- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Hydrostatic Testing Procedures for Nickel 201 Tubes

Hydrostatic testing is a critical quality assurance procedure for Nickel 201 tubes, ensuring their integrity and reliability in demanding applications. This process involves filling the tubes with water or another liquid and pressurizing them to verify their strength and detect any leaks or defects. For Nickel 201 tubes, known for their excellent corrosion resistance and mechanical properties, proper hydrostatic testing is essential to maintain their high performance in various industries such as aerospace, chemical processing, and energy production.

Understanding Nickel 201 Tubes and Their Properties

Composition and Characteristics of Nickel 201

Nickel 201 is a low-carbon, commercially pure nickel alloy containing a minimum of 99% nickel, which accounts for its excellent corrosion and oxidation resistance. This composition makes the alloy particularly stable in reducing and neutral environments, including caustic soda and alkaline solutions. Additionally, Nickel 201 exhibits superior thermal and electrical conductivity, allowing efficient heat and current transfer. Its resistance to scaling and chemical degradation at elevated temperatures ensures dependable performance in chemical, petrochemical, and electronic industries.

Mechanical Properties of Nickel 201 Tubes

Nickel 201 tubes are known for their outstanding mechanical strength, ductility, and toughness, which make them ideal for high-stress and high-temperature applications. The alloy maintains structural integrity even under cyclic loading or vibration, offering long service life in harsh operating conditions. Its low carbon content prevents carbide precipitation, eliminating the risk of embrittlement during prolonged heat exposure. As a result, Nickel 201 tubes combine flexibility, durability, and resilience, ensuring consistent performance in both ambient and elevated temperature environments.

Applications Requiring Hydrostatic Testing

Hydrostatic testing is a vital step in verifying the integrity of Nickel 201 tubes used in critical service applications. Industries such as power generation, chemical processing, and heat exchange rely on these tests to ensure the tubes can safely withstand high internal pressures without leakage or deformation. During testing, tubes are filled with water or another non-compressible fluid and subjected to controlled pressure conditions. This rigorous assessment guarantees reliability, safety, and compliance with international standards before the tubes are deployed in demanding operational systems.

Preparing for Hydrostatic Testing of Nickel 201 Tubes

Equipment and Materials Needed

Conducting hydrostatic testing on Nickel 201 tubes requires precise and reliable equipment to ensure accuracy and safety. The essential tools include a hydrostatic test pump capable of generating controlled pressure, calibrated pressure gauges for accurate monitoring, and end caps or sealing plugs to secure both tube ends. A clean water source is typically used as the testing medium. Additionally, operators must wear appropriate personal protective equipment such as gloves, goggles, and face shields. All instruments should be inspected and verified for proper calibration before testing begins.

Safety Precautions and Considerations

Ensuring safety during hydrostatic testing is critical due to the involvement of high pressures that can pose significant risks if not properly managed. The testing area should be clearly marked and restricted to authorized personnel only. All staff involved must be thoroughly trained in handling pressure systems and emergency shutdown procedures. Pressure should be increased gradually while continuously monitoring for abnormalities. Adhering to industry standards, such as ASME or ASTM guidelines, minimizes hazards and ensures both personnel safety and reliable test outcomes.

Pre-Test Inspection and Preparation

Before starting hydrostatic testing, a detailed inspection of Nickel 201 tubes must be performed to identify any dents, cracks, or surface irregularities. Cleaning the tubes using appropriate solvents or water removes contaminants that could affect pressure readings. The test setup should ensure tight, leak-free connections with properly fitted seals. It is equally important to eliminate all trapped air within the system, as air pockets can distort pressure readings and compromise accuracy. This meticulous preparation ensures dependable, reproducible test results and verifies tube integrity before operational use.

Conducting the Hydrostatic Test on Nickel 201 Tubes

Step-by-Step Testing Procedure

Begin by filling the Nickel 201 tube with water, ensuring all air is expelled. Gradually increase the pressure to the specified test pressure, which is typically 1.5 times the design pressure of the tube. Maintain this pressure for a predetermined period, usually a minimum of 10 minutes. During this time, carefully inspect the tube for any signs of leakage, deformation, or failure.

Monitoring and Recording Test Results

Throughout the test, continuously monitor the pressure gauge for any fluctuations. Record the initial pressure, test duration, and any observations made during the test. Pay close attention to any pressure drops, which could indicate a leak. After the test period, slowly release the pressure and inspect the tube for any permanent deformation or damage.

Interpreting Test Results and Quality Assurance

A successful hydrostatic test will show no leaks, no permanent deformation, and no significant pressure drop during the test period. Any deviation from these criteria may indicate a defect in the Nickel 201 tube. Thoroughly document all test results, including pass/fail status, for quality assurance purposes. These records are essential for maintaining traceability and ensuring the reliability of the tubes in their intended applications.

