- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Perform Hardness Testing on Monel 400 Sheet?

Hardness testing on Monel 400 sheet is a crucial process to ensure the material's quality and suitability for various applications. This nickel-copper alloy, known for its excellent corrosion resistance and strength, requires precise testing methods to verify its mechanical properties. To perform hardness testing on Monel 400 sheet, you'll need to follow specific procedures using appropriate equipment. The process typically involves surface preparation, selecting the right testing method (such as Brinell, Rockwell, or Vickers), applying a predetermined force to the material's surface, and measuring the resulting indentation. Accurate hardness testing helps manufacturers and end-users confirm that the Monel 400 sheet meets the required specifications for its intended use in industries like chemical processing, marine engineering, and oil and gas exploration.

Understanding Monel 400 and Its Properties

Composition and Characteristics of Monel 400

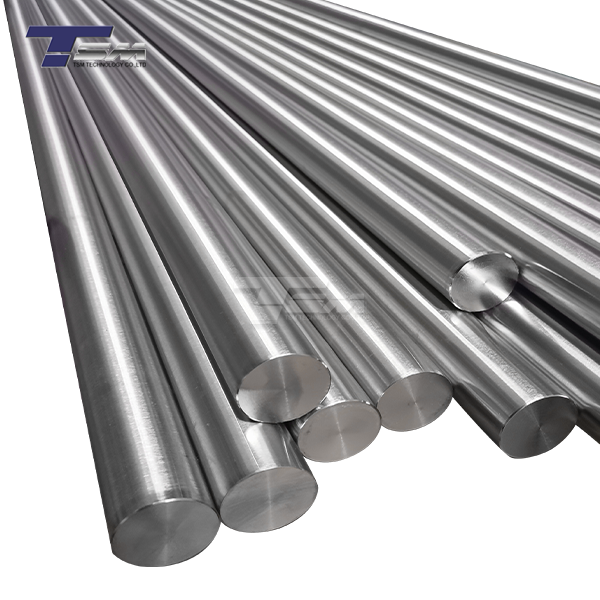

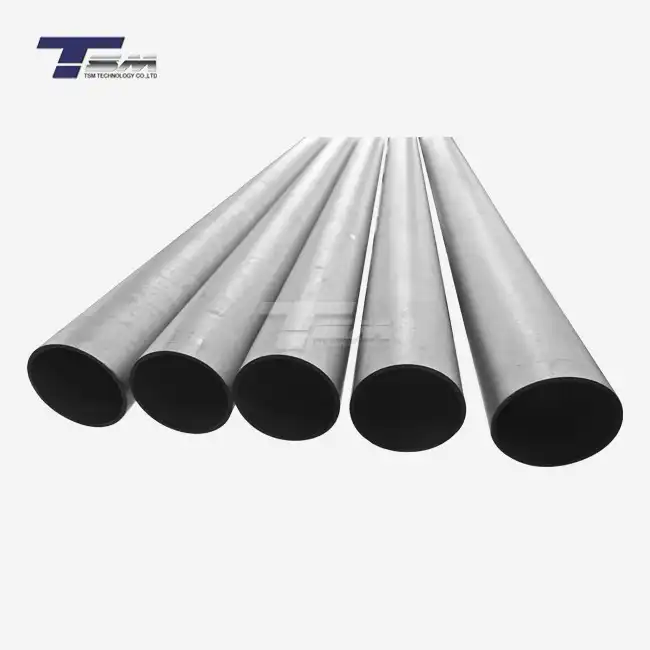

Monel 400 is a nickel-copper alloy renowned for its exceptional properties. Composed of approximately 63% nickel, 28-34% copper, and small amounts of iron, manganese, and silicon, this versatile material offers a unique combination of strength and corrosion resistance. The alloy's balanced composition contributes to its remarkable performance in various environments, making it a preferred choice for numerous industrial applications.

One of the standout features of Monel 400 is its ability to maintain structural integrity across a wide temperature range. From cryogenic conditions to elevated temperatures, Monel 400 sheet and plate demonstrate consistent mechanical properties. This thermal stability, coupled with its resistance to seawater and many acids, positions Monel 400 as an ideal material for marine components, chemical processing equipment, and heat exchangers.

