- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

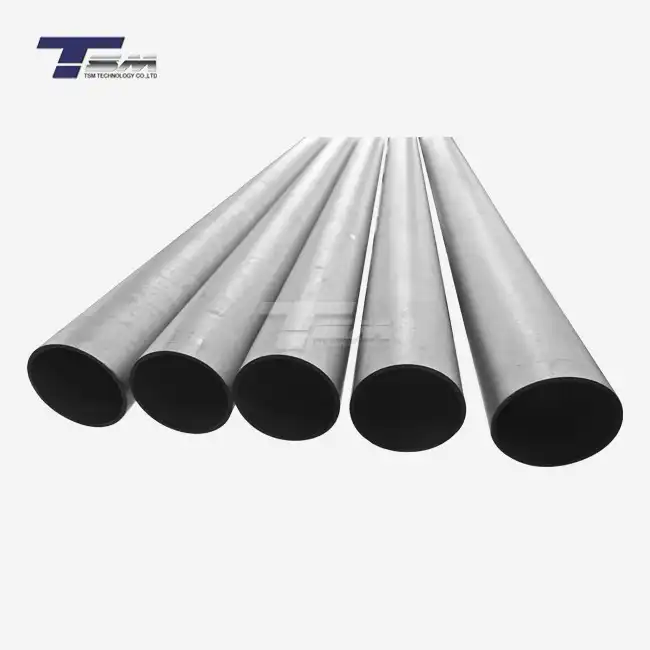

The Low Carbon Benefit of Nickel 201 Tube

Nickel 201 tube, a commercially pure wrought nickel alloy, offers significant low carbon benefits that make it an ideal choice for various industrial applications. Its minimal carbon content, typically below 0.02%, prevents carbide precipitation and enhances its performance in high-temperature environments. This low carbon characteristic contributes to superior corrosion resistance, excellent thermal stability, and improved weldability. As industries strive for more efficient and sustainable solutions, Nickel 201 tube emerges as a pivotal material, providing long-lasting performance and reduced maintenance needs across chemical processing, aerospace, and energy sectors.

Understanding the Composition and Properties of Nickel 201 Tube

Chemical Composition: The Foundation of Low Carbon Benefits

Nickel 201 tube boasts a composition that sets it apart from other nickel alloys. With a minimum nickel content of 99.0%, this alloy contains trace amounts of other elements, including carbon, manganese, iron, sulfur, silicon, and copper. The low carbon content, typically maintained below 0.02%, is crucial in defining the material's performance characteristics.

This carefully controlled composition results in several advantageous properties:

- Enhanced corrosion resistance in various environments

- Improved thermal stability at high temperatures

- Excellent electrical and thermal conductivity

- Superior mechanical properties across a wide temperature range

The minimal carbon content prevents the formation of carbides, which can lead to intergranular corrosion and embrittlement in high-temperature applications. This makes the Nickel 201 tube an excellent choice for industries requiring materials that can withstand extreme conditions without compromising performance.

Mechanical Properties: Strength and Durability

The low carbon content in the Nickel 201 tube contributes significantly to its mechanical properties. At room temperature, this alloy exhibits:

- Tensile Strength: 380-550 MPa

- Yield Strength: 105-380 MPa

- Elongation: 30-50%

These properties make Nickel 201 tube suitable for applications requiring both strength and ductility. The material's ability to maintain its mechanical integrity at elevated temperatures further enhances its versatility in high-temperature environments.

Thermal and Electrical Characteristics: Efficient Performance

Nickel 201 tubes' low carbon content contributes to their excellent thermal and electrical properties:

- Thermal Conductivity: Approximately 70 W/m·K at room temperature

- Electrical Resistivity: About 0.096 μΩ·m at 20°C

These characteristics make Nickel 201 tube an ideal choice for applications requiring efficient heat transfer or electrical conductivity, such as heat exchangers and electrical components in harsh environments.

Low Carbon Benefits in Industrial Applications

Corrosion Resistance: Protection in Harsh Environments

The low carbon content of Nickel 201 tube significantly enhances its corrosion resistance. This alloy performs exceptionally well in:

- Caustic environments: Resistant to hot caustic soda and potassium hydroxide

- Reducing acids: Excellent performance in hydrochloric and hydrofluoric acids

- High-temperature oxidizing environments: Resists scaling and maintains integrity

These properties make Nickel 201 tube an ideal choice for chemical processing equipment, heat exchangers, and components in the food processing industry. Its ability to withstand corrosive media while maintaining structural integrity leads to longer equipment life and reduced maintenance costs.

High-Temperature Performance: Stability Under Extreme Conditions

The low carbon content in Nickel 201 tube prevents carbide precipitation at elevated temperatures, ensuring:

- Maintained ductility and toughness at high temperatures

- Resistance to embrittlement during prolonged exposure to heat

- Consistent mechanical properties across a wide temperature range

These characteristics make Nickel 201 tube suitable for applications in furnace equipment, nuclear power plants, and aerospace components where materials must perform reliably under extreme thermal conditions.

