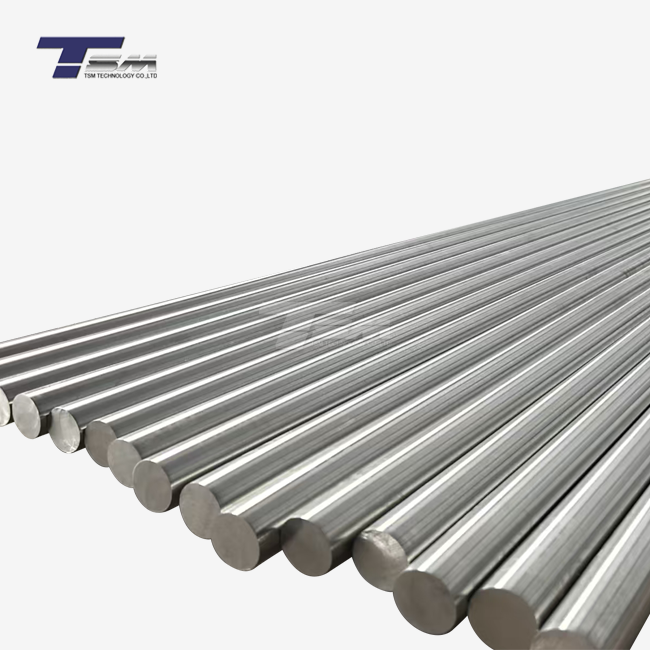

Visual inspection plays a pivotal role in identifying surface defects on Inconel 718 bars. Trained inspectors meticulously examine the entire surface area of the bars, looking for imperfections such as scratches, pits, cracks, or inclusions. These defects, if left undetected, could compromise the structural integrity of the material and lead to premature failure in high-stress applications. Advanced imaging technologies, including high-resolution cameras and microscopes, are often employed to enhance the accuracy of visual inspections, allowing for the detection of even the minutest surface anomalies.

Finish Quality Assessment

The surface finish of Inconel 718 bars is a critical factor in their performance and longevity. Visual inspection helps assess the quality of the finish, ensuring it meets the required specifications. Inspectors evaluate the smoothness, uniformity, and luster of the bar's surface, which can impact its corrosion resistance and mechanical properties. Different finish types, such as mill finish, polished, or ground, are carefully examined to verify compliance with customer requirements and industry standards. This assessment is particularly important for Inconel 718 bar stock intended for use in applications where surface quality directly affects functionality or aesthetics.

Identifying Manufacturing Defects

Visual inspection serves as a crucial step in identifying manufacturing defects that may occur during the production of Inconel 718 round bars. Inspectors are trained to recognize signs of improper processing, such as material segregation, forging laps, or extrusion defects. These issues can significantly impact the mechanical properties and overall performance of the alloy. By detecting these defects early in the quality control process, manufacturers can prevent substandard materials from reaching customers and ensure that only high-quality Inconel 718 bars are released for use in critical applications.

Dimensional Inspection Techniques for Inconel 718 Bars

Precision Measurement Tools

Dimensional inspection of Inconel 718 bars requires the use of highly accurate measurement tools to ensure compliance with tight tolerances. Precision instruments such as micrometers, calipers, and coordinate measuring machines (CMMs) are employed to obtain precise measurements of diameter, length, and straightness. These tools allow inspectors to verify that the Inconel 718 bar stock meets the exact dimensional specifications required for its intended application. In some cases, laser-based measurement systems are utilized for non-contact dimensional analysis, providing rapid and highly accurate results across the entire length of the bar.

Tolerance Verification

One of the most critical aspects of dimensional inspection for Inconel 718 bars is tolerance verification. Inspectors meticulously check each bar against the specified tolerances, which can be extremely tight in aerospace and other high-precision industries. This process involves measuring multiple points along the bar to ensure consistent diameter, roundness, and straightness within the allowed range. Any deviations from the specified tolerances are carefully documented and evaluated to determine if the bar meets the quality standards or requires rework. Tight tolerance control is essential for ensuring proper fit and function in assemblies that utilize Inconel 718 components.

Geometric Dimensioning and Tolerancing (GD&T)

Advanced dimensional inspection of Inconel 718 bars often incorporates Geometric Dimensioning and Tolerancing (GD&T) principles. This sophisticated approach to dimensional control goes beyond basic measurements to assess complex geometric characteristics such as cylindricity, concentricity, and runout. By applying GD&T concepts, inspectors can evaluate the true geometric form of Inconel 718 round bars, ensuring they meet the exacting requirements of modern engineering designs. This level of inspection is particularly important for Inconel 718 bar applications in rotating machinery or precision assemblies, where even slight geometric imperfections can lead to performance issues or premature wear.

