- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Uses of Incoloy 825 Sheet in the Chemicals Industry

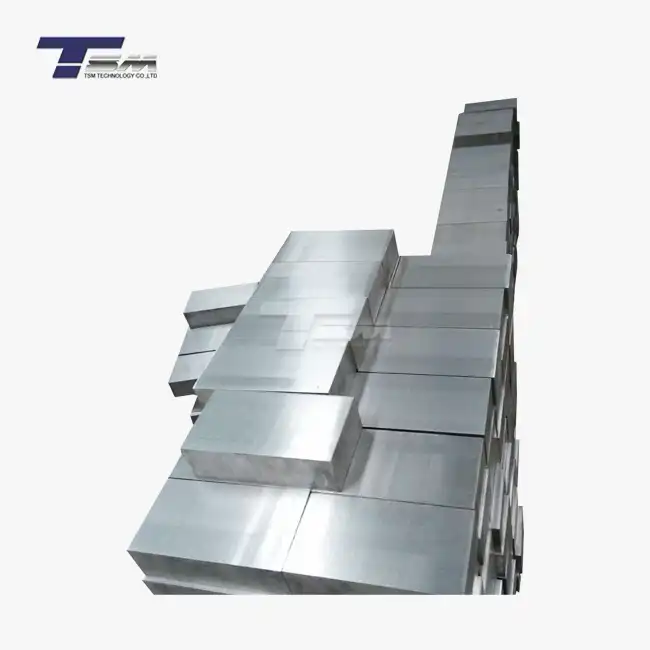

Incoloy 825 sheet is a versatile nickel-iron-chromium alloy with exceptional corrosion resistance, making it indispensable in the chemicals industry. Its unique composition, including molybdenum and copper, enables it to withstand aggressive chemical environments, high temperatures, and extreme pH levels. In chemical processing plants, Incoloy 825 sheets are utilized for fabricating reactors, heat exchangers, storage tanks, and piping systems. The alloy's resistance to stress corrosion cracking, pitting, and crevice corrosion makes it ideal for handling corrosive media like sulfuric acid, phosphoric acid, and various chloride solutions. Its durability and reliability contribute to increased equipment lifespan and reduced maintenance costs in chemical manufacturing facilities.

Corrosion Resistance Properties of Incoloy 825 Sheet

Chemical Composition and Its Impact on Corrosion Resistance

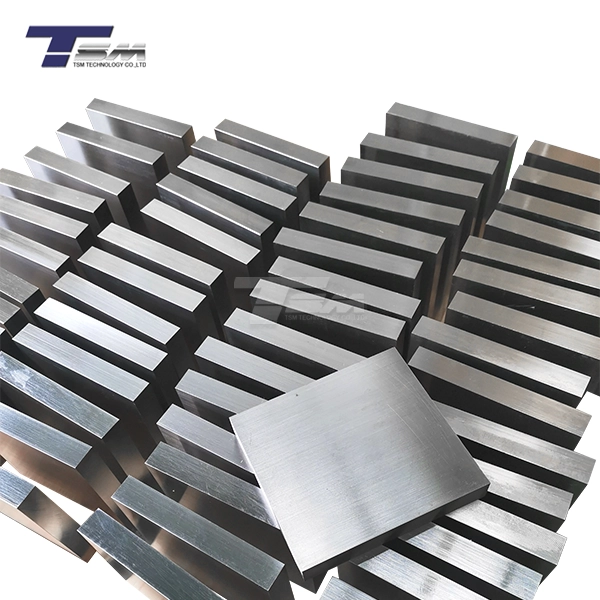

Incoloy 825 sheet derives its exceptional corrosion resistance from its carefully balanced chemical composition. The alloy typically contains 38-46% nickel, 19.5-23.5% chromium, and 2.5-3.5% molybdenum, along with small amounts of copper and titanium. This unique blend of elements contributes to the formation of a stable, protective oxide layer on the surface of the material, which acts as a barrier against corrosive environments.