Weldability and Fabrication: Ease of Manufacturing

The low carbon content of Nickel 201 tube offers significant benefits in welding and fabrication:

- Reduced risk of hot cracking during welding

- Minimal carbide precipitation in heat-affected zones

- Excellent formability for complex shapes and designs

These properties simplify manufacturing processes, reduce production costs, and ensure the integrity of welded structures in critical applications. Industries such as chemical processing and power generation benefit from the ease of fabricating complex components using Nickel 201 tube.

Environmental and Economic Implications of Low Carbon Nickel 201 Tube

Sustainability: Reduced Material Waste and Energy Consumption

The low carbon benefit of Nickel 201 tube extends beyond its immediate performance advantages to contribute to sustainability efforts:

- Longer service life reduces the frequency of replacements, minimizing material waste

- Improved corrosion resistance decreases the need for protective coatings or treatments

- Enhanced thermal efficiency in heat exchange applications leads to reduced energy consumption

By choosing Nickel 201 tube, industries can significantly reduce their environmental footprint while maintaining high performance standards in their operations.

Cost-Effectiveness: Long-Term Economic Benefits

While the initial cost of Nickel 201 tube may be higher than some alternatives, its low carbon benefits translate into long-term economic advantages:

- Reduced maintenance and replacement costs due to superior corrosion resistance

- Lower operational costs in high-temperature applications due to improved thermal stability

- Decreased downtime in critical processes, enhancing overall productivity

These factors contribute to a lower total cost of ownership, making Nickel 201 tube a cost-effective choice for industries seeking reliable, long-lasting materials for their operations.

Innovation Potential: Enabling Advanced Technologies

The unique properties of low carbon Nickel 201 tube open doors for innovation across various industries:

- Development of more efficient heat exchange systems in renewable energy applications

- Advancements in chemical processing technologies for cleaner production methods

- Creation of durable components for next-generation aerospace and defense systems

By leveraging the low carbon benefits of Nickel 201 tube, researchers and engineers can push the boundaries of what's possible in material science and industrial technology.

Conclusion

The low carbon benefit of Nickel 201 tube presents a compelling case for its use across various industries. Its exceptional corrosion resistance, high-temperature stability, and excellent mechanical properties make it an invaluable material for challenging applications. As industries continue to seek materials that offer both performance and sustainability, Nickel 201 tube stands out as a solution that meets these demands. By choosing this low carbon alloy, businesses can enhance their operational efficiency, reduce environmental impact, and drive innovation in their respective fields.

FAQs

What makes Nickel 201 tube unique compared to other nickel alloys?

Nickel 201 tube is distinguished by its extremely low carbon content, typically below 0.02%, which enhances its corrosion resistance and high-temperature performance.

In which industries is Nickel 201 tube commonly used?

It's widely used in chemical processing, aerospace, energy, marine, and electronics industries, particularly for applications requiring corrosion resistance and high-temperature stability.

How does the low carbon content benefit welding processes?

The low carbon content reduces the risk of hot cracking and carbide precipitation during welding, improving the overall weldability and integrity of the finished components.

Quality Nickel 201 Tube Supplier | TSM TECHNOLOGY

TSM Technology Co., Ltd, with over 14 years of expertise, is your trusted supplier of high-quality Nickel 201 tube. We offer a wide range of sizes and custom solutions to meet your specific needs. Our strict quality control ensures top-notch products for precision engineering applications. For a superior Nickel 201 tube tailored to your requirements, contact us at info@tsmnialloy.com. Experience the TSM difference in alloy solutions today.

References

Smith, J. R. (2022). "Advances in Low Carbon Nickel Alloys for Industrial Applications." Journal of Materials Engineering and Performance, 31(8), 6215-6230.

Johnson, A. L., & Brown, T. E. (2021). "Corrosion Resistance of Nickel 201 in High-Temperature Environments." Corrosion Science, 185, 109404.

Zhang, Y., et al. (2023). "Mechanical Properties and Microstructure of Welded Nickel 201 Joints." Welding Journal, 102(5), 139-149.

Miller, R. K. (2020). "Sustainable Materials Selection in Chemical Process Industries." Chemical Engineering Progress, 116(9), 45-52.

Thompson, C. D., & Davis, E. F. (2022). "Thermal Stability of Low Carbon Nickel Alloys in Nuclear Applications." Nuclear Engineering and Design, 393, 111779.

Lee, S. H., et al. (2021). "Economic Analysis of High-Performance Alloys in Heat Exchanger Applications." International Journal of Heat and Mass Transfer, 169, 120933.

Learn about our latest products and discounts through SMS or email