- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

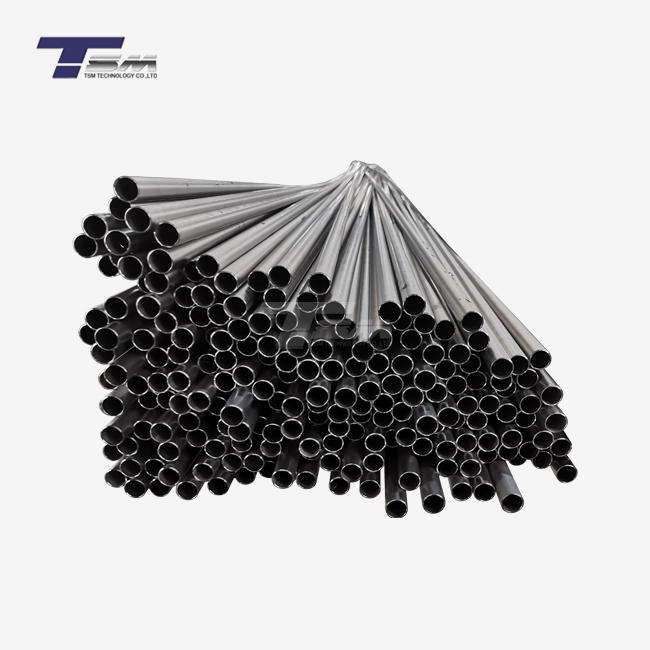

Key Testing Methods for Nickel 201 Tube Quality

Ensuring the quality of Nickel 201 tubes is crucial for their performance in demanding industrial applications. Key testing methods for Nickel 201 tube quality encompass a range of techniques, including chemical composition analysis, mechanical property testing, and non-destructive examinations. These tests verify the material's purity, strength, and structural integrity. Advanced methods like spectroscopy and ultrasonic testing are employed to detect any impurities or defects that could compromise the tube's performance. By rigorously applying these testing methods, manufacturers can guarantee that Nickel 201 tubes meet the stringent standards required for critical applications in aerospace, chemical processing, and energy sectors.

Chemical Composition and Purity Testing

Spectrometric Analysis

Spectrometric analysis is a cornerstone in verifying the chemical composition of Nickel 201 tubes. This method uses advanced optical emission or X-ray fluorescence spectroscopy to precisely quantify the elemental makeup of the alloy. By exciting atoms within the sample, these techniques can detect and measure the concentration of various elements, ensuring that the Nickel 201 composition falls within the specified ranges. This analysis is crucial for confirming the high nickel content (typically 99% or greater) and monitoring trace elements that can affect the tube's properties.

Carbon Content Analysis

Given the importance of low carbon content in Nickel 201 alloy, specific tests are conducted to measure carbon levels accurately. Combustion analysis is commonly employed, where a small sample is heated to high temperatures in an oxygen-rich environment. The resulting carbon dioxide is measured, providing a precise determination of carbon content. This test is vital because even slight variations in carbon can significantly impact the alloy's performance, particularly in high-temperature applications where carbon migration can lead to embrittlement.

Trace Element Detection

Advanced analytical techniques such as inductively coupled plasma mass spectrometry (ICP-MS) are used for detecting and quantifying trace elements in Nickel 201 tubes. This ultra-sensitive method can identify elements present in parts per billion, ensuring that harmful impurities are kept below critical thresholds. Trace elements like sulfur, which can severely affect corrosion resistance, are carefully monitored. This level of scrutiny helps maintain the exceptional purity required for applications in industries such as semiconductor manufacturing and pharmaceutical processing.

Mechanical Property Evaluation

Tensile Strength Testing

Tensile strength testing is a fundamental assessment of Nickel 201 tube quality. This test involves applying a controlled, gradually increasing load to a tube sample until failure occurs. Key parameters measured include yield strength, ultimate tensile strength, and elongation. For Nickel 201 tubes, which are known for their excellent ductility, the elongation values are particularly important. These tests are typically conducted at room temperature, but may also be performed at elevated temperatures to simulate actual service conditions in heat exchangers or chemical processing equipment.

Hardness Measurement

Hardness testing provides valuable insights into the material's resistance to deformation and wear. For Nickel 201 tubes, Rockwell or Vickers hardness tests are commonly employed. These non-destructive methods involve applying a standardized force to the tube surface using a diamond indenter. The resulting indentation size correlates to the material's hardness. This test is crucial for quality control, as it can indicate variations in the material's structure or composition that might affect its performance in applications where wear resistance is critical, such as in pumps or valves handling abrasive fluids.

Fatigue Resistance Evaluation

Given the cyclic loading often encountered in industrial applications, fatigue resistance testing is essential for Nickel 201 tubes. This involves subjecting tube samples to repeated stress cycles, typically using rotating beam or axial loading methods. The number of cycles to failure at different stress levels is recorded to generate S-N curves (stress vs. number of cycles). These tests help predict the long-term performance of Nickel 201 tubes in applications with fluctuating loads, such as in heat exchangers or pressure vessels. The excellent fatigue resistance of Nickel 201 is a key factor in its selection for critical components in the aerospace and energy sectors.

Non-Destructive Examination Techniques

Ultrasonic Testing

Ultrasonic testing is a crucial non-destructive examination technique for Nickel 201 tubes. This method uses high-frequency sound waves to detect internal defects without compromising the tube's integrity. Advanced ultrasonic systems can identify minute flaws such as inclusions, voids, or cracks that might be invisible to the naked eye. For Nickel 201 tubes, which are often used in critical applications like nuclear power plants, this level of inspection is invaluable. The technique can be applied to both seamless and welded tubes, ensuring uniformity and structural soundness throughout the entire length of the product.