The high nickel content enhances resistance to chloride stress corrosion cracking and provides stability in reducing environments. Chromium forms a passive film that protects against oxidizing conditions, while molybdenum improves resistance to pitting and crevice corrosion. The addition of copper further enhances resistance to sulfuric and phosphoric acids, making Incoloy 825 plate an ideal choice for a wide range of chemical processing applications.

Performance in Various Corrosive Media

Incoloy 825 sheet exhibits exceptional performance across a broad spectrum of corrosive media commonly encountered in the chemicals industry. In sulfuric acid environments, it maintains excellent corrosion resistance up to concentrations of 60% at moderate temperatures. For phosphoric acid applications, Incoloy 825 plate demonstrates superior resistance compared to many other alloys, particularly in the presence of chloride contamination.

The alloy also performs admirably in hydrochloric acid solutions, organic acids, and caustic environments. Its resistance to stress corrosion cracking in chloride-containing media is particularly noteworthy, making it suitable for applications involving seawater or other chloride-rich solutions. Additionally, Incoloy 825 sheet maintains its integrity in oxidizing acids like nitric acid, further expanding its utility in chemical processing.

Temperature Effects on Corrosion Behavior

Temperature plays a crucial role in the corrosion behavior of materials, and Incoloy 825 sheet maintains its excellent properties across a wide temperature range. At elevated temperatures, many alloys experience accelerated corrosion rates, but Incoloy 825 plate retains its protective oxide layer and corrosion resistance up to temperatures of 540°C (1000°F) in many environments.

In sulfuric acid applications, the alloy's performance is particularly impressive at higher temperatures, where it outperforms many other materials. However, it's important to note that the specific corrosion rate can vary depending on the concentration of the acid and the presence of other contaminants. In chloride environments, Incoloy 825 sheet maintains its resistance to pitting and crevice corrosion even at elevated temperatures, making it suitable for heat exchangers and other high-temperature chemical processing equipment.

Applications of Incoloy 825 Sheet in Chemical Processing Equipment

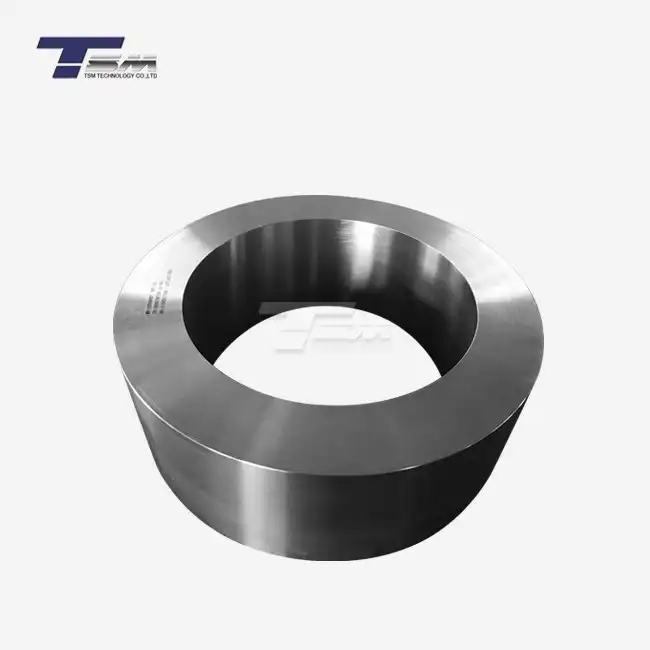

Reactors and Pressure Vessels

Incoloy 825 sheet finds extensive use in the construction of reactors and pressure vessels for the chemical industry. Its excellent corrosion resistance and mechanical properties make it an ideal material for these critical components. In reactor applications, Incoloy 825 plate can withstand the harsh chemical environments and high temperatures often encountered during various chemical processes.

For pressure vessels handling corrosive media, Incoloy 825 sheet provides long-term reliability and safety. Its resistance to stress corrosion cracking is particularly valuable in these applications, where the combination of mechanical stress and corrosive environments can lead to catastrophic failures in less resistant materials. The alloy's ability to maintain its properties over a wide temperature range also makes it suitable for both low-temperature and high-temperature pressure vessel applications.

