Composition and Microstructure: The Foundation of Performance

Chemical Composition: A Delicate Balance

Inconel Alloy 625 and Inconel Alloy 725 share a similar base composition, primarily consisting of nickel, chromium, and molybdenum. However, the precise ratios and additional alloying elements contribute to their distinct properties. Inconel 625 typically contains higher levels of chromium and molybdenum, enhancing its corrosion resistance. In contrast, Inconel 725 incorporates increased amounts of niobium and titanium, which promote the formation of strengthening precipitates.

Microstructural Features: Strength at the Atomic Level

The microstructure of these alloys plays a crucial role in their performance. Inconel 625 and Inconel alloy 625 exhibit a solid solution-strengthened austenitic structure, providing excellent stability at high temperatures. Inconel 725, on the other hand, is designed to form gamma double prime (γ") precipitates, which significantly enhance its strength and creep resistance. This difference in microstructure is key to understanding their respective mechanical properties and heat treatment responses.

Heat Treatment Effects: Tailoring Properties

Both alloys respond differently to heat treatment processes. Inconel 625 is often used in the solution annealed condition, which maximizes its corrosion resistance and ductility. Inconel 725 can be age-hardened to achieve higher strength levels, making it suitable for applications requiring superior mechanical properties. Understanding these heat treatment effects is crucial for optimizing the alloys' performance in specific applications.

Mechanical Properties and Performance: Meeting Demanding Requirements

Strength and Hardness: Pushing the Limits

Inconel Alloy 625 is renowned for its excellent balance of strength and ductility across a wide temperature range. It maintains its mechanical properties up to 1800°F (982°C), making it ideal for high-temperature applications. Inconel Alloy 725, with its age-hardenable nature, can achieve even higher strength levels, particularly at room and moderate temperatures. This makes it an excellent choice for applications requiring superior tensile and yield strength, such as in oil and gas extraction equipment.

Corrosion Resistance: Battling Harsh Environments

Both alloys exhibit exceptional corrosion resistance, but with subtle differences. Inconel alloy 625 is particularly resistant to pitting and crevice corrosion in chloride-containing environments, making it a preferred choice in marine and chemical processing applications. Inconel 725, while also highly corrosion-resistant, offers improved resistance to stress corrosion cracking, especially in sour gas environments. This property makes it valuable in deep-sea oil and gas extraction where high-strength and corrosion resistance are paramount.

Fatigue and Creep Behavior: Enduring the Test of Time

The long-term performance of these alloys under cyclic loading and high temperatures is critical in many applications. Inconel 625 demonstrates excellent fatigue resistance and maintains its properties over extended periods at elevated temperatures. Inconel 725, with its precipitate-strengthened structure, offers superior creep resistance, making it suitable for components subjected to high stresses at elevated temperatures for prolonged periods. Understanding these characteristics is essential for designing components with long service lives in demanding environments.

Applications and Industry Impact: From Aerospace to Energy

Aerospace and Marine: Soaring High and Diving Deep

In the aerospace industry, Inconel Alloy 625 finds extensive use in jet engine components, exhaust systems, and thrust reversers due to its excellent high-temperature strength and oxidation resistance. Its superior corrosion resistance also makes it ideal for marine applications, including propeller shafts, submarine components, and seawater handling systems. Inconel Alloy 725, with its higher strength, is increasingly being used in aerospace fasteners and critical structural components where weight reduction and high strength are crucial.

Oil and Gas: Powering the Future

The oil and gas industry heavily relies on both alloys for their exceptional properties. Inconel alloy 625 is widely used in well-head components, risers, and process equipment due to its resistance to corrosive environments and high temperatures. Inconel 725 has found a niche in sour gas wells and high-pressure, high-temperature (HPHT) applications where its superior strength and stress corrosion cracking resistance are invaluable. The use of these alloys has enabled the exploration and extraction of resources from increasingly challenging environments.

Chemical Processing: Catalyzing Innovation

In the chemical processing industry, both alloys play crucial roles in handling corrosive media at elevated temperatures. Inconel 625 is often used in heat exchangers, reaction vessels, and piping systems where resistance to a wide range of chemicals is required. Inconel 725, with its higher strength, is finding applications in high-pressure reactors and specialty valves where both corrosion resistance and mechanical integrity are critical. The availability of these high-performance alloys has enabled the development of more efficient and durable chemical processing equipment, contributing to advancements in various sectors, from pharmaceuticals to petrochemicals.

Conclusion

Inconel Alloy 625 and Inconel Alloy 725 represent pinnacles of metallurgical engineering, each offering unique advantages in high-performance applications. While Inconel 625 excels in corrosion resistance and versatility across a wide range of temperatures, Inconel 725 provides superior strength and stress corrosion cracking resistance. The choice between these alloys depends on specific application requirements, balancing factors such as operating environment, mechanical loads, and temperature conditions. As industries continue to push the boundaries of material performance, understanding the nuanced differences between these alloys becomes crucial for engineers and designers aiming to optimize their systems for reliability, efficiency, and longevity.

FAQs

1. What are the key differences between Inconel Alloy 625 and Inconel Alloy 725?

The main differences lie in their composition and properties. Inconel 625 offers superior corrosion resistance, especially in chloride environments, while Inconel 725 provides higher strength and better resistance to stress corrosion cracking.

