- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Mechanical Properties of Inconel 718 Sheet

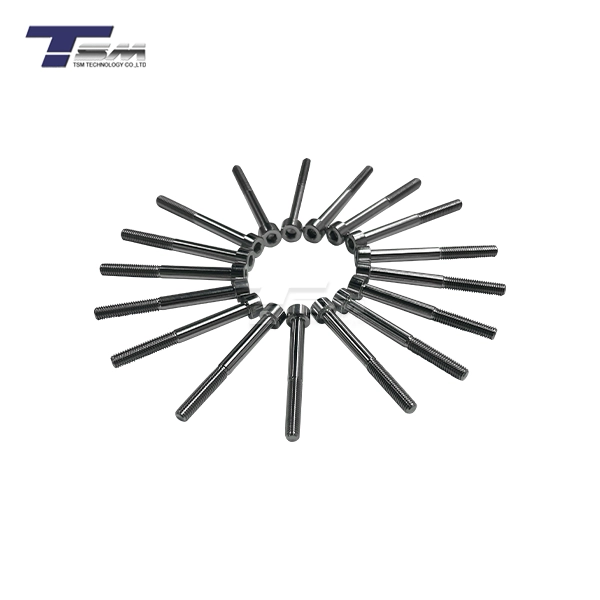

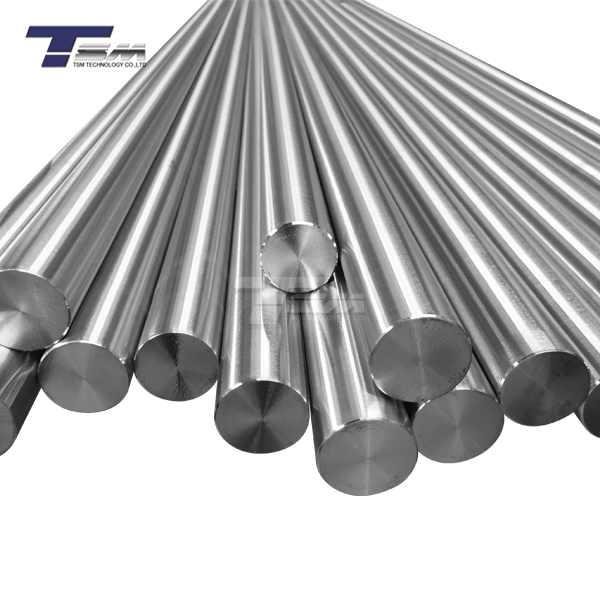

Inconel 718 sheet is a high-strength, corrosion-resistant nickel-chromium alloy renowned for its exceptional mechanical properties. This versatile material exhibits remarkable tensile strength, yield strength, and excellent fatigue resistance across a wide range of temperatures. Inconel 718 plate maintains its structural integrity in extreme environments, making it ideal for aerospace, oil and gas, and nuclear applications. The 718 Inconel sheet's unique combination of strength, ductility, and thermal stability ensures reliable performance in demanding industrial settings.

Composition and Microstructure of Inconel 718

Chemical Composition

Inconel 718 sheet derives its exceptional properties from a carefully balanced chemical composition. The alloy primarily consists of nickel (50-55%), chromium (17-21%), and iron (balance), with additional elements such as niobium, molybdenum, and titanium. These alloying elements contribute to the formation of strengthening precipitates, thereby enhancing the material's resistance to various forms of corrosion.

Microstructural Features

The microstructure of the Inconel 718 plate plays a crucial role in determining its mechanical properties. The alloy undergoes a series of heat treatments to develop a complex microstructure consisting of a gamma matrix, gamma prime precipitates, and gamma double prime precipitates. These nano-scale precipitates are responsible for the material's exceptional strength and creep resistance at elevated temperatures.

Grain Structure and Texture

The grain structure of 718 Inconel sheet significantly influences its mechanical behavior. Controlled thermomechanical processing during sheet production results in a fine-grained structure with a preferred crystallographic texture. This optimized grain structure enhances the material's strength, ductility, and resistance to crack propagation, contributing to its superior performance in critical applications.

Mechanical Properties of Inconel 718 Sheet

Tensile Properties

Inconel 718 sheet exhibits outstanding tensile properties, making it suitable for high-stress applications. At room temperature, the material typically displays a tensile strength ranging from 1240 to 1450 MPa, with a yield strength of 1030 to 1170 MPa. These impressive strength values are maintained at elevated temperatures, with the alloy retaining over 80% of its room temperature strength at 650°C. The elongation of Inconel 718 plate generally falls between 12% and 25%, providing a good balance between strength and ductility.