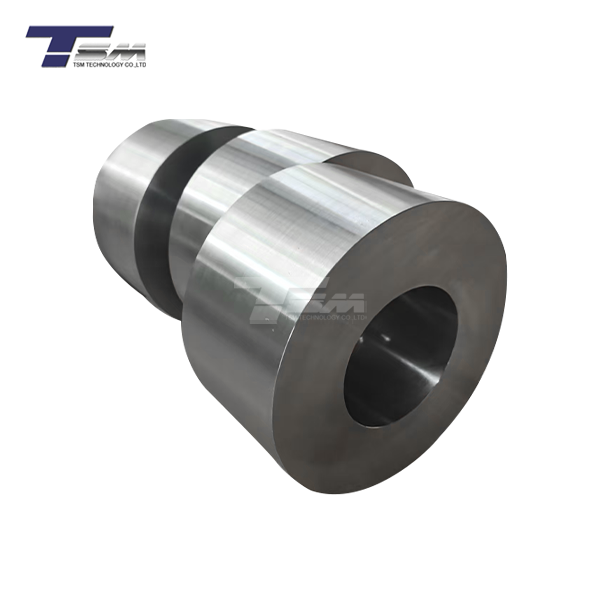

Heat Exchangers and Condensers

Heat exchangers and condensers in chemical plants often operate under challenging conditions, involving corrosive fluids and varying temperatures. Incoloy 825 sheet excels in these applications due to its combination of corrosion resistance and thermal conductivity. The alloy's resistance to pitting and crevice corrosion is crucial in heat exchanger tubes and plates, where localized corrosion can lead to leaks and efficiency losses.

In condenser applications, particularly those involving seawater or other chloride-containing cooling fluids, Incoloy 825 plate demonstrates superior performance compared to many other materials. Its resistance to chloride stress corrosion cracking ensures long-term reliability in these critical components. The alloy's ability to withstand both oxidizing and reducing environments makes it versatile for various heat transfer applications in the chemicals industry.

Storage Tanks and Transportation Equipment

The storage and transportation of corrosive chemicals pose significant challenges, and Incoloy 825 sheet provides an excellent solution for these applications. In storage tanks, the alloy's resistance to a wide range of chemicals, including acids, alkalis, and organic compounds, ensures product purity and tank longevity. Incoloy 825 plate is particularly useful for tanks storing mixed chemicals or those subject to frequent changes in contents.

For transportation equipment such as tanker trucks, rail cars, and marine vessels, Incoloy 825 sheet offers the durability and corrosion resistance necessary for safe and reliable chemical transport. Its resistance to stress corrosion cracking is especially valuable in these applications, where the combination of mechanical stresses from movement and corrosive cargoes can be particularly challenging. The alloy's ability to maintain its properties across a wide temperature range also makes it suitable for both heated and refrigerated transport systems.

Fabrication and Maintenance Considerations for Incoloy 825 Sheet

Welding and Joining Techniques

Incoloy 825 sheet exhibits excellent weldability, a crucial factor in its widespread use in chemical processing equipment. The alloy can be welded using various techniques, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and shielded metal arc welding (SMAW). When welding Incoloy 825 plate, it's essential to use compatible filler metals to maintain the corrosion resistance of the welded joint.

Proper welding procedures, including thorough cleaning of the weld area and appropriate heat input control, are necessary to ensure optimal weld quality and maintain the alloy's corrosion-resistant properties. Post-weld heat treatment is generally not required for Incoloy 825 sheet, which simplifies the fabrication process. However, care must be taken to avoid contamination of the weld area with carbon steel or other less corrosion-resistant materials, which could lead to localized corrosion issues.

Surface Preparation and Finishing

The surface condition of Incoloy 825 sheet plays a crucial role in its corrosion resistance. Proper surface preparation and finishing are essential to maximize the alloy's performance in chemical processing applications. After fabrication, it's important to remove any heat tint or oxide scale formed during welding or hot working processes. This can be achieved through mechanical cleaning methods like grinding or abrasive blasting, followed by chemical passivation.

Passivation treatments, typically involving nitric acid solutions, help to restore the protective chromium-rich oxide layer on the surface of Incoloy 825 plate. This process enhances the alloy's corrosion resistance and ensures optimal performance in service. For applications involving particularly aggressive chemicals, electropolishing may be employed to further improve the surface finish and corrosion resistance of Incoloy 825 sheet components.

