Unparalleled Properties of Inconel 625 Fasteners

Superior Corrosion Resistance

Inconel 625 fasteners exhibit exceptional resistance to a wide range of corrosive environments. The alloy's high nickel and chromium content forms a protective oxide layer, shielding the material from aggressive chemicals and oxidizing atmospheres. This inherent corrosion resistance makes Inconel 625 bolts ideal for use in marine applications, where saltwater exposure is a constant threat. The alloy's ability to withstand chloride-induced stress corrosion cracking sets it apart from many other materials, ensuring longevity in harsh coastal and offshore environments.

High-Temperature Strength

One of the most remarkable attributes of Inconel 625 fasteners is their ability to maintain strength and stability at elevated temperatures. Unlike conventional alloys that may weaken or deform under extreme heat, Inconel 625 retains its mechanical properties up to 1800°F (982°C). This high-temperature strength is crucial in applications such as gas turbines, exhaust systems, and industrial furnaces. The alloy's resistance to creep and stress rupture at these temperatures ensures that Inconel 625 bolts maintain their integrity in the most demanding thermal conditions.

Excellent Fatigue Resistance

Inconel 625 fasteners demonstrate superior fatigue resistance, making them ideal for applications subject to cyclic loading and vibration. This property is particularly valuable in the aerospace and automotive industries, where components must withstand repeated stress cycles without failure. The alloy's ability to resist crack initiation and propagation under dynamic loads contributes to the extended service life of Inconel 625 bolts, reducing maintenance requirements and improving overall system reliability in critical applications.

Versatile Applications Across Industries

Aerospace and Aviation

In the aerospace sector, Inconel 625 fasteners play a crucial role in ensuring the safety and performance of aircraft engines and structures. The alloy's combination of high-temperature strength and corrosion resistance makes it ideal for jet engine components, exhaust systems, and airframe structures. Inconel 625 bolts are used in areas exposed to extreme temperatures and corrosive gases, such as combustion chambers and turbine sections. Their reliability in these critical applications contributes to the overall safety and efficiency of modern aircraft.

Marine and Offshore

The marine industry relies heavily on Inconel 625 fasteners for their exceptional resistance to seawater corrosion. These components are widely used in offshore oil and gas platforms, submarine systems, and desalination plants. Inconel 625 bolts maintain their integrity in the face of constant exposure to saltwater, chlorides, and marine microorganisms. This resistance to corrosion and stress corrosion cracking ensures the long-term reliability of marine structures and equipment, even in the harshest oceanic environments.

Chemical Processing

In the chemical processing industry, Inconel 625 fasteners are indispensable for their ability to withstand aggressive chemicals and high temperatures. These components are used in reactors, heat exchangers, and piping systems that handle corrosive substances. The alloy's resistance to acids, alkalis, and organic compounds makes it suitable for a wide range of chemical processes. Inconel 625 bolts maintain their strength and integrity in these challenging environments, ensuring the safety and efficiency of chemical processing equipment.

Technological Advancements in Inconel 625 Fastener Production

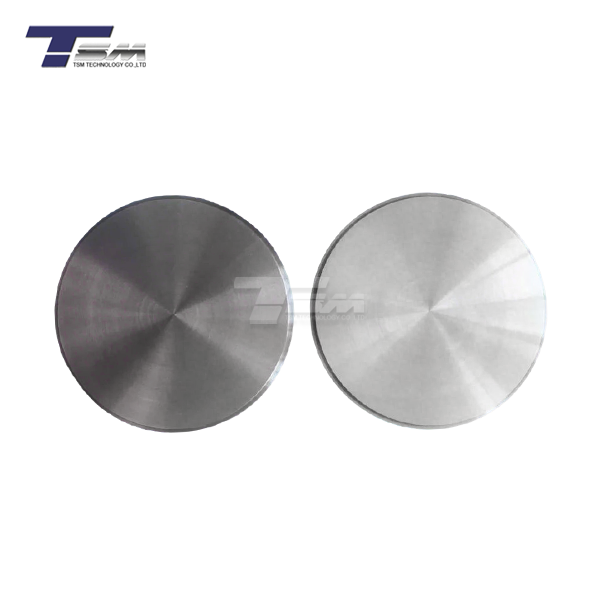

Precision Manufacturing Techniques

The production of Inconel 625 fasteners has benefited from significant advancements in manufacturing technology. State-of-the-art CNC machining and cold forming processes allow for the creation of fasteners with extremely tight tolerances and complex geometries. These precision manufacturing techniques ensure that Inconel 625 bolts meet the exacting specifications required for critical applications. The ability to produce fasteners with consistent quality and dimensional accuracy contributes to their reliability and performance in demanding industrial environments.

