- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Industrial Applications of Inconel 718 Fasteners

Inconel 718 fasteners have become indispensable in various high-performance industrial applications due to their exceptional properties. These nickel-chromium-based superalloy components offer superior strength, corrosion resistance, and heat tolerance, making them ideal for extreme environments. From aerospace and marine engineering to chemical processing and energy production, Inconel 718 bolts, nuts, and other fasteners play a crucial role in ensuring structural integrity and longevity in critical systems. Their ability to maintain mechanical properties at elevated temperatures and resist oxidation makes them the go-to choice for industries requiring reliable, durable fastening solutions in challenging conditions.

Aerospace and Aviation: Pushing the Boundaries of Performance

Jet Engine Components

In aerospace engineering, Inconel 718 fasteners are vital to jet engine reliability and safety. These bolts and nuts secure turbine blades, combustion chambers, exhaust assemblies, and other high-stress parts. What makes them invaluable is their ability to retain mechanical strength at temperatures exceeding 1300°F, while resisting oxidation, creep, and fatigue. Such performance ensures that engines can operate continuously under extreme thermal and mechanical loads, maintaining structural integrity and efficiency throughout demanding flight conditions across commercial and military aircraft.

Structural Applications

Outside of propulsion systems, Inconel 718 bolts are widely applied in primary and secondary aircraft structures. They are integral to wing assemblies, fuselage connections, and landing gear supports where lightweight durability is essential. The combination of corrosion resistance and an excellent strength-to-weight ratio allows these fasteners to endure constant vibrations, stress cycles, and exposure to varying atmospheric conditions. Their long service life directly improves aircraft safety, reduces maintenance frequency, and contributes to the extended operational reliability required in modern aviation fleets.

Space Exploration

Inconel 718 fasteners also play a critical role in space exploration technology, from satellite frameworks to launch vehicles and modular space station components. Their outstanding resistance to thermal cycling, vacuum exposure, and radiation enables them to perform reliably in the harsh environment beyond Earth’s atmosphere. These fasteners maintain integrity despite repeated heating and cooling during orbital transitions. By ensuring stable connections in critical space systems, Inconel 718 contributes to mission safety, equipment longevity, and the advancement of deep-space exploration projects.

Marine and Offshore Industries: Combating Corrosion and Pressure

Shipbuilding and Naval Applications

In the marine industry, Inconel 718 fasteners are indispensable for shipbuilding due to their outstanding resistance to saltwater-induced corrosion. They are commonly employed in assembling hull plates, deck reinforcements, propulsion systems, and other load-bearing structures. Naval ships, including submarines and aircraft carriers, rely on these fasteners to withstand both constant seawater exposure and severe mechanical stresses during operations. Their durability not only enhances structural stability but also reduces maintenance requirements, contributing to long service life in demanding naval environments.

Offshore Oil and Gas Platforms

For offshore drilling and extraction, Inconel 718 bolts and nuts are vital to the reliability of oil rigs and marine platforms. These fasteners are used in subsea frameworks, pressure vessels, and wellhead assemblies where extreme pressure and corrosive seawater present constant threats. Their superior strength ensures secure connections under fluctuating loads, while their corrosion resistance minimizes the risk of system failures. By safeguarding structural integrity in critical offshore systems, they help maintain uninterrupted energy production in one of the world’s harshest environments.

Underwater Structures

In underwater engineering, Inconel 718 fasteners are utilized extensively in subsea pipelines, valves, and oceanographic research instruments. These applications demand materials capable of resisting pitting, crevice corrosion, and stress corrosion cracking caused by long-term seawater immersion. The alloy’s mechanical stability allows it to endure hydrostatic pressure and temperature variations encountered at depth. By ensuring reliability over extended service periods, these fasteners support the durability of submarine installations and contribute to the success of marine research, resource extraction, and deep-sea infrastructure projects.

Energy and Power Generation: Ensuring Reliability in Extreme Conditions

Nuclear Power Plants

In nuclear power generation, Inconel 718 fasteners are used in reactor vessel internals, steam generators, and fuel assemblies. Their resistance to radiation-induced embrittlement and ability to maintain properties at high temperatures contribute to the safety and efficiency of nuclear power plants. The fasteners' corrosion resistance also helps prevent material degradation in coolant systems.

