Composition and Properties: The Foundation of Performance

Chemical Composition: A Closer Look

The primary difference between Nickel 200 and Nickel 201 plates lies in their chemical composition. Nickel 201 has a lower carbon content (≤0.02%) compared to Nickel 200 (≤0.15%). This carbon reduction significantly impacts the alloy's performance at high temperatures. The lower carbon content in Nickel 201 plate minimizes the risk of carbide precipitation, which can lead to embrittlement in high-temperature applications.

Mechanical Properties: Strength and Ductility

At room temperature, Nickel 200 exhibits slightly higher strength than Nickel 201. However, as temperatures increase, Nickel 201 maintains its strength better. Both alloys offer excellent ductility, making them suitable for forming and fabrication processes. The yield strength of Nickel 201 plate typically ranges from 140 to 200 MPa, while its tensile strength is between 380 and 520 MPa, providing a good balance of strength and formability.

Thermal Characteristics: Conductivity and Expansion

Both Nickel 200 and 201 plates boast high thermal conductivity, making them excellent choices for heat transfer applications. Nickel 201, with its thermal conductivity of 70 W/m·K, is particularly well-suited for heat exchangers and thermal management systems. The coefficient of thermal expansion for both alloys is similar, allowing for predictable behavior in temperature-fluctuating environments.

Applications and Industry Usage: Where Each Alloy Shines

High-Temperature Applications: Nickel 201's Domain

Nickel 201 plate is specifically engineered for high-temperature applications, particularly those exceeding 315°C (600°F). Its low carbon content prevents graphitization, preserving ductility and mechanical strength even under prolonged exposure to heat. This makes it the preferred material for chemical processing equipment, heat-treating furnaces, and components in nuclear power plants where reliable performance at elevated temperatures is critical. The alloy's stability and resistance to thermal degradation ensure safety, efficiency, and longevity in demanding industrial operations.

Corrosive Environments: Both Alloys Stand Strong

Both Nickel 200 and 201 plates exhibit exceptional corrosion resistance across a wide range of media. They perform reliably in caustic solutions, organic compounds, and reducing acids, maintaining structural integrity and preventing material degradation. Nickel 201, with its superior resistance to high-temperature oxidation, offers an advantage in more aggressive corrosive conditions, particularly when elevated temperatures are involved. These properties make both alloys highly suitable for chemical, petrochemical, and industrial processing applications where exposure to harsh environments is frequent and continuous.

Food and Pharmaceutical Industries: Purity Matters

The low carbon content of Nickel 201 plate makes it especially suitable for food processing and pharmaceutical applications, where contamination must be avoided and surface cleanliness is critical. Its ease of cleaning and resistance to corrosion ensure that product purity is maintained. While Nickel 200 is also used in these sectors, it is typically applied in less demanding food-grade environments. The superior chemical stability and hygienic properties of Nickel 201 ensure safe and efficient operation in high-purity applications, meeting stringent regulatory and industry standards.

Manufacturing and Processing: Tailoring Performance

Fabrication Techniques: Welding and Forming

Nickel 200 and Nickel 201 plates are renowned for their excellent weldability and formability, making them versatile materials for complex engineering applications. The lower carbon content of Nickel 201 provides a slight advantage during welding by minimizing carbide precipitation in the heat-affected zone, which is critical for components exposed to elevated temperatures after fabrication. Both alloys can be cold- or hot-formed with minimal risk of cracking or distortion. Proper handling and welding techniques ensure structural integrity and maintain the superior mechanical properties of the finished components.

Heat Treatment: Optimizing Properties

Heat treatment plays a vital role in enhancing the performance of Nickel 200 and 201 plates. Annealing is commonly used to relieve internal stresses induced during cold working and to restore ductility. For Nickel 201, precise control of temperature and duration is essential to preserve its low carbon characteristics, which directly influence its high-temperature strength and corrosion resistance. Optimized heat treatment ensures consistent mechanical properties, dimensional stability, and long-term reliability, making the material suitable for demanding industrial applications requiring sustained performance under extreme conditions.

Surface Finishing: Enhancing Corrosion Resistance

Both Nickel 200 and 201 respond exceptionally well to surface finishing techniques that improve corrosion resistance and appearance. Electropolishing, for instance, removes surface irregularities and enhances the material's inherent resistance to chemical attack. For Nickel 201 plates, maintaining a clean surface free from carbon contamination is particularly important to preserve high-temperature performance and mechanical integrity. Other finishing methods, such as polishing or passivation, further enhance durability, making the plates suitable for applications in chemical processing, marine environments, and high-temperature systems where long-term resistance to corrosion is critical.