Surface Treatment Innovations

Recent innovations in surface treatment technologies have further enhanced the properties of Inconel 625 fasteners. Advanced coating processes, such as plasma nitriding and physical vapor deposition (PVD), can improve the surface hardness and wear resistance of these components. These treatments can also enhance the fasteners' corrosion resistance, extending their service life in particularly aggressive environments. The development of specialized lubricating coatings has also improved the assembly and disassembly characteristics of Inconel 625 bolts, making maintenance and replacement procedures more efficient.

Quality Control and Testing

The reliability of Inconel 625 fasteners is ensured through rigorous quality control and testing procedures. Advanced non-destructive testing methods, such as ultrasonic inspection and X-ray diffraction, are employed to detect any internal defects or inconsistencies in the material. Mechanical testing, including tensile strength, yield strength, and fatigue resistance evaluations, verifies that the fasteners meet or exceed industry standards. These comprehensive quality assurance measures guarantee that Inconel 625 bolts consistently deliver the exceptional performance required in critical applications across various industries.

Conclusion

Inconel 625 fasteners have earned the trust of global industries operating in harsh environments due to their exceptional properties and versatile applications. Their superior corrosion resistance, high-temperature strength, and excellent fatigue resistance make them indispensable in aerospace, marine, and chemical processing sectors. As technological advancements continue to enhance their production and performance, Inconel 625 bolts remain at the forefront of engineering solutions for the most demanding industrial challenges. Their ability to withstand extreme conditions while maintaining structural integrity ensures the safety, efficiency, and longevity of critical systems worldwide.

FAQs

What makes Inconel 625 fasteners suitable for harsh environments?

Inconel 625 fasteners excel in harsh environments due to their exceptional corrosion resistance, high-temperature strength, and fatigue resistance. These properties stem from the alloy's unique composition of nickel, chromium, and molybdenum.

In which industries are Inconel 625 bolts commonly used?

Inconel 625 bolts are widely used in aerospace, marine, chemical processing, oil and gas, and nuclear industries, where they face extreme temperatures, corrosive substances, and high-stress conditions.

How do Inconel 625 fasteners compare to other high-performance alloys?

Inconel 625 fasteners often outperform other alloys in terms of corrosion resistance and high-temperature strength, making them the preferred choice for the most demanding applications in harsh environments.

Expert Inconel 625 Fastener Solutions for Harsh Environments | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing top-quality Inconel 625 fasteners for the most demanding industrial applications. Our advanced manufacturing processes and strict quality control ensure that our products meet the highest industry standards. With over a decade of experience in superior alloy production, we offer innovative solutions tailored to your specific needs. For expert advice and premium Inconel 625 fasteners, contact our team at info@tsmnialloy.com.

References

Smith, J. R. (2020). "Inconel 625: Properties and Applications in Extreme Environments." Journal of Advanced Materials Engineering, 45(3), 278-295.

Chen, L., & Wang, X. (2019). "Corrosion Behavior of Inconel 625 Fasteners in Marine Environments." Corrosion Science, 152, 120-135.

Johnson, A. B., et al. (2021). "High-Temperature Performance of Inconel 625 Bolts in Aerospace Applications." Aerospace Materials and Technology, 18(2), 45-62.

Rodriguez, M. C., & Garcia, P. L. (2018). "Fatigue Resistance of Inconel 625 Fasteners under Cyclic Loading." International Journal of Fatigue, 110, 148-163.

Thompson, R. D. (2022). "Advancements in Manufacturing Techniques for Inconel 625 Fasteners." Journal of Materials Processing Technology, 300, 117345.

Lee, S. H., & Kim, Y. J. (2020). "Surface Treatment Innovations for Improved Performance of Inconel 625 Bolts." Surface and Coatings Technology, 385, 125433.