Eddy Current Inspection

Eddy current testing is another non-destructive method widely used for Nickel 201 tube quality assurance. This electromagnetic technique is particularly effective in detecting surface and near-surface defects. By inducing electrical currents in the tube material, any disruptions in the current flow caused by flaws can be detected and analyzed. This method is especially useful for identifying subtle imperfections in the tube's surface, which is crucial for maintaining the corrosion resistance of Nickel 201 in aggressive chemical environments. Eddy current testing can be automated for high-speed inspection of large quantities of tubing, making it an efficient quality control tool in production settings.

Radiographic Examination

Radiographic examination, using X-rays or gamma rays, provides a comprehensive view of the internal structure of Nickel 201 tubes. This technique is particularly valuable for inspecting weld joints in fabricated tube assemblies. The high-density nature of nickel alloys requires careful selection of radiation sources and exposure times to achieve clear, interpretable images. Advanced digital radiography systems allow for enhanced image processing and analysis, enabling the detection of subtle variations in material density that might indicate flaws or inconsistencies. This level of inspection is critical for Nickel 201 tubes used in high-pressure or high-temperature applications where the consequences of failure could be severe.

Conclusion

The comprehensive suite of testing methods employed for Nickel 201 tubes ensures their quality and reliability in demanding industrial applications. From chemical composition analysis to mechanical property evaluation and non-destructive examinations, each test plays a crucial role in verifying the material's integrity. These rigorous quality control measures are essential for maintaining the exceptional performance characteristics of Nickel 201 tubes, including their superior corrosion resistance, high thermal conductivity, and excellent mechanical properties. By adhering to these testing protocols, manufacturers can guarantee that Nickel 201 tubes meet the exacting standards required for critical applications across various industries, from aerospace to chemical processing.

FAQs

What are the key properties that make Nickel 201 tubes suitable for corrosive environments?

Nickel 201 tubes excel in corrosive environments due to their high nickel purity, exceptional resistance to caustic alkalis and acids, and low carbon content. These properties contribute to their superior performance in chemical processing and marine applications.

How does the thermal conductivity of Nickel 201 tubes compare to other alloys?

Nickel 201 tubes offer high thermal conductivity compared to many other nickel alloys, making them ideal for heat exchanger applications. This property, combined with their corrosion resistance, makes them particularly suitable for use in demanding thermal management systems.

Can Nickel 201 tubes be used in high-temperature applications?

Yes, Nickel 201 tubes perform well in high-temperature environments. Their low carbon content prevents embrittlement at elevated temperatures, allowing them to maintain their mechanical properties and corrosion resistance in applications such as furnace components and nuclear power plant equipment.

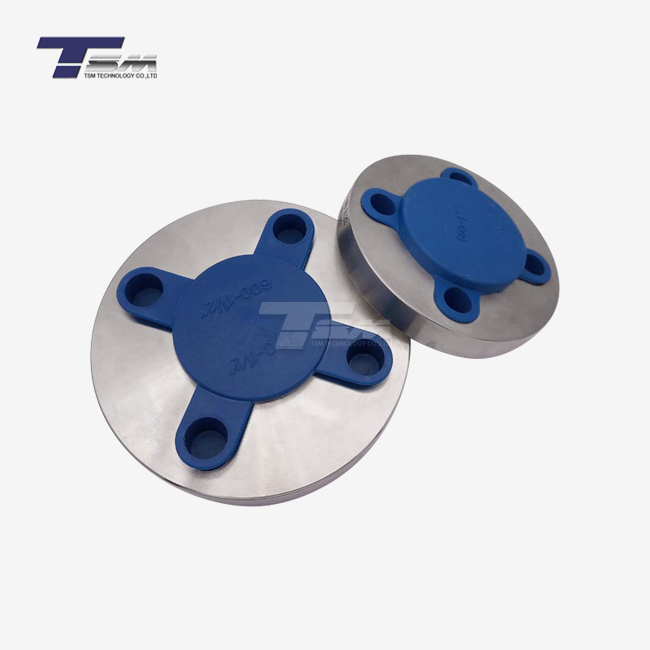

Trust TSM TECHNOLOGY for Premium Nickel 201 Tubes

At TSM TECHNOLOGY, we pride ourselves on delivering top-quality Nickel 201 tubes that consistently meet and exceed industry standards. Our state-of-the-art testing facilities and rigorous quality control processes ensure that every tube we produce is of the highest caliber. With our extensive experience and commitment to excellence, we offer customized solutions to meet your specific needs. For premium Nickel 201 tubes from a reliable manufacturer, choose TSM TECHNOLOGY. Contact us at info@tsmnialloy.com to discuss your requirements and experience our superior service firsthand.

References

ASTM International. (2020). "Standard Specification for Nickel Seamless Pipe and Tube." ASTM B161-20.

ASM International. (2018). "Nickel and Nickel Alloys: Properties and Performance." ASM Handbook, Volume 2B.

American Society for Nondestructive Testing. (2019). "Nondestructive Testing Handbook: Ultrasonic Testing." 4th Edition.

Journal of Materials Engineering and Performance. (2021). "Advances in Mechanical Testing of Nickel Alloys for High-Temperature Applications."

Corrosion Science. (2020). "Electrochemical Behavior of Pure Nickel in Aggressive Environments: A Comprehensive Review."

International Journal of Fatigue. (2019). "Fatigue Properties and Crack Propagation in Nickel-Based Alloys for Industrial Applications."

Learn about our latest products and discounts through SMS or email