- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Nickel Alloys: Breaking Down the Elements

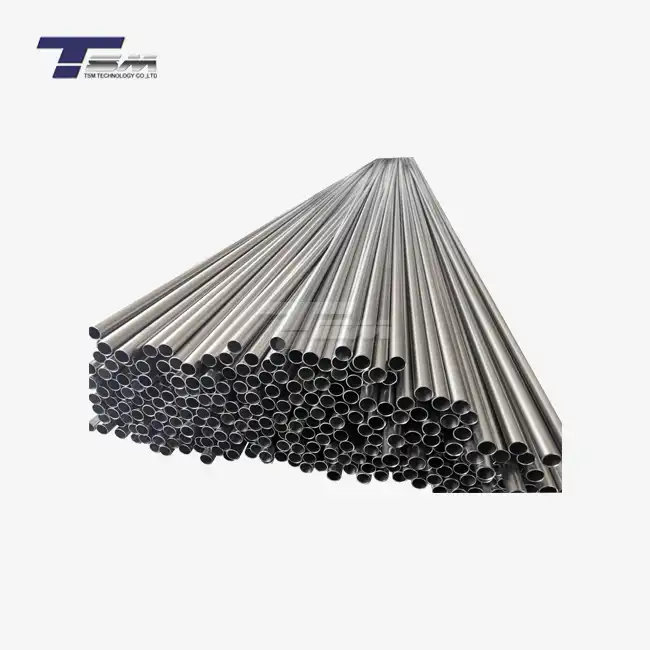

What makes nickel alloys so exceptional in the world of engineering and manufacturing? The answer lies in their elemental composition - a harmonious blend of metals that creates materials with unparalleled strength, corrosion resistance, and versatility. Nickel alloys, such as Monel, Inconel, Incoloy, and Hastelloy, are engineered by combining nickel with other elements like chromium, molybdenum, and iron. This fusion results in materials that can withstand extreme temperatures, resist oxidation, and endure harsh chemical environments. At TSM Technology Co., Ltd., we specialize in crafting these superior alloys, ensuring each product meets rigorous quality standards to serve precision engineering and machine shops globally.

The Core Elements of Nickel Alloys

Nickel alloys are celebrated for their robustness, but what exactly goes into their creation? Understanding the elemental makeup of these materials reveals why they are indispensable in industries ranging from aerospace to chemical processing.

Nickel: The Foundation of Strength

At the heart of every nickel alloy lies its namesake - nickel. This silvery-white metal is prized for its ability to resist corrosion and maintain structural integrity under extreme conditions. Nickel's inherent ductility allows it to be shaped into various forms, from pipes to sheets, without compromising its strength. Its capacity to form a protective oxide layer when exposed to air makes it a natural shield against rust and degradation, a quality that is amplified when combined with other elements.

Chromium: The Corrosion-Resistant Champion

Chromium is a pivotal addition to many nickel alloys, enhancing their ability to fend off corrosion. This element forms a passive layer of chromium oxide on the surface of the alloy, acting as a barrier against aggressive environments, such as those involving acids or saltwater. In alloys like Inconel, chromium's presence ensures longevity and reliability, making them ideal for applications where exposure to harsh elements is inevitable.

Molybdenum: The Heat and Wear Defender

Molybdenum brings another layer of resilience to nickel alloys, particularly in terms of heat and wear resistance. This element bolsters the alloy's ability to endure high temperatures without deforming, a critical trait for components in jet engines or industrial furnaces. Molybdenum also enhances resistance to pitting and crevice corrosion, making alloys like Hastelloy a preferred choice in chemical processing plants where exposure to corrosive substances is routine.

Unique Properties of Nickel Alloy Variants

Not all nickel alloys are created equal - each variant is meticulously engineered to excel in specific applications. By tweaking the elemental composition, manufacturers can tailor the properties of these materials to meet the exacting demands of diverse industries.

