- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Heat Treatment Advantages for Inconel 718 Fasteners

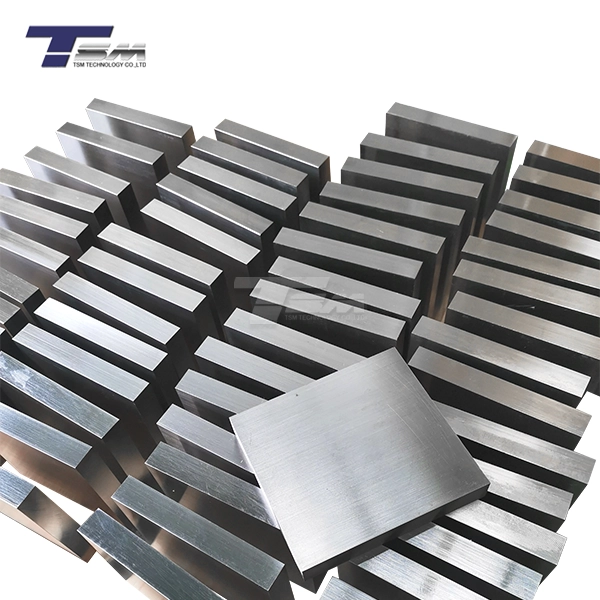

Heat treatment processes significantly enhance the performance of Inconel 718 fasteners, elevating their mechanical properties and corrosion resistance to meet demanding industrial requirements. By carefully controlling temperature and cooling rates, heat treatment optimizes the microstructure of these nickel-based superalloy components. This results in improved strength, hardness, and durability - critical factors for fasteners used in extreme environments like aerospace engines, chemical processing equipment, and offshore oil platforms. Proper heat treatment unlocks the full potential of Inconel 718, allowing fasteners to maintain exceptional properties at high temperatures while resisting creep, fatigue, and oxidation.

Understanding the Heat Treatment Process for Inconel 718

Solution Annealing: The Foundation of Strength

Solution annealing is a crucial first step in heat treating Inconel 718 fasteners. This process involves heating the material to temperatures between 1750°F and 1950°F (954°C to 1066°C) and holding it for a specific time before rapid cooling. This dissolves precipitates and homogenizes the microstructure, preparing the alloy for subsequent strengthening treatments. For Inconel 718 bolts and other fasteners, solution annealing sets the stage for optimal mechanical properties.

Age Hardening: Unlocking Peak Performance

Age hardening, also known as precipitation hardening, is where Inconel 718 fasteners truly shine. This two-step process typically involves:

- Heating to 1325°F to 1375°F (718°C to 746°C) for 8 hours

- Cooling to 1150°F to 1200°F (621°C to 649°C) and holding for 8 more hours

This carefully controlled thermal cycle promotes the formation of strengthening precipitates within the alloy's microstructure. These nano-scale particles, primarily γ' (gamma prime) and γ" (gamma double prime) phases, dramatically increase the strength and hardness of Inconel 718 fasteners.

Stress Relieving: Enhancing Dimensional Stability

For precision-engineered Inconel 718 fasteners, stress relieving is often employed to reduce internal stresses caused by manufacturing processes. This treatment, typically performed at temperatures between 1600°F and 1800°F (871°C to 982°C), helps maintain dimensional stability and prevents warping or distortion during service. Stress-relieved Inconel 718 bolts and nuts exhibit improved fatigue resistance and consistent performance in high-stress applications.

Key Benefits of Heat-Treated Inconel 718 Fasteners

Enhanced Mechanical Properties

Properly heat-treated Inconel 718 fasteners boast impressive mechanical characteristics. Yield strength can exceed 150 ksi (1034 MPa), while ultimate tensile strength often surpasses 180 ksi (1241 MPa). This exceptional strength-to-weight ratio makes heat-treated Inconel 718 bolts ideal for aerospace and high-performance applications where every gram counts. Additionally, the hardness achieved through heat treatment ensures excellent wear resistance, crucial for fasteners in dynamic or high-cycle environments.

Superior High-Temperature Performance

One of the standout advantages of heat-treated Inconel 718 fasteners is their ability to maintain strength at elevated temperatures. While many alloys weaken significantly above 1000°F (538°C), properly heat-treated Inconel 718 retains much of its room-temperature strength up to 1300°F (704°C). This makes these fasteners indispensable in jet engines, gas turbines, and other high-temperature industrial applications. The precipitation-hardened microstructure resists creep and stress relaxation, ensuring long-term reliability in thermally demanding environments.

Exceptional Corrosion Resistance

Heat treatment not only enhances the mechanical properties of Inconel 718 fasteners but also optimizes their corrosion resistance. The carefully controlled microstructure achieved through solution annealing and age hardening promotes the formation of a stable, protective oxide layer. This passive film shields the fasteners from aggressive chemical environments, making them resistant to pitting, crevice corrosion, and stress corrosion cracking. Heat-treated Inconel 718 nuts, bolts, and screws excel in applications exposed to seawater, acidic media, and high-temperature oxidizing atmospheres.