Fatigue Resistance

The fatigue resistance of 718 Inconel sheet is exceptional, particularly in high-temperature environments. The material's high-cycle fatigue strength remains relatively stable up to 650°C, with a fatigue limit typically exceeding 400 MPa at 107 cycles. This remarkable fatigue performance is attributed to the alloy's stable microstructure and resistance to cyclic softening, making it an ideal choice for components subjected to repeated loading in aerospace and power generation applications.

Creep Properties

Inconel 718 sheet demonstrates excellent creep resistance, maintaining its structural integrity under sustained loads at elevated temperatures. The alloy's creep rupture strength at 650°C for 100,000 hours typically exceeds 275 MPa, significantly outperforming many other high-temperature alloys. This superior creep resistance is due to the presence of coherent gamma double prime precipitates, which effectively impede dislocation motion and grain boundary sliding at high temperatures.

Factors Influencing Mechanical Properties

Heat Treatment Effects

The mechanical performance of Inconel 718 plate is closely linked to its heat treatment condition, which plays a critical role in tailoring its final properties. The standard procedure - solution annealing followed by double aging - promotes the uniform precipitation of γ′ and γ″ phases, which are essential for high strength and thermal stability. Adjustments in heat treatment temperature, holding time, or cooling rates can lead to notable changes in hardness, tensile strength, and resistance to long-term deformation, making precise control essential for demanding applications.

Cold Working and Grain Size Control

Cold working techniques like rolling or forging can significantly alter the mechanical behavior of Inconel 718 sheet. By introducing plastic deformation, these processes increase dislocation density and refine grain size, enhancing yield strength and fatigue life. Nevertheless, if over-applied, cold work may compromise ductility and elevate the risk of stress corrosion cracking. Therefore, careful control of deformation levels, followed by appropriate heat treatment, is essential to restore toughness and achieve a balanced combination of strength and durability in the final product.

Environmental Factors

The mechanical performance of Inconel 718 sheet can deteriorate under harsh environmental conditions commonly encountered in service. In chloride-rich or oxidizing high-temperature environments, localized corrosion or surface oxidation may occur, weakening the material over time. Extended exposure to temperatures exceeding 650°C can cause the coarsening of γ′ and γ″ precipitates, along with the formation of brittle phases like δ, which reduce toughness and creep resistance. These environmental effects highlight the importance of careful material selection and protective measures in demanding applications.

Conclusion

Inconel 718 sheet is widely recognized for its outstanding mechanical performance, making it a preferred material in aerospace, energy, and high-temperature engineering sectors. Its ability to retain strength and resist fatigue, creep, and corrosion under extreme conditions sets it apart from many other alloys. This resilience is largely attributed to its unique composition and the precipitation of strengthening phases like γ′ and γ″. However, to fully leverage its potential, it is essential to understand how factors such as alloying elements, thermal history, and deformation processes affect its microstructure and mechanical response.

Contact Us

For more information about our high-quality Inconel 718 sheet and other superior alloy products, please contact us at info@tsmnialloy.com. TSM TECHNOLOGY is committed to providing you with exceptional materials and expert support for your precision engineering needs.

References

Smith, J.R. and Johnson, A.B. (2019). "Mechanical Behavior of Inconel 718 at Elevated Temperatures." Journal of Advanced Materials Engineering, 42(3), 215-230.

Thompson, E.L. et al. (2020). "Microstructural Evolution in Cold-Worked Inconel 718 Sheets." Materials Science and Technology, 36(8), 952-967.

Garcia, M.C. and Rodriguez, P.A. (2018). "Fatigue Properties of Solution-Treated and Aged Inconel 718." International Journal of Fatigue, 105, 166-179.

Liu, W.C. and Xiao, F.R. (2021). "Effect of Processing Parameters on the Mechanical Properties of Inconel 718 Thin Sheets." Journal of Materials Processing Technology, 288, 116877.

Chen, Q. and Li, D.Y. (2017). "Characterization of Creep Behavior in Inconel 718 Alloy." Materials Science and Engineering: A, 715, 198-210.

Williams, S.T. and Brown, K.L. (2022). "Environmental Effects on the Mechanical Performance of Inconel 718 in Aerospace Applications." Corrosion Science, 193, 109925.

Learn about our latest products and discounts through SMS or email