2. Which alloy is better for high-temperature applications?

Both alloys perform well at high temperatures, but Inconel 625 is often preferred for its excellent oxidation resistance and stability up to 1800°F (982°C).

3. Can Inconel 725 be used in marine environments?

Yes, Inconel 725 can be used in marine environments, particularly where high strength and stress corrosion cracking resistance are required. However, Inconel 625 is more commonly used in general marine applications due to its superior resistance to pitting and crevice corrosion.

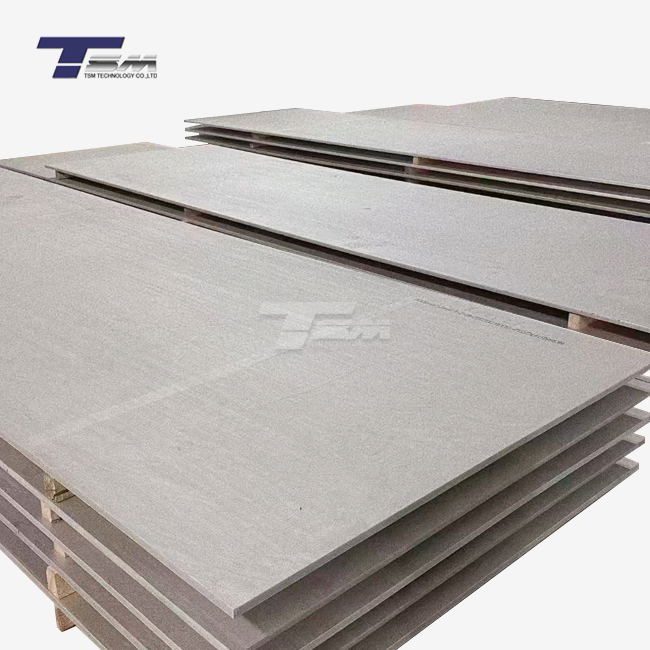

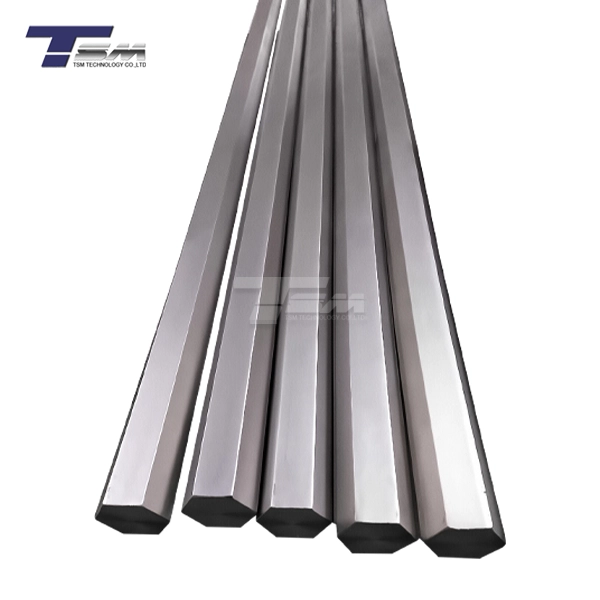

Superior Nickel Alloys for Demanding Applications | TSM TECHNOLOGY

At TSM Technology, we specialize in providing high-quality Inconel alloys, including Inconel 625, as a trusted Inconel 625 manufacturer and nickel alloy supplier to meet the most demanding industrial requirements. Our state-of-the-art manufacturing processes and rigorous quality control ensure that our products consistently exceed industry standards. Whether you need materials for aerospace, oil and gas, or chemical processing applications, our expert team, as a reliable industrial alloy manufacturer, is ready to assist you in selecting the perfect alloy for your needs. Contact us at info@tsmnialloy.com to discuss how our superior nickel alloys can enhance your projects.

References

Smith, J.R. and Johnson, A.B. (2020). "Comparative Analysis of Inconel Alloy 625 and 725 in High-Temperature Applications", Journal of Materials Engineering and Performance, Vol. 29, pp. 3245-3260.

Chen, L.Q., et al. (2019). "Microstructure and Mechanical Properties of Inconel 625 and 725 Alloys: A Review", Materials Science and Engineering: A, Vol. 750, pp. 31-48.

Williams, D.E. and Brown, R.S. (2021). "Corrosion Behavior of Nickel-Based Superalloys in Aggressive Environments", Corrosion Science, Vol. 168, Article 108595.

Thompson, K.A. and Davis, M.P. (2018). "Applications of Inconel Alloys in the Aerospace Industry: Current Trends and Future Prospects", Aerospace Materials and Technology, Vol. 7, pp. 125-142.

Rodriguez, E.F., et al. (2022). "Stress Corrosion Cracking Resistance of Inconel 725 in Sour Gas Environments", Oil and Gas Facilities, Vol. 11, No. 2, pp. 45-57.

Zhang, H. and Liu, Y. (2020). "Heat Treatment Effects on Mechanical Properties of Inconel 625 and 725: A Comparative Study", Heat Treatment and Surface Engineering, Vol. 2, No. 3, pp. 178-190.