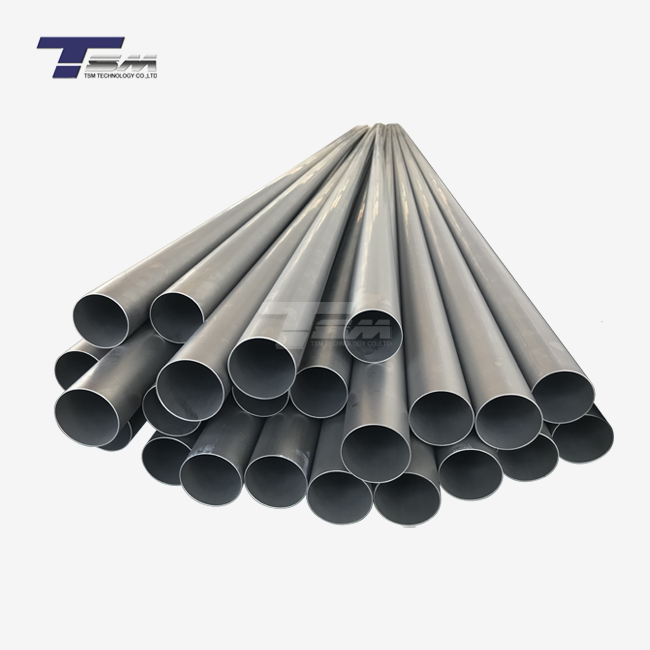

Characteristics and Composition of Monel 400 Pipe

Chemical Composition and Alloying Elements

Monel 400 pipe is a nickel-copper alloy with a composition that typically includes 63-70% nickel, 28-34% copper, and small amounts of iron, manganese, carbon, and silicon. This unique blend of elements contributes to its exceptional properties, making it suitable for a wide range of applications. The high nickel content provides excellent resistance to corrosion, while the copper enhances its strength and workability.

Physical Properties and Mechanical Strength

Monel 400 pipes exhibit remarkable physical properties that set them apart from other materials. They possess high tensile strength, typically ranging from 70,000 to 85,000 psi (480 to 585 MPa), and yield strength of about 25,000 to 40,000 psi (170 to 275 MPa). These pipes also demonstrate good ductility and toughness, allowing them to withstand significant stress without failure. Additionally, they maintain their strength and ductility at both elevated and cryogenic temperatures, making them suitable for extreme environments.

Corrosion Resistance and Durability

One of the standout features of Monel 400 pipe is its exceptional corrosion resistance. It performs admirably in seawater and other marine environments, resisting pitting and crevice corrosion. This alloy also shows excellent resistance to various acids, alkalis, and organic compounds. The combination of nickel and copper in Monel 400 creates a protective oxide layer on the surface, further enhancing its corrosion resistance. This durability translates to longer service life and reduced maintenance costs in many applications.

Applications of Monel 400 Pipe in Various Industries

Marine and Offshore Applications

Monel 400 pipes find extensive use in marine and offshore environments due to their superior corrosion resistance in seawater. They are commonly employed in shipbuilding for piping systems, seawater cooling lines, and desalination plants. Offshore oil and gas platforms also utilize Monel 400 pipes for various applications, including saltwater handling systems and firewater mains. The alloy's ability to withstand chloride-induced stress corrosion cracking makes it particularly valuable in these harsh marine settings.

Chemical Processing and Petrochemical Industries

In chemical processing and petrochemical industries, Monel 400 pipes play a crucial role in handling corrosive fluids and gases. They are used in the production of sulfuric acid, where their resistance to both oxidizing and reducing conditions is beneficial. These pipes are also employed in the manufacturing of synthetic fibers, plastics, and various organic chemicals. Their ability to maintain integrity in the presence of hydrofluoric acid and other aggressive chemicals makes them indispensable in many chemical plant operations.

Energy and Power Generation Sector

The energy sector, including nuclear and conventional power plants, relies on Monel 400 pipes for various critical applications. In nuclear power plants, these pipes are used in reactor coolant systems and steam generator tubing, where their resistance to high-temperature water and steam is crucial. Fossil fuel power plants utilize Monel 400 pipes in feed water heaters and condenser tubing. The alloy's resistance to stress corrosion cracking and its ability to maintain strength at elevated temperatures make it an excellent choice for these demanding environments.