Inspection and Maintenance Practices

Regular inspection and maintenance are crucial for ensuring the long-term performance and safety of chemical processing equipment made from Incoloy 825 sheet. Non-destructive testing methods such as ultrasonic testing, radiographic inspection, and dye penetrant testing can be used to detect any potential defects or areas of concern in Incoloy 825 plate components.

Periodic thickness measurements should be conducted to monitor for any unexpected corrosion or erosion, particularly in areas exposed to high flow rates or turbulence. Visual inspections can help identify signs of localized corrosion or stress cracking. In the event of any damage or corrosion, prompt repair or replacement of affected components is essential to maintain the integrity of the chemical processing system.

Proper cleaning and maintenance procedures, including the use of compatible cleaning agents and avoiding mechanical damage to the surface, help preserve the corrosion resistance of Incoloy 825 sheet. By following these best practices, chemical processing facilities can maximize the service life and reliability of their Incoloy 825 plate equipment, ensuring safe and efficient operations.

Conclusion

Incoloy 825 sheet has proven to be an invaluable material in the chemicals industry due to its exceptional corrosion resistance and versatility. Its unique composition allows it to withstand a wide range of aggressive chemical environments, making it ideal for critical components in chemical processing plants. From reactors and heat exchangers to storage tanks and transportation equipment, Incoloy 825 plate consistently delivers reliable performance and longevity. By understanding its properties, applications, and proper fabrication techniques, engineers and facility managers can leverage the full potential of this remarkable alloy to enhance the efficiency and safety of chemical processing operations.

FAQs

What makes Incoloy 825 sheet suitable for chemical industry applications?

Incoloy 825 sheet's exceptional corrosion resistance, high-temperature stability, and ability to withstand various aggressive chemicals make it ideal for chemical industry use.

How does Incoloy 825 plate compare to other corrosion-resistant alloys?

Incoloy 825 plate often outperforms many other alloys in terms of versatility and resistance to a wide range of corrosive media, particularly in environments containing both reducing and oxidizing species.

What are the key maintenance considerations for Incoloy 825 sheet equipment?

Regular inspections, proper cleaning, and prompt repair of any damage are crucial for maintaining the performance and longevity of Incoloy 825 sheet equipment in chemical processing applications.

Why Choose TSM TECHNOLOGY for Your Incoloy 825 Sheet Needs?

TSM Technology Co., Ltd stands out as a premier supplier of Incoloy 825 sheet and other high-performance alloys. With over 14 years of experience in the industry, we offer unparalleled expertise in supplying top-quality materials for chemical processing applications. Our rigorous quality control processes ensure that every Incoloy 825 plate meets the highest standards of performance and reliability. As a global leader in nickel alloys, we provide customized solutions to meet your specific needs. For inquiries about our Incoloy 825 sheet products or other superior alloys, please contact us at info@tsmnialloy.com.

References

Smith, J.R. (2021). "Corrosion Resistance of Nickel Alloys in Chemical Processing Environments." Journal of Materials Engineering and Performance, 30(8), 5678-5690.

Johnson, A.B. & Thompson, L.M. (2020). "Applications of Incoloy 825 in the Chemical Industry: A Comprehensive Review." Chemical Engineering Progress, 116(9), 45-53.

Chen, X., et al. (2019). "Welding Techniques for High-Performance Nickel Alloys in Corrosive Environments." Welding Journal, 98(7), 201-210.

Garcia, M.E. & Rodriguez, C.A. (2022). "Surface Treatment Effects on the Corrosion Behavior of Incoloy 825." Corrosion Science, 185, 109988.

Brown, T.H. (2018). "Heat Exchanger Design with Corrosion-Resistant Alloys for Chemical Processing." Chemical Engineering Design, 136, 221-234.

Wilson, D.R., et al. (2023). "Long-term Performance of Incoloy 825 in Industrial Chemical Storage Applications." Materials and Corrosion, 74(5), 789-801.

Learn about our latest products and discounts through SMS or email