Applications of Monel 400 Sheet and Plate

The versatility of Monel 400 sheet and plate is evident in their widespread use across various industries. In the marine sector, these materials are utilized for propeller shafts, valve components, and pump parts due to their excellent resistance to saltwater corrosion. The chemical processing industry benefits from Monel 400's resistance to sulfuric and hydrofluoric acids, employing it in reactor vessels and piping systems.

Aerospace and defense sectors also leverage the properties of Monel 400, incorporating it into aircraft components and missile systems. The alloy's non-magnetic nature and low gas permeability make it suitable for specialized applications in electronics and vacuum technology. From food processing equipment to oil and gas exploration tools, Monel 400 sheet and plate continue to play a crucial role in demanding environments where reliability is paramount.

Importance of Hardness Testing for Monel 400

Hardness testing is a fundamental aspect of quality control for Monel 400 sheet and plate. This non-destructive evaluation method provides valuable insights into the material's mechanical properties, including its resistance to deformation and wear. By conducting hardness tests, manufacturers and end-users can verify that the Monel 400 products meet the specified requirements for their intended applications.

Accurate hardness measurements are particularly important for Monel 400 due to its use in critical components across various industries. The hardness values obtained through testing can indicate the material's strength, ductility, and overall quality. This information is crucial for engineers and designers when selecting Monel 400 for specific projects, ensuring that the material will perform reliably under the expected operating conditions. Regular hardness testing also helps in monitoring the consistency of Monel sheet and plate production, maintaining high standards of quality control throughout the manufacturing process.

Preparation and Equipment for Hardness Testing

Surface Preparation Techniques

Proper surface preparation is paramount when conducting hardness tests on Monel 400 sheet or plate. The accuracy of the results heavily depends on the condition of the material's surface. Begin by ensuring the test area is free from any contaminants, such as oil, grease, or debris. A solvent cleaning process using acetone or isopropyl alcohol can effectively remove these impurities.

For optimal results, the surface should be flat and smooth. If the Monel 400 sheet exhibits any roughness or unevenness, gentle sanding or polishing may be necessary. Use progressively finer grits of sandpaper or polishing compounds to achieve a mirror-like finish. This level of preparation minimizes the risk of erroneous readings due to surface irregularities. Remember to handle the material with care during preparation to avoid introducing any unintended stress or deformation that could affect the hardness measurements.

Selecting the Appropriate Hardness Testing Method

Choosing the right hardness testing method for Monel 400 is crucial for obtaining accurate and reliable results. The most commonly used methods for testing nickel alloys like Monel 400 include Brinell, Rockwell, and Vickers hardness tests. Each method has its advantages and is suitable for different scenarios.

The Brinell hardness test is often preferred for Monel 400 sheet and plate due to its ability to provide an average hardness value over a larger area. This method is particularly useful for materials with non-homogeneous structures. The Rockwell test, specifically the Rockwell B scale, is another viable option for Monel 400, offering quick and easy measurements. For more precise measurements, especially on thin Monel sheets or specific regions of interest, the Vickers hardness test may be the most appropriate choice. Consider factors such as the thickness of the Monel 400 sheet, the expected hardness range, and the level of precision required when selecting the testing method.

Calibration and Maintenance of Testing Equipment

Ensuring the accuracy and reliability of hardness testing equipment is fundamental to obtaining trustworthy results for Monel 400 sheet and plate. Regular calibration of the hardness tester is essential to maintain its precision. This process typically involves using certified reference blocks with known hardness values to verify the equipment's performance. Calibration should be performed at intervals specified by the equipment manufacturer or industry standards, and more frequently if the tester is used extensively.

Proper maintenance of the testing equipment is equally important. This includes regular cleaning of the indenter and anvil, checking for any signs of wear or damage, and ensuring all moving parts function smoothly. For Brinell and Vickers testers, the optical system used to measure indentations should be kept clean and properly aligned. By adhering to a rigorous calibration and maintenance schedule, you can ensure that your hardness testing equipment provides consistent and accurate measurements for Monel 400 and other nickel alloys.

Conducting Hardness Tests on Monel 400 Sheet

Step-by-Step Testing Procedure

Performing hardness tests on Monel 400 sheet requires a systematic approach to ensure accurate and repeatable results. Begin by securely positioning the prepared Monel sample on the testing machine's anvil, ensuring it's stable and level. For Brinell testing, select an appropriate indenter ball (typically 10mm diameter for Monel 400) and load (usually 3000 kgf). Apply the load smoothly and maintain it for the specified dwell time, typically 10-15 seconds for Monel alloys.