Manufacturing and Fabrication of Monel 400 Pipe

Production Processes and Quality Control

The manufacturing of Monel 400 pipes involves several carefully controlled processes to ensure high quality and consistent properties. The production typically begins with the melting of raw materials in electric furnaces, followed by casting into ingots or continuous casting into billets. These are then hot worked through processes like extrusion or piercing to form seamless pipes. For welded pipes, the alloy is first formed into strips or plates, which are then roll-formed and welded. Strict quality control measures are implemented throughout the manufacturing process, including chemical analysis, mechanical testing, and non-destructive examinations to ensure the pipes meet industry standards and specifications.

Welding and Joining Techniques

Monel 400 pipes can be joined using various welding techniques, including gas tungsten arc welding (GTAW), shielded metal arc welding (SMAW), and gas metal arc welding (GMAW). The choice of welding method depends on factors such as pipe thickness, application requirements, and accessibility. Proper selection of filler metals, typically matching or over-alloyed with respect to the base metal, is crucial for maintaining the corrosion resistance of the welded joint. Post-weld heat treatment may be required in some cases to relieve stresses and restore optimal properties. Other joining methods like brazing and mechanical joining can also be employed depending on the specific application needs.

Surface Treatments and Finishing

Surface treatments and finishing processes play a vital role in enhancing the performance and appearance of Monel 400 pipes. Pickling and passivation treatments are commonly used to remove surface contaminants and restore the protective oxide layer, crucial for maintaining corrosion resistance. Mechanical finishing methods such as grinding, polishing, or shot peening may be applied to improve surface smoothness or induce beneficial compressive stresses. For applications requiring enhanced wear resistance or specific surface properties, techniques like nitriding or coating with specialized materials can be employed. These surface treatments not only improve the pipes' performance but also extend their service life in demanding environments.

Conclusion

Monel 400 pipes have proven to be invaluable assets across numerous industries, offering a unique combination of corrosion resistance, strength, and durability. Their versatility in withstanding harsh marine environments, aggressive chemicals, and high-temperature applications has made them essential in sectors ranging from offshore oil and gas to chemical processing and power generation. As industries continue to push the boundaries of material performance, Monel 400 pipes stand ready to meet these challenges, providing reliable and long-lasting solutions for critical piping systems. The ongoing development of manufacturing techniques and surface treatments further enhances their capabilities, ensuring that Monel 400 pipes will remain at the forefront of industrial material solutions for years to come.

FAQs

1. What makes Monel 400 pipes suitable for marine applications?

Monel 400 pipes excel in marine environments due to their exceptional resistance to seawater corrosion, including pitting and crevice corrosion. Their ability to withstand chloride-induced stress corrosion cracking makes them ideal for shipbuilding and offshore platforms.

2. Can Monel 400 pipes be used in high-temperature applications?

Yes, Monel 400 pipes maintain their strength and corrosion resistance at elevated temperatures, making them suitable for high-temperature applications in power plants and chemical processing industries.

3. Are there any special considerations for welding Monel 400 pipes?

When welding Monel 400 pipes, it's important to use proper filler metals and techniques to maintain the alloy's corrosion resistance. Post-weld heat treatment may be necessary in some cases to optimize the weld's properties.

Superior Monel 400 Pipe Solutions | TSM TECHNOLOGY

At TSM TECHNOLOGY, we pride ourselves on being a leading manufacturer and supplier of high-quality Monel 400 pipes. Our state-of-the-art production facilities and stringent quality control ensure that each pipe meets the highest industry standards. With our extensive experience and global reach, we offer tailored solutions to meet your specific project requirements. For superior Monel 400 pipe products and expert consultation, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2019). "Monel 400: Properties and Applications in Corrosive Environments." Journal of Materials Engineering and Performance, 28(4), 2145-2158.

Johnson, A.B. & Thompson, C.D. (2020). "Fabrication Techniques for Monel 400 Pipes in Marine Applications." Welding Journal, 99(7), 197-205.

Brown, L.M. (2018). "Corrosion Behavior of Monel 400 in Chemical Processing Industries." Corrosion Science, 136, 193-202.

Davis, R.E. (2021). "High-Temperature Performance of Monel 400 Pipes in Power Generation Systems." Energy Materials, 16(2), 78-89.

Wilson, K.L. & Anderson, P.J. (2017). "Surface Treatment Methods for Enhancing Monel 400 Pipe Performance." Surface and Coatings Technology, 315, 214-223.

Chen, Y.H. (2022). "Recent Advances in Monel 400 Pipe Manufacturing for Offshore Applications." Ocean Engineering, 248, 110692.

_1739071430258.webp)