Conclusion

Hydrostatic testing is an indispensable process in ensuring the quality and reliability of Nickel 201 tubes. By following proper testing procedures and adhering to industry standards, manufacturers and end-users can confidently deploy these high-performance tubes in critical applications. The exceptional properties of Nickel 201, combined with rigorous quality control measures like hydrostatic testing, contribute to its widespread use in industries requiring superior corrosion resistance and mechanical strength.

FAQs

What pressure should be used for the hydrostatic testing of Nickel 201 tubes?

Typically, the test pressure is 1.5 times the design pressure of the tube.

How long should a hydrostatic test be conducted?

The standard test duration is usually a minimum of 10 minutes, but may vary based on specific industry standards or client requirements.

Can hydrostatic testing be performed on welded Nickel 201 tubes?

Yes, hydrostatic testing is crucial for both seamless and welded Nickel 201 tubes to ensure the integrity of the entire structure, including weld joints.

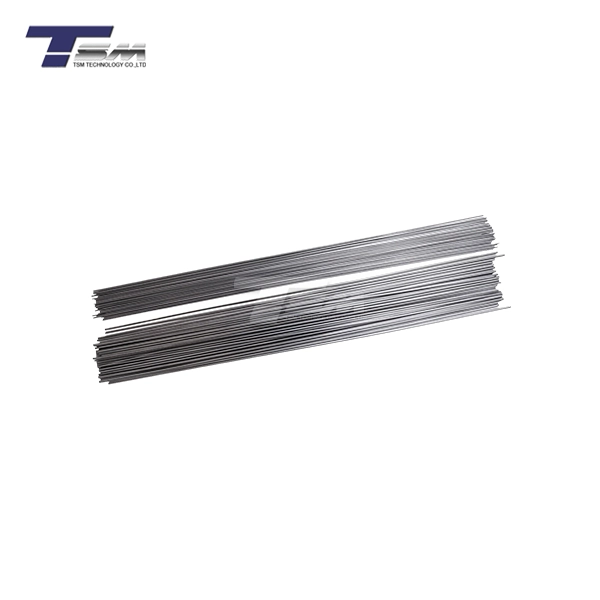

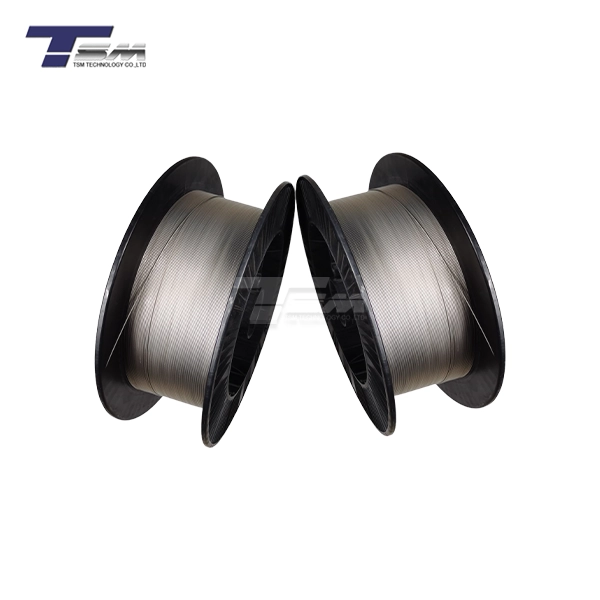

Choose TSM TECHNOLOGY for Your Nickel 201 Tube Needs

At TSM TECHNOLOGY, we specialize in providing high-quality Nickel 201 tubes that meet rigorous industry standards. Our state-of-the-art hydrostatic testing facilities ensure the reliability and performance of every tube we produce. With our extensive experience and commitment to quality, we offer customized solutions to meet your specific requirements. For superior Nickel 201 tubes and expert technical support, contact us at info@tsmnialloy.com. Trust TSM TECHNOLOGY for all your high-performance alloy needs.

References

ASTM International. (2020). "Standard Specification for Nickel Seamless Pipe and Tube," ASTM B161-20.

American Society of Mechanical Engineers. (2019). "ASME Boiler and Pressure Vessel Code, Section VIII: Rules for Construction of Pressure Vessels."

Nickel Institute. (2018). "Nickel Alloys in the Chemical Process Industry," Technical Series No. 10078.

ASM International. (2017). "ASM Handbook, Volume 13B: Corrosion: Materials."

Society of Automotive Engineers. (2016). "AMS 4549: Nickel Alloy, Corrosion and Heat Resistant, Seamless Tube."

International Organization for Standardization. (2015). "ISO 4952:2015 - Steel tubes for precision applications — Technical delivery conditions."

Learn about our latest products and discounts through SMS or email