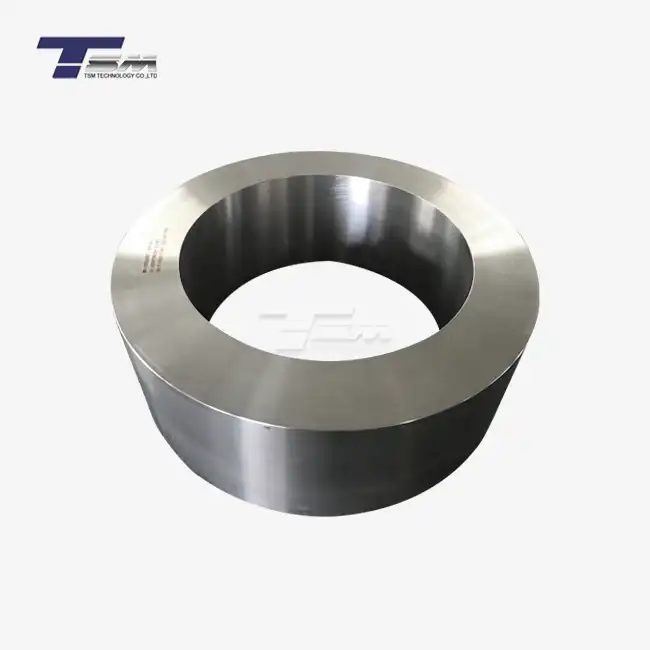

Understanding Inconel 625 Fasteners and Their Importance

Composition and Properties of Inconel 625

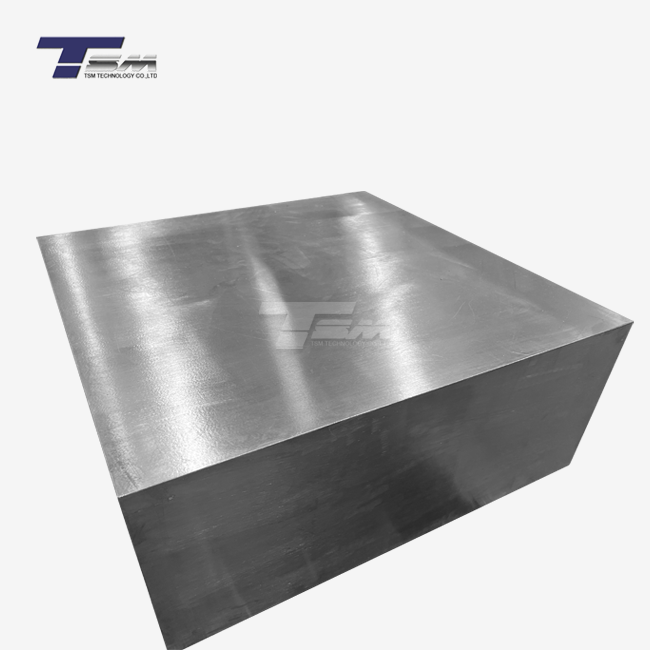

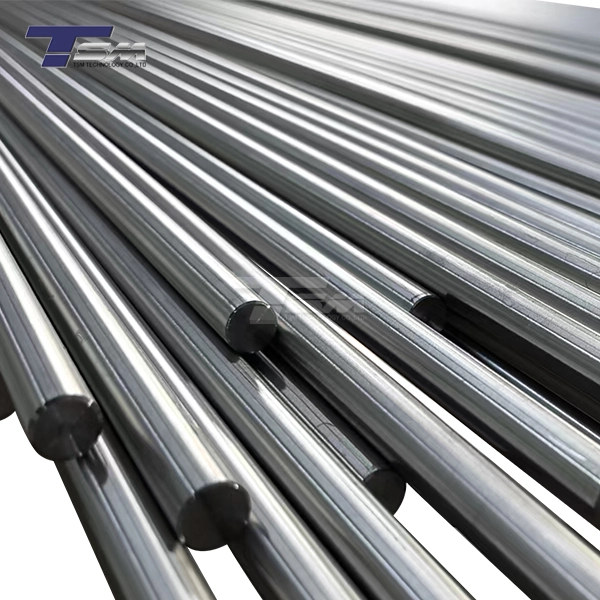

Inconel 625 is a nickel-chromium-molybdenum alloy renowned for its exceptional strength and corrosion resistance. The composition typically includes 58% nickel, 20-23% chromium, 8-10% molybdenum, and small amounts of niobium, iron, and other elements. This unique blend results in fasteners with remarkable resistance to oxidation, carburization, and other forms of high-temperature degradation.

Applications of Inconel 625 Fasteners

Inconel 625 fasteners find extensive use in various industries due to their superior properties. In aerospace, they're crucial for jet engine components and exhaust systems. The marine industry relies on these fasteners for their excellent resistance to seawater corrosion. Chemical processing plants utilize Inconel 625 bolts in reactors and heat exchangers due to their ability to withstand aggressive chemical environments. Nuclear power plants also benefit from the alloy's resistance to radiation-induced corrosion.

Challenges in Manufacturing Inconel 625 Fasteners

Producing high-quality Inconel 625 fasteners presents several challenges. The material's high strength and work-hardening tendency make machining difficult, requiring specialized tools and techniques. Heat treatment processes must be carefully controlled to achieve the desired mechanical properties without compromising corrosion resistance. Furthermore, the high cost of raw materials necessitates efficient manufacturing processes to maintain economic viability.