Monel

Monel, a nickel-copper alloy, is renowned for its exceptional resistance to seawater and acidic environments. With a composition that typically includes around 67% nickel and 30% copper, Monel exhibits remarkable strength and durability, even in sub-zero temperatures. Its ability to resist stress-corrosion cracking makes it a staple in marine engineering, where components must withstand the relentless assault of saltwater and humidity.

Inconel

Inconel alloys, enriched with chromium and iron, are designed to thrive in extreme heat. These materials maintain their mechanical properties at temperatures exceeding 1,000°C, making them indispensable in aerospace and power generation. The addition of niobium in certain Inconel variants further enhances creep resistance, ensuring that components like turbine blades remain intact under prolonged stress and thermal exposure.

Hastelloy

Hastelloy stands out for its unparalleled resistance to aggressive chemicals, thanks to its high molybdenum and chromium content. This nickel alloy is engineered to withstand acids, chlorides, and other corrosive substances that would degrade lesser materials. Its versatility makes it a go-to choice for chemical processing equipment, where reliability in the face of caustic environments is non-negotiable.

Applications and Innovations in Nickel Alloys

The unique properties of nickel alloys have paved the way for groundbreaking applications across a multitude of sectors. As technology advances, so too does the development of these materials, pushing the boundaries of what is possible in engineering and manufacturing.

Aerospace

In the aerospace industry, nickel alloys are the unsung heroes behind jet engines, exhaust systems, and airframes. Their ability to endure extreme temperatures and resist oxidation ensures that aircraft can operate safely and efficiently, even at altitudes where conditions are unforgiving. Inconel, with its high-temperature prowess, is a prime example of a nickel alloy that has revolutionized aerospace engineering, enabling the creation of lighter, more fuel-efficient engines.

Chemical Processing

Chemical processing plants rely on nickel alloys to handle substances that would corrode or erode most other materials. Hastelloy, with its formidable resistance to acids and chlorides, is often used in reactors, valves, and piping systems. This durability translates to reduced maintenance costs and enhanced safety, as equipment can operate reliably in environments where failure is not an option.

Energy Sector

The energy sector, particularly in oil and gas exploration, demands materials that can withstand the harsh conditions of deep-sea drilling and high-pressure environments. Nickel alloys like Monel and Incoloy are integral to the construction of offshore platforms, pipelines, and refinery equipment. Their resistance to corrosion and stress ensures that energy production remains uninterrupted, even in the most challenging settings. Innovations in alloy development continue to enhance efficiency, with new compositions being explored to meet the evolving needs of renewable energy technologies.

Conclusion

Nickel alloys are a testament to the power of elemental synergy, blending metals like nickel, chromium, and molybdenum to create materials that defy the limits of traditional engineering. Their ability to resist corrosion, endure extreme temperatures, and withstand harsh chemicals makes them indispensable across a wide range of industries. By understanding the elemental composition and unique properties of these alloys, businesses can make informed decisions about the materials they use, ensuring longevity and performance in even the most demanding applications. At TSM Technology Co., Ltd., we pride ourselves on delivering superior alloys that drive innovation and reliability worldwide.

Contact Us

For more information about our superior nickel alloy products and how they can benefit your projects, please don't hesitate to reach out to us at info@tsmnialloy.com. At TSM TECHNOLOGY, we're committed to providing high-quality nickel alloys and expert support to meet your specific

References

Smith, J. A. (2020). Metallurgy of Nickel Alloys: Principles and Applications. New York: Industrial Press.

Davis, R. H. (2018). High-Performance Alloys in Extreme Environments. London: Elsevier.

Patel, K. M. (2019). Corrosion Resistance of Nickel-Based Materials. Chicago: ASM International.

Thompson, L. E. (2021). Advanced Materials in Aerospace Engineering. Boston: McGraw-Hill.

Nguyen, T. V. (2022). Chemical Processing with Nickel Alloys. Houston: Gulf Publishing Company.

Lee, S. H. (2023). Innovations in Nickel Alloy Development. Singapore: Springer Nature.

Learn about our latest products and discounts through SMS or email