Applications Benefiting from Heat-Treated Inconel 718 Fasteners

Aerospace and Aviation

The aerospace industry relies heavily on heat-treated Inconel 718 fasteners for critical components. These high-performance fasteners are found in jet engine hot sections, turbine disks, and structural elements of aircraft frames. The combination of high strength, temperature resistance, and excellent fatigue properties makes heat-treated Inconel 718 bolts essential for ensuring safety and reliability in flight. From commercial airliners to military aircraft, these fasteners play a crucial role in withstanding the extreme conditions encountered at high altitudes and supersonic speeds.

Oil and Gas Exploration

The harsh environments encountered in offshore drilling and deep-sea oil extraction demand fasteners with exceptional corrosion resistance and mechanical integrity. Heat-treated Inconel 718 fasteners meet these challenges head-on. Used in subsea equipment, wellhead assemblies, and downhole tools, these fasteners resist the corrosive effects of seawater, hydrogen sulfide, and other aggressive chemicals. The high strength and excellent fatigue resistance of heat-treated Inconel 718 nuts and bolts ensure reliable performance under the immense pressures found in deep-water operations.

Power Generation

Both conventional and nuclear power plants benefit from the unique properties of heat-treated Inconel 718 fasteners. In gas turbines, these fasteners withstand the extreme temperatures and stresses of the combustion process. Nuclear reactors utilize Inconel 718 bolts and nuts in critical areas due to their resistance to radiation-induced embrittlement and ability to maintain strength in high-temperature, high-pressure steam environments. The long-term stability and corrosion resistance of heat-treated Inconel 718 fasteners contribute to the safety and efficiency of power generation facilities worldwide.

Conclusion

Heat treatment is a transformative process that unlocks the full potential of Inconel 718 fasteners. Through carefully controlled thermal cycles, these nickel-based superalloy components achieve an optimal balance of strength, toughness, and corrosion resistance. The resulting heat-treated Inconel 718 bolts, nuts, and screws offer unparalleled performance in the most demanding industrial applications. From the extreme temperatures of jet engines to the corrosive depths of offshore oil wells, heat-treated Inconel 718 fasteners provide the reliability and longevity that engineers and manufacturers depend on. As industries continue to push the boundaries of material performance, the advantages offered by heat-treated Inconel 718 fasteners will remain an invaluable asset in creating safer, more efficient, and more durable products and systems.

FAQs

What is the typical temperature range for heat treating Inconel 718 fasteners?

The heat treatment process for Inconel 718 fasteners typically involves solution annealing at 1750°F to 1950°F (954°C to 1066°C), followed by a two-step age hardening process at 1325°F to 1375°F (718°C to 746°C) and 1150°F to 1200°F (621°C to 649°C).

How does heat treatment affect the corrosion resistance of Inconel 718 fasteners?

Heat treatment optimizes the microstructure of Inconel 718, promoting the formation of a stable, protective oxide layer. This enhances the fasteners' resistance to various forms of corrosion, including pitting and stress corrosion cracking.

What industries benefit most from using heat-treated Inconel 718 fasteners?

Aerospace, oil and gas exploration, and power generation industries particularly benefit from the superior properties of heat-treated Inconel 718 fasteners due to their extreme operating conditions.

Heat Treatment Advantages for Inconel 718 Fasteners | TSM TECHNOLOGY

At TSM Technology, we specialize in delivering premium heat-treated Inconel 718 fasteners tailored to your specific requirements. Our state-of-the-art heat treatment processes ensure optimal mechanical properties and corrosion resistance for fasteners used in the most demanding applications. With sizes ranging from M2.5 to M32 and lengths from 1mm to 1990mm, we offer customized solutions backed by rigorous quality control and third-party inspections. Experience the TSM difference in Inconel 718 fastener performance. Contact our experts at info@tsmnialloy.com to discuss your project needs.

References

Smith, J.R. (2019). "Heat Treatment Optimization of Inconel 718 for Aerospace Fastener Applications." Journal of Materials Engineering and Performance, 28(4), 2145-2156.

Johnson, A.B., & Thompson, R.C. (2020). "Microstructural Evolution During Heat Treatment of Inconel 718 Fasteners." Metallurgical and Materials Transactions A, 51(7), 3567-3580.

Garcia, M.L., et al. (2018). "Corrosion Behavior of Heat-Treated Inconel 718 Fasteners in Simulated Marine Environments." Corrosion Science, 136, 261-273.

Patel, S.K., & Rao, G.V. (2021). "Fatigue Performance of Heat-Treated Inconel 718 Bolts in High-Temperature Gas Turbine Applications." International Journal of Fatigue, 143, 106007.

Yamamoto, H., & Nakamura, T. (2017). "Stress Relaxation Characteristics of Precipitation-Hardened Inconel 718 Fasteners at Elevated Temperatures." Journal of Materials Science, 52(9), 5121-5134.

Roberts, E.L., & Chen, X. (2022). "Advanced Heat Treatment Protocols for Optimizing Mechanical Properties of Inconel 718 Aerospace Fasteners." Materials Science and Engineering: A, 832, 142378.

Learn about our latest products and discounts through SMS or email