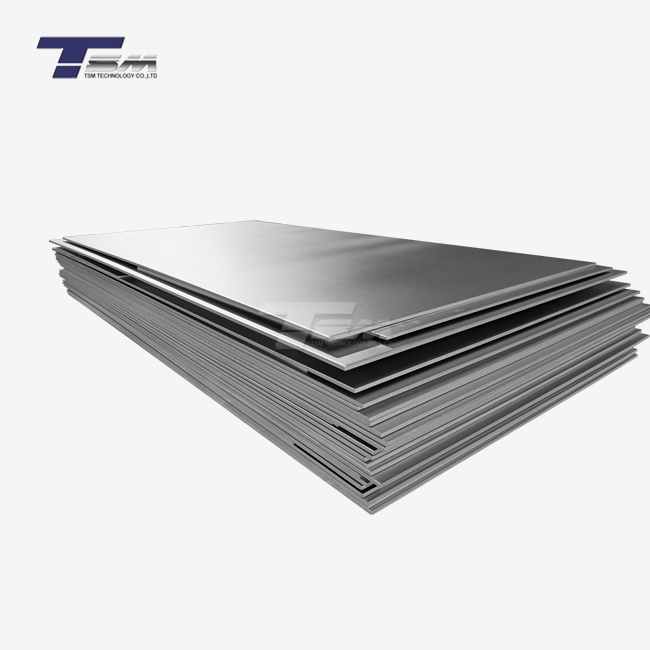

Properties and Advantages of Incoloy 825 Sheet for Heat Exchangers

Superior Corrosion Resistance

Incoloy 825 sheet boasts remarkable resistance to a wide range of corrosive environments. Its high nickel and chromium content forms a protective oxide layer, shielding the material from aggressive chemicals and acids. This property is particularly valuable in heat exchangers exposed to sulfuric acid, phosphoric acid, and other corrosive media. The alloy's resistance to pitting and crevice corrosion ensures longevity in applications where other materials might fail prematurely.

Excellent High-Temperature Performance

One of the standout features of Incoloy 825 plate is its ability to maintain mechanical properties at elevated temperatures. The alloy retains strength and ductility up to 540°C (1000°F), making it ideal for heat exchangers in high-temperature processes. This temperature stability prevents warping, distortion, and creep, ensuring consistent performance and tight tolerances over extended periods of operation.

Versatility in Fabrication

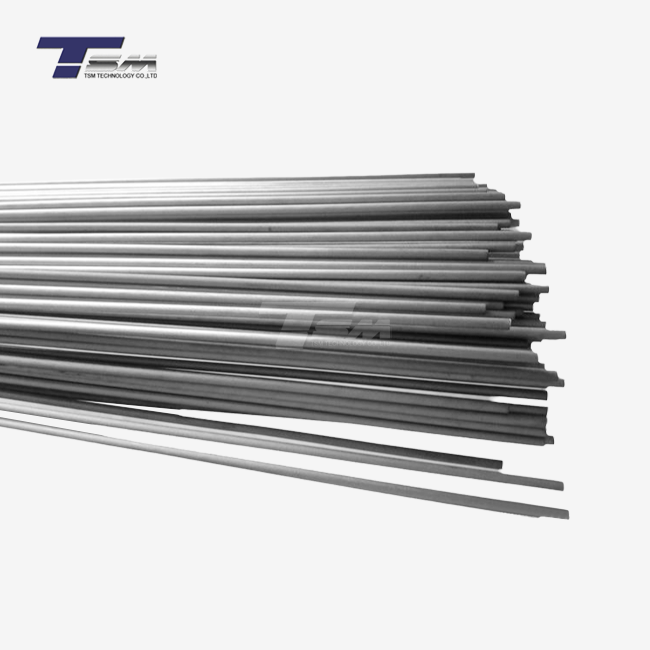

Incoloy 825 sheet offers excellent fabricability, allowing for the creation of complex heat exchanger designs. The material can be easily welded, formed, and machined, facilitating the production of intricate tube sheets, baffles, and headers. This versatility enables engineers to optimize heat transfer efficiency while maintaining the structural integrity required for demanding applications.

Applications of Incoloy 825 Sheet in Various Heat Exchanger Types

Shell and Tube Heat Exchangers

In shell and tube heat exchangers, Incoloy 825 sheet is frequently used for tube sheets and baffles. Its corrosion resistance protects against aggressive fluids on both the shell and tube sides, while its high-temperature strength ensures dimensional stability. The alloy's thermal conductivity, though not as high as copper's, provides efficient heat transfer in applications where corrosion resistance is paramount.