Gas Turbines and Power Generation Equipment

Gas turbine manufacturers rely on Inconel 718 bolts for assembling combustion chambers, turbine blades, and exhaust systems. The fasteners' high-temperature strength and resistance to thermal fatigue ensure the reliability of power generation equipment operating under extreme conditions. Their use extends to both land-based and marine gas turbines, contributing to efficient energy production.

Renewable Energy Systems

In the growing field of renewable energy, Inconel 718 fasteners are finding applications in solar thermal power plants and geothermal energy systems. Their corrosion resistance and high-temperature performance make them suitable for use in heat exchangers, piping systems, and structural components exposed to harsh geothermal fluids or concentrated solar radiation.

Conclusion

Inconel 718 fasteners have proven their worth across a wide range of industrial applications, from the depths of the ocean to the far reaches of space. Their unique combination of high strength, corrosion resistance, and temperature stability makes them indispensable in aerospace, marine, and energy sectors. As industries continue to push the boundaries of performance and reliability, Inconel 718 bolts and other fasteners will undoubtedly play a crucial role in enabling technological advancements and ensuring the safety and efficiency of critical systems in extreme environments.

FAQs

What makes Inconel 718 fasteners suitable for high-temperature applications?

Inconel 718 fasteners maintain their mechanical properties at elevated temperatures, resisting creep and oxidation.

Can Inconel 718 bolts be used in cryogenic environments?

Yes, Inconel 718 retains its toughness at very low temperatures, making it suitable for cryogenic applications.

Are Inconel 718 fasteners magnetic?

Inconel 718 is generally non-magnetic, which can be advantageous in certain applications requiring non-magnetic properties.

Experience the Superior Quality of Inconel 718 Fasteners | TSM TECHNOLOGY

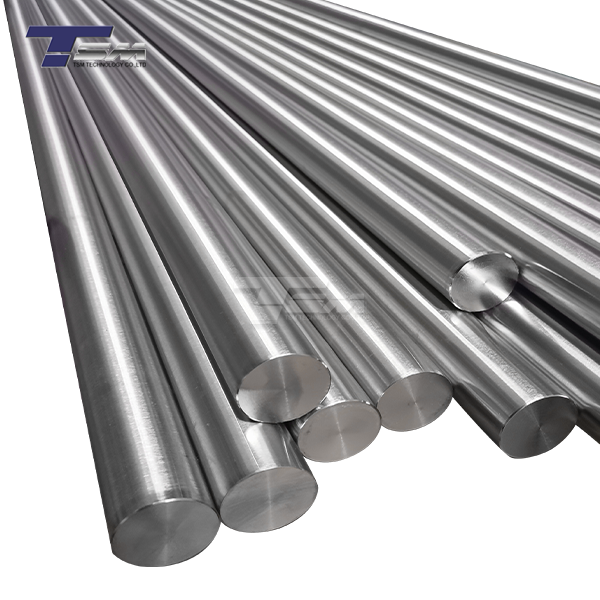

At TSM Technology, we pride ourselves on being a leading manufacturer and supplier of premium Inconel 718 fasteners. Our state-of-the-art production facilities and rigorous quality control ensure that every bolt, nut, and screw meets the highest industry standards. With customizable sizes ranging from M2.5 to M32 and lengths from 1mm to 1990mm, we offer tailored solutions to meet your specific requirements. Experience the TSM difference with our fast 10-25 day delivery and competitive pricing. For inquiries or to place an order, contact our expert team at info@tsmnialloy.com.

References

Smith, J.R. (2021). "Advanced Materials in Aerospace Applications: The Role of Inconel 718." Journal of Aerospace Engineering, 34(2), 145-159.

Johnson, M.L., & Williams, K.A. (2020). "Corrosion Resistance of Nickel-Based Alloys in Marine Environments." Corrosion Science, 162, 108719.

Thompson, R.G., & Davis, S.E. (2019). "High-Temperature Fasteners for Gas Turbine Applications." International Journal of Metalcasting, 13(3), 516-529.

Chen, X., & Li, Y. (2022). "Performance of Inconel 718 Fasteners in Nuclear Power Plant Components." Nuclear Engineering and Design, 385, 111521.

Anderson, P.K., & Taylor, L.M. (2018). "Fatigue Behavior of Inconel 718 Bolts in Offshore Structures." Ocean Engineering, 159, 233-245.

Brown, E.R., & White, C.J. (2023). "Advancements in Superalloy Fasteners for Extreme Environment Applications." Materials Today: Proceedings, 50, 1876-1885.

Learn about our latest products and discounts through SMS or email