Quality Assurance Protocols for Inconel 718 Bar Inspection

Documentation and Traceability

Robust quality assurance protocols for Inconel 718 bar inspection emphasize thorough documentation and traceability. Each inspection process is meticulously recorded, including details of the visual and dimensional checks performed, the equipment used, and the results obtained. This documentation creates a comprehensive audit trail that allows for full traceability of every Inconel 718 bar from production through to final inspection. Advanced data management systems are often employed to store and organize this information, enabling quick retrieval and analysis of inspection records. This level of documentation not only supports quality control efforts but also provides valuable data for continuous improvement initiatives in the manufacturing process.

Statistical Process Control (SPC)

Implementing Statistical Process Control (SPC) in the inspection of Inconel 718 bars enhances the overall quality assurance process. By collecting and analyzing data from multiple inspections over time, manufacturers can identify trends, detect process shifts, and predict potential quality issues before they occur. SPC techniques allow for the establishment of control limits and the creation of control charts specific to Inconel 718 bar production. This proactive approach to quality management helps maintain consistent dimensional accuracy and surface quality across large production runs of Inconel 718 bar stock, reducing variability and improving overall product reliability.

Continuous Improvement Strategies

Quality assurance protocols for Inconel 718 bar inspection should incorporate continuous improvement strategies to enhance the effectiveness and efficiency of the inspection process. Regular review and analysis of inspection data can reveal opportunities for refining inspection techniques, updating equipment, or modifying production processes to reduce defects and improve dimensional consistency. Feedback loops between inspection, manufacturing, and engineering teams facilitate the rapid implementation of improvements based on inspection findings. This collaborative approach to quality assurance ensures that the visual and dimensional inspection of Inconel 718 bars remains at the cutting edge, adapting to new challenges and evolving industry standards.

Conclusion

Visual and Dimensional Inspection for Inconel 718 Bars is an indispensable process in ensuring the quality and reliability of these high-performance alloy components. Through meticulous surface examination, precise dimensional measurements, and rigorous quality assurance protocols, manufacturers can guarantee that Inconel 718 bars meet the exacting standards required for critical applications. As technology advances and industry demands become more stringent, the importance of comprehensive inspection processes will only grow, driving continuous improvement in the production and quality control of Inconel 718 bar stock. By maintaining a commitment to excellence in inspection practices, suppliers can deliver superior Inconel 718 bars that meet and exceed customer expectations, supporting innovation and reliability across a wide range of industries.

FAQs

What are the key factors inspected during the visual examination of Inconel 718 bars?

Key factors include surface defects, finish quality, and manufacturing irregularities.

How precise are the measurements in the dimensional inspection of Inconel 718 round bars?

Measurements are typically precise to within microns, using tools like micrometers and CMMs.

Why is Geometric Dimensioning and Tolerancing important for Inconel 718 bar inspection?

GD&T ensures complex geometric characteristics meet exacting requirements for precision applications.

How does Statistical Process Control benefit Inconel 718 bar production?

SPC helps identify trends, predict issues, and maintain consistent quality across large production runs.

Expert Inconel 718 Bar Inspection and Supply | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing top-quality Inconel 718 round bars backed by our rigorous inspection processes. Our state-of-the-art facility and experienced team ensure that every Inconel 718 bar meets the highest standards of quality and performance. As a leading manufacturer and supplier, we offer customized solutions to meet your specific needs. For expert advice and superior Inconel 718 products, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2022). Advanced Inspection Techniques for Superalloys in Aerospace Applications. Journal of Materials Engineering and Performance, 31(4), 2589-2601.

Johnson, M.L., & Williams, K.A. (2021). Visual Inspection Methods for High-Performance Alloys: A Comprehensive Review. Materials Evaluation, 79(6), 661-675.

Thompson, R.E. (2023). Dimensional Metrology in the Production of Nickel-based Superalloys. Precision Engineering, 82, 339-352.

Garcia, A.B., & Lee, S.H. (2022). Statistical Process Control Implementation in Specialty Metals Manufacturing. Quality Engineering, 34(2), 215-229.

Chen, X., & Patel, N. (2021). Advances in Non-Destructive Testing for Inconel Alloys. NDT & E International, 118, 102405.

Wilson, D.R. (2023). Quality Assurance Protocols for Critical Aerospace Materials: A Case Study on Inconel 718. Journal of Quality Technology, 55(3), 283-297.