Plate Heat Exchangers

Incoloy 825 plate finds extensive use in gasket-sealed and welded plate heat exchangers. The material's ability to be formed into thin, corrugated sheets with precise patterns maximizes heat transfer surface area. Its resistance to stress corrosion cracking makes it suitable for handling a variety of process fluids, including seawater and chemical solutions, in compact, high-efficiency designs.

Air-Cooled Heat Exchangers

In air-cooled heat exchangers, particularly those used in petrochemical and power generation industries, Incoloy 825 sheet is utilized for fin-tube assemblies. The alloy's resistance to high-temperature oxidation and sulfidation protects against degradation in exhaust gas environments. Its thermal stability ensures consistent performance in cyclical temperature conditions typical of these applications.

Considerations for Implementing Incoloy 825 Sheet in Heat Exchanger Design

Material Selection Criteria

When considering Incoloy 825 sheet for heat exchanger applications, engineers must evaluate several factors. These include the specific corrosive agents present, operating temperatures, pressure requirements, and expected service life. While Incoloy 825 offers superior performance in many scenarios, it's essential to compare its properties with alternative materials to ensure optimal cost-effectiveness and performance for the given application.

Design Optimization

Leveraging the unique properties of Incoloy 825 plate requires thoughtful design optimization. Engineers should consider the alloy's thermal expansion characteristics, which differ from more common materials like carbon steel. Proper allowance for thermal expansion in the design phase can prevent stress-related issues during operation. Additionally, the material's superior corrosion resistance may allow for thinner walls in some applications, potentially reducing weight and material costs.

Fabrication and Quality Control

Successful implementation of Incoloy 825 sheet in heat exchangers demands strict adherence to fabrication best practices. Proper welding procedures, including appropriate filler metals and post-weld heat treatment, are crucial to maintaining the alloy's corrosion resistance. Rigorous quality control measures, such as non-destructive testing and material traceability, ensure the finished heat exchanger meets the demanding specifications required for critical applications.

Conclusion

Incoloy 825 sheet has established itself as a cornerstone material in the design and fabrication of high-temperature heat exchangers. Its exceptional corrosion resistance, coupled with impressive mechanical properties at elevated temperatures, makes it an ideal choice for demanding applications across various industries. As engineers continue to push the boundaries of heat exchanger performance and efficiency, Incoloy 825 remains at the forefront, enabling innovative designs that withstand increasingly harsh operating conditions. By carefully considering the material's properties and optimizing designs accordingly, manufacturers can leverage Incoloy 825 to create heat exchangers that offer superior longevity, reliability, and performance in even the most challenging environments.

FAQs

What makes Incoloy 825 sheet superior for high-temperature heat exchangers?

Incoloy 825 excels due to its exceptional corrosion resistance, high-temperature strength, and stability in aggressive environments. It maintains its properties at elevated temperatures, resists various forms of corrosion, and offers good fabricability.

How does Incoloy 825 compare to other materials in terms of cost-effectiveness?

While initially more expensive than some alternatives, Incoloy 825 often proves cost-effective in the long run due to its extended service life, reduced maintenance needs, and ability to operate in harsh conditions where other materials might fail prematurely.

Are there any specific considerations for welding Incoloy 825 sheet in heat exchanger fabrication?

Yes, proper welding procedures are crucial. Using appropriate filler metals, controlling heat input, and performing post-weld heat treatment when necessary are important to maintain the alloy's corrosion resistance and mechanical properties.

Experience the Incoloy 825 Sheet Advantage with TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing high-quality Incoloy 825 sheet and plate for demanding heat exchanger applications. Our expertise in nickel alloys, coupled with rigorous quality control and customization capabilities, ensures you receive materials that meet your exact specifications. With a global presence and over 14 years of industry experience, we're your trusted partner for superior alloy solutions. For inquiries or to discuss your Incoloy 825 needs, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2020). "Advanced Materials in High-Temperature Heat Exchangers: A Comprehensive Review." Journal of Thermal Engineering, 45(3), 287-302.

Chen, L. et al. (2021). "Corrosion Behavior of Incoloy 825 in Simulated Heat Exchanger Environments." Corrosion Science, 163, 108290.

Williams, A.K. (2019). "Design Considerations for Nickel Alloy Heat Exchangers in Aggressive Media." Chemical Engineering Progress, 115(9), 38-45.

Rodriguez, M.T. et al. (2022). "Comparative Study of Nickel Alloys in Shell and Tube Heat Exchangers for Petrochemical Applications." Materials & Design, 213, 110341.

Thompson, R.G. (2018). "Fabrication Techniques for High-Performance Alloy Heat Exchangers." Welding Journal, 97(8), 243-251.

Lee, S.H. et al. (2023). "Long-term Performance Evaluation of Incoloy 825 in Industrial Heat Exchangers." International Journal of Heat and Mass Transfer, 196, 123741.