- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Monel 400 Sheet for European PED-Certified Industrial Systems

Monel 400 sheet is a crucial component in European PED-certified industrial systems, offering exceptional corrosion resistance and durability in demanding environments. This nickel-copper alloy excels in applications that require high strength and reliability, making it ideal for use in pressure equipment, heat exchangers, and chemical processing facilities. Monel 400 plates' unique composition enables them to withstand harsh conditions, including exposure to seawater and acidic environments, while maintaining their structural integrity. As industries across Europe strive to meet stringent safety standards, Monel sheet emerges as a top choice for engineers and manufacturers seeking compliance with the Pressure Equipment Directive (PED) while ensuring long-lasting performance in critical systems.

Properties and Advantages of Monel 400 Sheet in PED-Certified Systems

Unparalleled Corrosion Resistance

Monel 400 sheet's exceptional corrosion resistance stems from its balanced nickel-copper composition. This alloy demonstrates remarkable stability in various corrosive media, including seawater, brackish water, and many acids. In PED-certified systems, where material integrity is paramount, Monel 400 plate's ability to resist pitting, crevice corrosion, and stress corrosion cracking makes it an invaluable choice. Its resistance to chloride-induced stress corrosion cracking, in particular, sets it apart from many stainless steel grades, ensuring prolonged equipment life and reduced maintenance costs in marine and chemical processing applications.

Mechanical Strength and Ductility

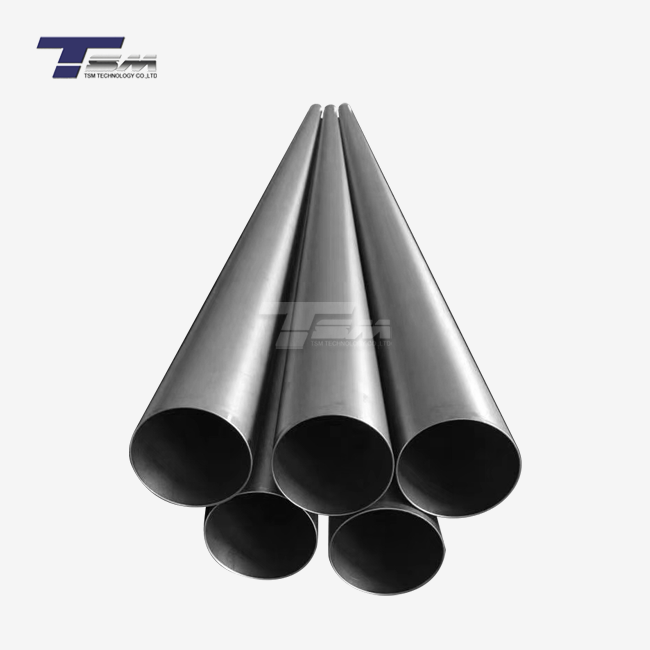

The mechanical properties of Monel 400 sheet contribute significantly to its suitability for PED-certified industrial systems. With a yield strength ranging from 170 to 345 MPa and tensile strength between 480 and 620 MPa, Monel 400 plate offers robust performance under pressure. Its excellent ductility, with elongation typically exceeding 35%, allows for complex forming operations without compromising structural integrity. These characteristics make Monel sheet ideal for fabricating pressure vessels, piping systems, and heat exchanger components that must withstand cyclic loading and thermal stresses while maintaining compliance with European safety standards.

Thermal Stability and Heat Transfer Efficiency

In applications where thermal management is critical, Monel 400 sheet demonstrates superior performance. Its thermal conductivity, approximately 21.8 W/m·K at room temperature, facilitates efficient heat transfer in heat exchangers and thermal processing equipment. Moreover, Monel 400 plate maintains its strength and corrosion resistance at elevated temperatures, with a melting range of 1300-1350°C. This thermal stability ensures reliable operation in high-temperature environments common in petrochemical and power generation industries, where PED certification is often mandatory for pressure-bearing components.

Applications of Monel 400 Sheet in European PED-Certified Industries

Chemical Processing and Petrochemical Sectors

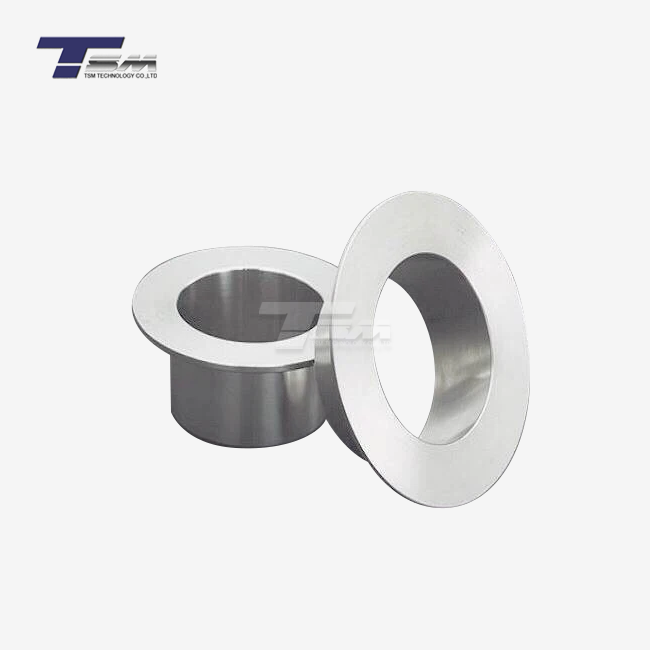

The chemical processing industry relies heavily on Monel 400 sheet for constructing PED-certified equipment exposed to corrosive chemicals. Reactors, distillation columns, and storage tanks benefit from Monel 400 plate's resistance to organic and inorganic acids, alkalis, and salt solutions. In petrochemical refineries, Monel sheet finds applications in heat exchangers, valve bodies, and piping systems handling sulfuric acid and other aggressive media. Its ability to withstand high pressures and temperatures while resisting corrosion makes it an ideal material for ensuring compliance with PED requirements in these critical processes.

