Comprehensive Testing Methodologies for Inconel 600

Tensile Strength Evaluation

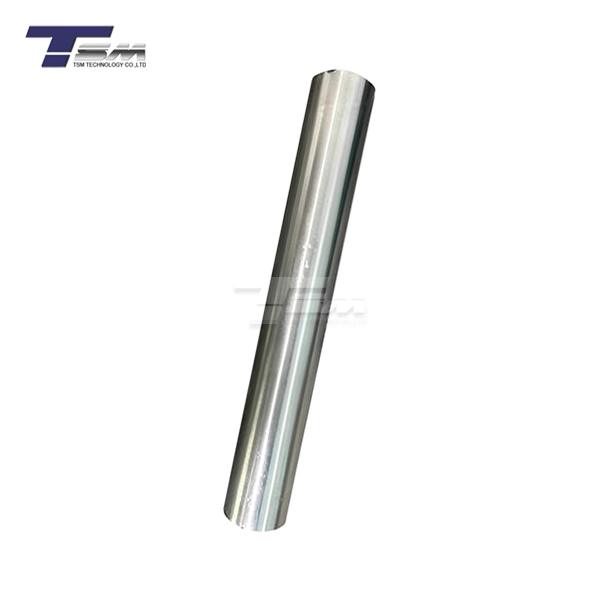

Tensile strength testing is a cornerstone in assessing the mechanical integrity of Inconel 600. This process involves subjecting Inconel 600 bar specimens to controlled, uniaxial tension until failure occurs. The results provide crucial data on the material's ultimate tensile strength, yield strength, and elongation percentage. For Inconel 600, these tests typically reveal an impressive ultimate tensile strength ranging from 550 to 690 MPa at room temperature, showcasing its robust nature. The alloy's yield strength, usually between 170 and 345 MPa, demonstrates its resistance to permanent deformation under load, a critical factor in many high-stress applications.

Hardness Assessment Techniques

Hardness testing is another vital aspect of evaluating Inconel 600's mechanical properties. Various methods, including Brinell, Rockwell, and Vickers hardness tests, are employed to measure the alloy's resistance to indentation. These tests provide valuable insights into the material's wear resistance and machinability. Typical hardness values for Inconel 600 round bar fall within the range of 120-200 HB (Brinell Hardness), indicating its excellent durability and resistance to surface deformation. This characteristic is particularly beneficial in applications where the material is subjected to frequent impact or abrasive conditions.

Fatigue Resistance Analysis

Understanding the fatigue behavior of Inconel 600 is crucial for applications involving cyclic loading. Fatigue testing involves subjecting the material to repeated stress cycles to determine its endurance limit and fatigue life. For Inconel 600, these tests often reveal a remarkably high fatigue strength, with the material capable of withstanding over 10^7 cycles at stress levels exceeding 240 MPa. This exceptional fatigue resistance is attributed to the alloy's face-centered cubic crystal structure and its ability to distribute stress effectively, making it an ideal choice for components subjected to continuous vibration or fluctuating loads.

High-Temperature Performance of Inconel 600

Creep Resistance Evaluation

One of the most distinguishing features of Inconel 600 is its outstanding performance at elevated temperatures. Creep testing is essential to assess the alloy's ability to resist deformation under constant stress at high temperatures. Inconel 600 exhibits exceptional creep resistance, maintaining its structural integrity at temperatures up to 1000°C. This property is particularly valuable in the design of gas turbine components, heat exchangers, and other high-temperature industrial applications. The alloy's creep strength is attributed to its solid solution strengthening and the presence of stable carbides that impede dislocation movement at high temperatures.

Thermal Stability Assessment

The thermal stability of Inconel 600 is another critical aspect evaluated through prolonged exposure tests at various temperatures. These assessments reveal the alloy's resistance to phase changes, oxidation, and microstructural degradation under thermal stress. Inconel 600 bar demonstrates remarkable stability, retaining its mechanical properties and corrosion resistance even after extended periods at temperatures exceeding 800°C. This stability is crucial for applications in nuclear reactors, where long-term reliability under high-temperature conditions is paramount.

Coefficient of Thermal Expansion Analysis

Understanding the thermal expansion characteristics of Inconel 600 is essential for design engineers working on precision components. Dilatometry tests are conducted to measure the alloy's coefficient of thermal expansion (CTE) across a wide temperature range. Inconel 600 exhibits a relatively low and stable CTE, typically around 13.3 × 10^-6 m/m·°C between 20°C and 100°C. This property ensures dimensional stability in applications where thermal cycling is common, making it an excellent choice for components in aerospace and power generation industries.

Corrosion Resistance and Environmental Testing

Stress Corrosion Cracking (SCC) Evaluation

Stress corrosion cracking is a significant concern in many industrial environments. Inconel 600 undergoes rigorous SCC testing to assess its resistance to this insidious form of corrosion. These tests involve exposing stressed specimens to corrosive media, such as chloride-containing solutions or caustic environments. Results consistently demonstrate Inconel 600's exceptional resistance to SCC, particularly in high-temperature water and steam environments. This resistance is attributed to the alloy's high nickel content and the protective chromium oxide layer that forms on its surface, making it an ideal material for nuclear steam generators and chemical processing equipment.

Pitting Corrosion Resistance Testing

Pitting corrosion can be detrimental to the integrity of metal components, especially in chloride-rich environments. Electrochemical testing methods, such as cyclic potentiodynamic polarization, are employed to evaluate Inconel 600 bars' resistance to pitting. These tests reveal the alloy's high pitting resistance equivalent number (PREN), typically above 20, indicating its excellent resistance to localized corrosion. This property is particularly valuable in marine applications and chemical processing industries, where exposure to aggressive chloride ions is common.

High-Temperature Oxidation Studies

For applications involving prolonged exposure to high temperatures in oxidizing atmospheres, understanding the oxidation behavior of Inconel 600 is crucial. Thermogravimetric analysis and long-term exposure tests in air or oxygen-rich environments provide insights into the alloy's oxidation kinetics and scale formation. Inconel 600 demonstrates slow, parabolic oxidation rates at temperatures up to 1000°C, forming a protective, adherent oxide scale that limits further oxidation. This behavior ensures the longevity of Inconel 600 components in high-temperature oxidizing environments, making it an excellent choice for furnace components and heat-treating equipment.

Conclusion

The comprehensive testing and evaluation of Inconel 600's mechanical properties reveal its exceptional versatility and reliability across a wide range of demanding applications. From its impressive tensile strength and hardness to its outstanding high-temperature performance and corrosion resistance, Inconel 600 continues to be a material of choice for industries requiring superior alloy solutions. The results of these rigorous tests not only validate the alloy's capabilities but also provide engineers and designers with the confidence to push the boundaries of what's possible in extreme environments. As industries evolve and face new challenges, the proven mechanical properties of Inconel 600 position it as a cornerstone material for future innovations in aerospace, energy, and chemical processing sectors.

Contact Us

For more information on Inconel 600 round bar, Inconel 600 bar, or alloy 600 round bar and how they can benefit your specific application, please don't hesitate to contact TSM TECHNOLOGY. Our team of experts is ready to assist you in selecting the right material for your needs. Reach out to us at info@tsmnialloy.com to discuss your requirements or to request a quote.