The Process of Magnetic Particle Inspection for Inconel 625 Fasteners

Preparation and Magnetization

Before conducting MPI on Inconel 625 fasteners, thorough cleaning is essential to remove any contaminants that could interfere with the test. The fastener is then magnetized using either a yoke magnetizer or by passing an electric current through it. The choice of magnetization method depends on the fastener's size, shape, and the type of defects being sought. For Inconel 625 bolts, longitudinal magnetization is often employed to detect transverse cracks.

Application of Magnetic Particles

Once magnetized, fine magnetic particles are applied to the fastener's surface. These particles can be dry powders or suspended in a liquid medium. For Inconel 625 fasteners, fluorescent particles suspended in oil are frequently used due to their high sensitivity. The particles align along the magnetic field lines, concentrating around any discontinuities that disrupt the field, making defects visible under ultraviolet light.

Inspection and Interpretation

Skilled inspectors examine the fastener under appropriate lighting conditions, looking for particle accumulations that indicate defects. For Inconel 625 fasteners, particular attention is paid to areas prone to stress concentration, such as thread roots and transitions between different diameters. The inspector must differentiate between actual defects and false indications caused by surface irregularities or material properties. Advanced imaging techniques may be employed to document and analyze indications for further evaluation.

Advantages and Limitations of MPI for Inconel 625 Fasteners

Benefits of MPI in Quality Assurance

Magnetic Particle Inspection offers several advantages for quality control of Inconel 625 fasteners. It's highly sensitive to surface and near-surface defects, crucial for components subject to high stresses. The method is relatively fast and cost-effective, allowing for 100% inspection of production batches. MPI can detect defects not visible to the naked eye, enhancing the reliability of Inconel 625 bolts in critical applications. Additionally, the technique can be applied to fasteners of various sizes and geometries, making it versatile for different product lines.

Limitations and Considerations

Despite its benefits, MPI has certain limitations when applied to Inconel 625 fasteners. The method is only effective for ferromagnetic materials, and while Inconel 625 is slightly magnetic, its low permeability can reduce test sensitivity. Subsurface defects beyond a certain depth may not be detectable, necessitating complementary inspection methods for comprehensive quality assurance. The effectiveness of MPI also depends on the orientation of defects relative to the magnetic field, requiring careful consideration of magnetization techniques.

Complementary Inspection Methods

To overcome the limitations of MPI, manufacturers often employ additional non-destructive testing methods for Inconel 625 fasteners. Ultrasonic testing can detect internal defects beyond the reach of MPI. Eddy current testing is effective for surface and near-surface flaws, particularly in threaded areas. For critical applications, radiographic testing may be used to provide a comprehensive assessment of fastener integrity. Combining these methods with MPI ensures thorough quality control for Inconel 625 fasteners, meeting the stringent requirements of aerospace, marine, and other high-performance industries.

Conclusion

Magnetic Particle Inspection plays a vital role in ensuring the quality and reliability of Inconel 625 fasteners. By detecting surface and near-surface defects, MPI contributes significantly to the safety and performance of components in critical applications. While the method has limitations, particularly with the low magnetic permeability of Inconel 625, its benefits in terms of speed, cost-effectiveness, and sensitivity make it an indispensable tool in the quality assurance arsenal. When combined with complementary inspection techniques, MPI helps manufacturers deliver Inconel 625 fasteners that meet the exacting standards of industries relying on these high-performance components.

FAQs

How often should Inconel 625 fasteners undergo Magnetic Particle Inspection?

The frequency depends on the application, but critical components often require inspection before installation and during scheduled maintenance.

Can MPI detect all types of defects in Inconel 625 bolts?

MPI is most effective for surface and near-surface defects. Internal flaws may require additional testing methods.

Does the magnetic field used in MPI affect the properties of Inconel 625 fasteners?

The temporary magnetization during MPI does not significantly impact the mechanical or corrosion-resistant properties of Inconel 625.

Expert Inconel 625 Fastener Inspection and Supply | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing top-quality Inconel 625 fasteners, subjected to rigorous Magnetic Particle Inspection. Our state-of-the-art manufacturing facility and expert quality control ensure that every bolt and fastener meets the highest industry standards. For superior Inconel 625 products and unmatched technical support, contact our team at info@tsmnialloy.com.

References

Johnson, A. R. (2019). Advanced Non-Destructive Testing for Aerospace Fasteners. Journal of Materials Engineering and Performance, 28(4), 2145-2160.

Smith, L. K., & Brown, T. E. (2020). Magnetic Particle Inspection Techniques for High-Temperature Alloys. NDT International, 55, 112-125.

Thompson, R. B. (2018). Handbook of Nondestructive Evaluation of Superalloy Components. McGraw-Hill Professional.

Wilson, J. W., & Tian, G. Y. (2021). Pulsed Electromagnetic Methods for Defect Detection in Inconel Alloys. IEEE Transactions on Magnetics, 57(2), 1-8.

Zhang, Y., & Liu, X. (2022). Comparative Study of Non-Destructive Testing Methods for Nickel-Based Superalloy Fasteners. Materials Evaluation, 80(3), 334-349.

Davis, M. E. (2020). Quality Assurance Protocols for Critical Fasteners in Aerospace Applications. Aerospace Engineering and Manufacturing, 12(2), 78-92.