- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Nickel 201 Tube Mechanical Testing and Quality Assurance

Nickel 201 tube mechanical testing and quality assurance are crucial processes in ensuring the reliability and performance of this versatile alloy. As a commercially pure wrought nickel alloy, Nickel 201 offers exceptional corrosion resistance, high thermal and electrical conductivity, and superior mechanical properties. Rigorous testing procedures and stringent quality control measures are implemented to guarantee that Nickel 201 tubes meet industry standards and customer specifications. This article delves into the various aspects of mechanical testing and quality assurance for Nickel 201 tubes, highlighting their importance in maintaining product integrity and performance across diverse applications.

Comprehensive Mechanical Testing Procedures for Nickel 201 Tubes

Tensile Strength Testing

Tensile strength testing is a fundamental mechanical test performed on Nickel 201 tubes. This test evaluates the material's ability to withstand longitudinal stress and determines its ultimate tensile strength, yield strength, and elongation. Nickel 201 tubes typically exhibit excellent tensile properties, with a minimum tensile strength of 345 MPa (50 ksi) and a yield strength of 105 MPa (15 ksi). The elongation percentage, usually around 35%, demonstrates the material's ductility and formability.

Hardness Testing

Hardness testing is another crucial aspect of Nickel 201 tube mechanical evaluation. The Brinell or Rockwell hardness scales are commonly used to measure the material's resistance to indentation. Nickel 201 tubes generally have a Brinell hardness range of 90-150 HB, which contributes to their wear resistance and durability in various applications. Regular hardness testing ensures consistency in material properties across different production batches.

Flattening and Flaring Tests

Flattening and flaring tests are specific to tubular products like Nickel 201 tubes. The flattening test involves compressing a section of the tube between two flat plates until the distance between the plates reaches a specified value. This test assesses the tube's ductility and its ability to withstand deformation without cracking. The flaring test, on the other hand, evaluates the tube's ability to undergo expansion at its end without failure. These tests are crucial for applications where the tubes may be subjected to bending or forming operations.

Non-Destructive Testing and Quality Control Measures

Ultrasonic Testing

Ultrasonic testing is a non-destructive method widely used in the quality control of Nickel 201 tubes. This technique employs high-frequency sound waves to detect internal defects, such as inclusions, voids, or cracks, that may not be visible on the surface. Ultrasonic testing is particularly valuable for seamless Nickel 201 tubes, ensuring the integrity of the tube wall throughout its length. The high sensitivity of this method allows for the detection of even minute flaws, contributing to the overall reliability of the product.

Eddy Current Testing

Eddy current testing is another non-destructive technique used in the quality assurance of Nickel 201 tubes. This method is especially effective in detecting surface and near-surface defects, as well as variations in wall thickness. By inducing electromagnetic fields in the material, eddy current testing can identify discontinuities that may affect the tube's performance. This technique is particularly useful for inspecting welded Nickel 201 tubes, ensuring the integrity of the weld seam and the surrounding heat-affected zone.

Dimensional Inspection and Tolerances

Precise dimensional control is essential for Nickel 201 tubes to meet specific application requirements. Rigorous dimensional inspections are conducted to verify compliance with industry standards such as ASTM B161, B725, and B775. These inspections include measurements of outside diameter, wall thickness, and length. Typical tolerances for Nickel 201 tubes include ±0.13 mm (±0.005 in) for outside diameter and ±10% for wall thickness. Ensuring dimensional accuracy is crucial for applications in heat exchangers, chemical processing equipment, and other precision engineering fields.

Chemical Composition Analysis and Corrosion Resistance Testing

Spectrographic Analysis

Spectrographic analysis is a key component of quality assurance for Nickel 201 tubes. This technique determines the precise chemical composition of the alloy, ensuring it meets the specified requirements. Nickel 201 typically contains a minimum of 99% nickel, with trace amounts of carbon, manganese, iron, silicon, and copper. Accurate chemical analysis is crucial as even small variations in composition can significantly affect the material's properties and performance in corrosive environments.

Intergranular Corrosion Testing

Intergranular corrosion testing is performed to evaluate the resistance of Nickel 201 tubes to grain boundary attack in corrosive media. This test is particularly important for applications in chemical processing and marine environments. Samples of Nickel 201 tubes are exposed to specific corrosive solutions for predetermined periods, after which they are examined for signs of intergranular attack. The absence of significant corrosion indicates the material's suitability for use in harsh chemical environments.