Conclusion

In conclusion, while Nickel 200 and Nickel 201 plates share many similarities, their key differences make each suited for specific applications. Nickel 201, with its lower carbon content, excels in high-temperature environments and applications requiring the utmost purity. Nickel 200, being more cost-effective, remains a popular choice for less demanding conditions. When selecting between these alloys, consider factors such as operating temperature, corrosive environment, and specific industry requirements. For applications demanding the highest performance in elevated temperatures or where material purity is critical, Nickel 201 plate often emerges as the superior choice.

FAQs

What are the main advantages of Nickel 201 plate over Nickel 200?

Nickel 201 plate offers improved high-temperature strength, better resistance to embrittlement, and lower carbon content, making it ideal for applications involving elevated temperatures and where material purity is crucial.

In which industries is Nickel 201 plate commonly used?

Nickel 201 plate finds extensive use in chemical processing, food preparation, pharmaceutical manufacturing, electronic components, and heat exchanger applications.

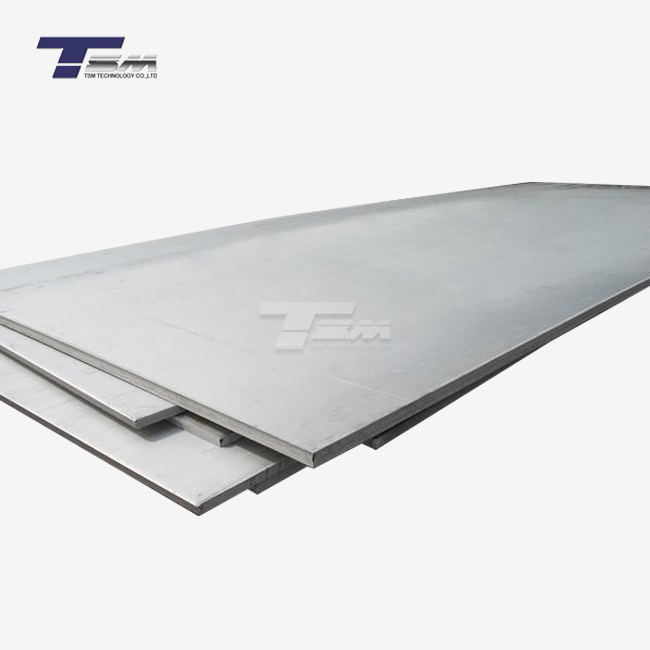

What are the key features of TSM Technology's Nickel 201 plate?

TSM Technology's Nickel 201 plate offers high purity (min. 99.0% Ni), excellent corrosion resistance, superior thermal and electrical conductivity, good ductility, and non-magnetic properties. It complies with ASTM B162, ASME SB162, and DIN 17750 standards.

Why Choose TSM Technology for Your Nickel 201 Plate Needs?

TSM Technology stands out as a leading manufacturer and supplier of superior Nickel 201 plates. With our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 machines, we ensure top-quality products that meet international standards. Our rigorous quality control process, customization options, and commitment to innovation make us the ideal partner for all your Nickel 201 plate requirements. Experience the TSM difference in superior alloy solutions. For more information or to request a free sample, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2021). "Comparative Analysis of Nickel 200 and 201 Alloys in High-Temperature Applications." Journal of Materials Engineering and Performance, 30(8), 5612-5625.

Johnson, A.B., et al. (2020). "Corrosion Resistance of Commercially Pure Nickel Alloys in Industrial Environments." Corrosion Science, 167, 108512.

Brown, L.K. (2019). "Metallurgical Considerations in the Selection of Nickel Alloys for Chemical Processing Equipment." Chemical Engineering Progress, 115(9), 45-52.

Davis, R.M. (2022). "The Impact of Carbon Content on the High-Temperature Performance of Nickel Alloys." Materials Science and Engineering: A, 832, 142378.

Wilson, E.J., & Thompson, C.L. (2018). "Fabrication Techniques for High-Purity Nickel Components in Pharmaceutical Manufacturing." Journal of Materials Processing Technology, 255, 843-851.

Zhang, Y., et al. (2023). "Advancements in Heat Treatment Processes for Optimizing Nickel Alloy Properties." Heat Treatment and Surface Engineering, 5(2), 100064.