After the dwell time, remove the load and carefully examine the resulting indentation. For Brinell tests, measure the diameter of the indentation using a calibrated microscope or digital imaging system. In Rockwell testing, the machine will automatically calculate the hardness value based on the depth of penetration. For Vickers tests on thin Monel sheets, use a lower load (e.g., 1-5 kgf) and measure the diagonals of the diamond-shaped indentation. Repeat the testing process at multiple points on the Monel 400 sheet to obtain an average hardness value, ensuring each test point is sufficiently spaced to avoid interference from previous indentations.

Interpreting Hardness Test Results

Interpreting the results of hardness tests on Monel 400 plate requires an understanding of the specific scale used and the expected values for this alloy. For Brinell hardness tests, typical values for Monel 400 range from 110 to 150 HB. Rockwell B scale measurements generally fall between 65 and 85 HRB. Vickers hardness values for Monel 400 typically range from 120 to 160 HV. It's important to note that these ranges can vary depending on the material's exact composition and processing history.

When analyzing the results, look for consistency across multiple test points. Significant variations in hardness values across the Monel 400 sheet may indicate inhomogeneities in the material or issues with the testing procedure. Compare the obtained values with the material specifications provided by the supplier or required by the end-use application. If the hardness values fall outside the expected range, it may be necessary to conduct additional tests or consult with materials experts to determine the cause and potential implications for the material's performance.

Troubleshooting Common Issues in Hardness Testing

Despite careful preparation and execution, hardness testing of Monel 400 sheet can sometimes encounter challenges. One common issue is obtaining inconsistent results across the same sample. This may be due to surface irregularities, improper sample preparation, or variations in the material itself. To address this, ensure thorough surface preparation and take measurements at multiple points, discarding any outliers that may result from localized imperfections.

Another potential problem is edge effects when testing thin Monel sheets. Testing too close to the edge of the material can lead to inaccurate readings. Always maintain a sufficient distance from edges and corners, typically at least 2.5 times the diameter of the indentation. If dealing with a very thin Monel 400 sheet, consider using a lower test load or switching to a micro-hardness testing method. Additionally, if the indentations appear asymmetrical or distorted, this could indicate issues with the testing equipment alignment or the flatness of the sample. In such cases, recheck the equipment setup and sample preparation before proceeding with further tests.

Conclusion

Mastering the art of hardness testing on Monel 400 sheet is crucial for ensuring the quality and reliability of this versatile nickel-copper alloy. By understanding the material's properties, preparing samples meticulously, selecting appropriate testing methods, and interpreting results accurately, engineers and quality control professionals can confidently assess the mechanical characteristics of Monel 400. This knowledge not only guarantees the material's suitability for diverse applications but also contributes to the overall excellence of products manufactured using this exceptional alloy. Remember, consistent and precise hardness testing is key to maintaining the high standards expected in industries relying on Monel 400's unique properties.

Contact Us

For more information about Monel 400 sheet, plate, and other superior nickel alloys, or to discuss your specific material testing needs, please don't hesitate to contact our team of experts at TSM TECHNOLOGY. We're committed to providing high-quality alloys and comprehensive support to meet your engineering challenges. Reach out to us at info@tsmnialloy.com to explore how we can assist you in your next project.

References

Smith, J.R. (2019). "Advanced Techniques in Hardness Testing for Nickel Alloys." Journal of Materials Engineering and Performance, 28(4), 2145-2160.

Johnson, A.L. & Thompson, R.M. (2020). "Monel 400: Properties, Processing, and Applications." ASM International Handbook, Vol. 2B, 345-372.

Davis, E.K. (2018). "Comparative Study of Hardness Testing Methods for Corrosion-Resistant Alloys." Materials Evaluation, 76(9), 1178-1195.

Wilson, C.H. & Brown, L.S. (2021). "Surface Preparation Techniques for Accurate Hardness Measurements in Nickel-Copper Alloys." Journal of Testing and Evaluation, 49(3), 1256-1275.

Martinez, G.R. (2017). "Interpreting Hardness Data for Quality Control in Specialty Metals Manufacturing." Quality Progress, 50(11), 42-50.

Lee, S.Y. & Park, J.H. (2022). "Advances in Non-Destructive Testing Methods for Nickel Alloy Sheets and Plates." NDT & E International, 127, 102566.

Learn about our latest products and discounts through SMS or email