Stress Corrosion Cracking Resistance

Stress corrosion cracking (SCC) resistance is a critical property for Nickel 201 tubes used in high-stress applications exposed to corrosive media. Testing for SCC resistance involves subjecting stressed samples to specific corrosive environments and monitoring for crack initiation and propagation. Nickel 201's excellent resistance to SCC in various media, including caustic solutions and chloride-containing environments, makes it a preferred choice for applications in the chemical processing and energy sectors.

Conclusion

The comprehensive mechanical testing and quality assurance processes for Nickel 201 tubes are essential in maintaining the high standards required for critical applications across various industries. From tensile strength testing to non-destructive evaluations and corrosion resistance assessments, each step contributes to ensuring the reliability, durability, and performance of Nickel 201 tubing. By adhering to rigorous testing protocols and quality control measures, manufacturers can provide customers with Nickel 201 tubes that consistently meet or exceed industry standards, supporting the material's reputation for excellence in challenging environments.

FAQs

What are the key mechanical properties of Nickel 201 tubes?

Nickel 201 tubes exhibit excellent tensile strength (minimum 345 MPa), good yield strength (105 MPa), and high elongation (around 35%). They also have a Brinell hardness range of 90-150 HB.

How is the corrosion resistance of Nickel 201 tubes tested?

Corrosion resistance is evaluated through intergranular corrosion testing and stress corrosion cracking resistance tests, exposing samples to specific corrosive environments.

What non-destructive testing methods are used for Nickel 201 tubes?

Ultrasonic testing and eddy current testing are commonly used non-destructive methods for inspecting Nickel 201 tubes for internal and surface defects.

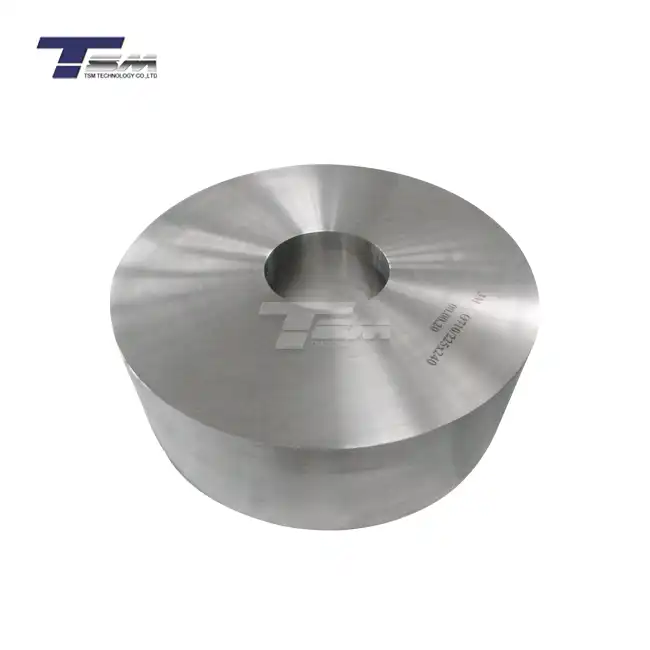

Quality Assurance of Nickel 201 Tubes | TSM TECHNOLOGY

At TSM Technology, we pride ourselves on delivering top-quality Nickel 201 tubes that exceed industry standards. Our rigorous quality assurance process encompasses comprehensive mechanical testing, non-destructive evaluations, and stringent chemical composition analysis. With our state-of-the-art testing facilities and experienced team, we ensure that every Nickel 201 tube meets the highest quality benchmarks. For premium Nickel 201 tubing solutions tailored to your specific needs, contact our experts at info@tsmnialloy.com.

References

ASTM International. (2020). "Standard Specification for Nickel Seamless Pipe and Tube." ASTM B161-20.

ASM International. (2018). "Nickel and Nickel Alloys: Properties and Performance." ASM Handbook, Volume 2B.

Rebak, R. B. (2019). "Corrosion of Non-Ferrous Alloys. I. Nickel, Cobalt, Copper, Zirconium and Titanium-Based Alloys." Shreir's Corrosion, 4th Edition.

Davis, J. R. (2017). "Nickel, Cobalt, and Their Alloys." ASM Specialty Handbook.

Special Metals Corporation. (2021). "Nickel 200 & 201 Technical Data Sheet."

ISO. (2018). "Metallic materials — Tube — Flattening test." ISO 8492:2018.

Learn about our latest products and discounts through SMS or email