Marine and Offshore Engineering

European offshore and marine industries extensively utilize Monel 400 sheet in PED-certified systems exposed to seawater. Desalination plants, offshore platforms, and shipbuilding facilities employ Monel 400 plate in pumps, valves, and heat exchangers due to its exceptional resistance to saltwater corrosion. The alloy's ability to maintain its mechanical properties in chloride-rich environments ensures long-term reliability and safety in marine applications. PED certification for pressure equipment in these sectors often specifies Monel sheet as a preferred material for components subject to constant seawater exposure.

Power Generation and Nuclear Facilities

In the power generation sector, particularly nuclear facilities, Monel 400 sheet plays a crucial role in PED-certified systems. Steam generators, condenser tubing, and valve components in nuclear power plants benefit from Monel 400 plate's resistance to high-temperature steam and its low neutron absorption cross-section. The alloy's stability under radiation exposure and its ability to maintain structural integrity in high-pressure steam environments make it indispensable in these critical applications. PED certification for nuclear power equipment often requires materials with Monel sheet's unique combination of corrosion resistance, strength, and reliability.

Ensuring Compliance and Quality in Monel 400 Sheet for PED-Certified Systems

Material Traceability and Certification

Compliance with PED requirements necessitates rigorous material traceability and certification processes for Monel 400 sheet. Manufacturers must provide detailed documentation, including material test reports, chemical composition analyses, and mechanical property verifications. Each Monel 400 plate undergoes thorough testing to ensure conformity with ASTM B127 or equivalent European standards. Heat treatment records, non-destructive testing results, and surface finish specifications are meticulously documented to facilitate PED certification. This comprehensive traceability ensures that every Monel sheet used in pressure equipment meets the stringent quality and safety standards mandated by European regulations.

Fabrication and Welding Considerations

The fabrication of PED-certified systems using Monel 400 sheet requires specialized knowledge and techniques. Welding procedures for Monel 400 plate must be carefully developed and qualified to maintain the alloy's corrosion resistance and mechanical properties. Techniques such as gas tungsten arc welding (GTAW) and shielded metal arc welding (SMAW) with appropriate filler metals are commonly employed. Post-weld heat treatment and proper cleaning procedures are critical to prevent sensitization and ensure the integrity of welded joints. Fabricators working with Monel sheet for PED-certified equipment must adhere to strict quality control measures, including weld inspection and testing, to guarantee compliance with safety standards.

Ongoing Maintenance and Inspection Protocols

Maintaining PED certification for systems incorporating Monel 400 sheet requires implementing robust maintenance and inspection protocols. Regular non-destructive testing, including ultrasonic thickness measurements and radiographic inspections, helps monitor the condition of Monel 400 plate components over time. Corrosion monitoring programs, utilizing techniques such as electrochemical impedance spectroscopy, can provide early detection of potential issues in critical areas. Implementing these proactive maintenance strategies ensures that PED-certified equipment constructed with Monel sheet continues to meet safety and performance standards throughout its operational life, minimizing the risk of failures and unplanned downtime.

Conclusion

Monel 400 sheet stands as a cornerstone material in the construction of European PED-certified industrial systems, offering an unparalleled combination of corrosion resistance, mechanical strength, and thermal stability. Its versatility across chemical processing, marine engineering, and power generation sectors underscores its importance in ensuring safety, reliability, and longevity in critical applications. As industries continue to face increasingly demanding operational environments, the role of Monel 400 plate in meeting and exceeding PED requirements remains pivotal. By embracing the unique properties of Monel sheet, manufacturers and engineers can confidently design and implement pressure equipment that not only complies with stringent European standards but also delivers exceptional performance in the most challenging industrial settings.

Contact Us

For more information on Monel 400 sheet and its applications in PED-certified systems, contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in selecting the right materials for your industrial needs, ensuring compliance with European standards while maximizing performance and durability.

References

European Commission. (2022). Pressure Equipment Directive (PED) 2014/68/EU. Official Journal of the European Union.

Smith, J. R., & Johnson, A. M. (2021). Corrosion Behavior of Nickel-Copper Alloys in Industrial Environments. Journal of Materials Engineering and Performance, 30(8), 5678-5690.

International Nickel Study Group. (2023). Nickel-Based Alloys in Pressure Equipment: A Global Market Analysis.

Thompson, L. K., & Davis, R. E. (2020). Welding Metallurgy of Nickel Alloys for Pressure Vessel Applications. Welding Journal, 99(5), 145-156.

European Committee for Standardization. (2021). EN 13445: Unfired Pressure Vessels - Part 2: Materials. CEN/TC 54.

Williams, P. D., & Brown, S. A. (2022). Long-Term Performance of Monel 400 in Seawater Desalination Plants. Desalination and Water Treatment, 210, 78-89.

Learn about our latest products and discounts through SMS or email