- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Electropolishing Nickel 201 Sheet: Benefits for Corrosion Resistance

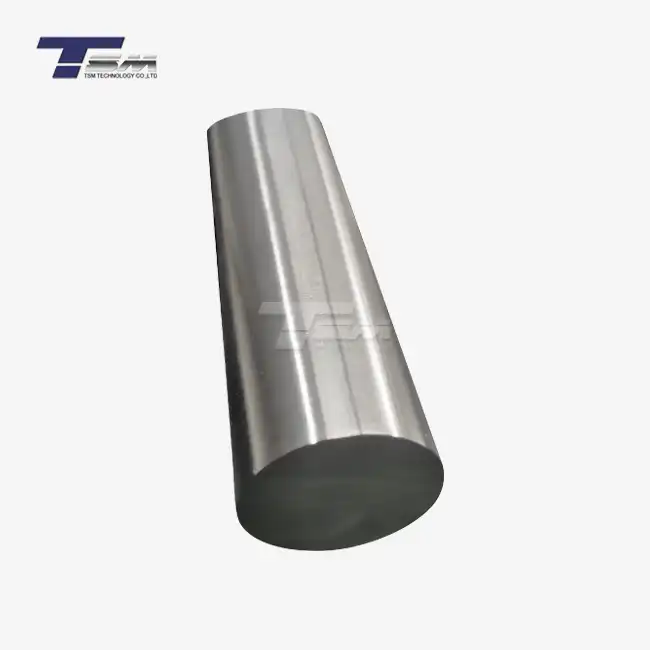

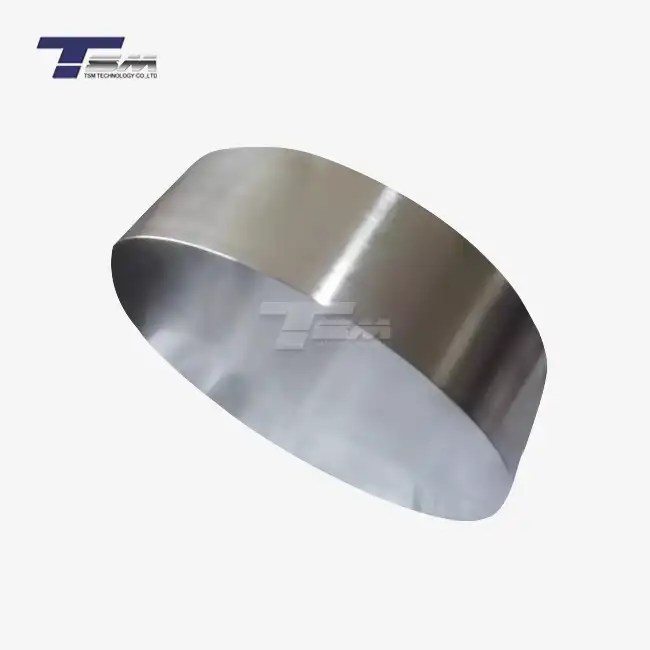

Electropolishing a Nickel 201 sheet delivers a myriad of advantages, particularly when it comes to bolstering corrosion resistance. This electrochemical process smooths the surface of the metal, eliminating microscopic imperfections and contaminants that could otherwise serve as initiation points for corrosion. By refining the surface, electropolishing enhances the alloy's innate ability to withstand harsh environments, including exposure to caustic substances and extreme temperatures. The result is a Nickel 201 sheet with a pristine, passive layer that significantly reduces the risk of oxidation and degradation. This makes it an ideal choice for industries demanding uncompromised durability, such as chemical processing, aerospace, and marine engineering, ensuring longevity and reliability in critical applications.

Unveiling the Power of Electropolishing for Nickel 201 Alloys

The Science Behind Electropolishing

Electropolishing is far more than a superficial treatment; it's a sophisticated electrochemical procedure that refines the surface of a Nickel 201 sheet at a microscopic level. During this process, the metal is submerged in an electrolytic bath, where it acts as the anode. A controlled current is applied, selectively dissolving surface material, particularly from peaks and protrusions. This meticulous removal of material smooths out irregularities, eradicates embedded impurities, and leaves behind a lustrous, uniform surface. For Nickel 201 alloys, renowned for their low carbon content and exceptional resistance to caustic environments, this process amplifies their natural protective qualities, creating a surface that is not only aesthetically pleasing but also functionally superior in resisting corrosive attacks.

How Electropolishing Enhances Corrosion Resistance?

The corrosion resistance of a Nickel 201 plate is inherently impressive, thanks to its high nickel content, which forms a stable oxide layer when exposed to air. Electropolishing takes this resilience a step further by optimizing the surface topography. By eliminating micro-crevices, burrs, and other surface defects, the process minimizes sites where corrosive agents, such as chlorides or acids, could initiate degradation. Additionally, electropolishing enriches the surface with chromium and nickel, enhancing the formation of a robust passive layer. This fortified barrier is particularly effective in environments prone to pitting and crevice corrosion, ensuring that components crafted from Nickel 201 alloys maintain their integrity over extended periods, even under relentless exposure to aggressive conditions.

Industries Benefiting from Electropolished Nickel Alloys

The advantages of electropolishing Nickel 201 sheets are not confined to a single sector; they resonate across a diverse array of industries. In chemical processing, where exposure to caustic solutions is routine, electropolished Nickel 201 components resist degradation, ensuring operational continuity. Aerospace applications, demanding materials that endure extreme temperatures and oxidative stress, find these alloys indispensable. Marine engineering, too, benefits immensely, as electropolished Nickel 201 plates withstand the relentless assault of saltwater without succumbing to corrosion. Beyond these, sectors like pharmaceuticals and food processing value the hygienic, easy-to-clean surfaces that electropolishing delivers, underscoring the versatility and indispensability of this treatment in precision engineering and beyond.

Why Nickel 201 Stands Out Among Special Metals?

Unique Properties of Nickel 201 Alloys

Nickel 201, a commercially pure wrought nickel alloy, distinguishes itself with a suite of remarkable properties that make it a preferred material in demanding applications. Its low carbon content - capped at 0.02% - minimizes the risk of carbide precipitation during welding, preserving its corrosion resistance in high-temperature environments. This alloy excels in resisting alkalis, acids, and dry gases, making it a stalwart in corrosive settings. A Nickel 201 sheet also boasts commendable thermal and electrical conductivity, alongside ductility that facilitates intricate fabrication. These attributes, combined with its ability to maintain structural integrity across a wide temperature spectrum, position Nickel 201 as a paragon among special metals, particularly when enhanced through advanced surface treatments like electropolishing.

Comparing Nickel 201 to Other Nickel-Based Alloys

While the family of nickel-based alloys - such as Monel, Inconel, and Hastelloy - offers a broad spectrum of performance characteristics, Nickel 201 carves out a unique niche. Unlike Monel, which incorporates copper for enhanced resistance to seawater, Nickel 201 prioritizes purity, delivering unparalleled performance in alkaline environments. Inconel, celebrated for its high-temperature strength, contrasts with Nickel 201's focus on corrosion resistance in reducing conditions. Hastelloy, with its molybdenum content, excels in acidic environments, whereas a Nickel 201 plate shines in caustic and neutral settings. This comparative analysis underscores the importance of selecting the right alloy for specific applications, with Nickel 201 often emerging as the optimal choice for projects requiring uncompromised resistance to alkaline corrosion.

The Role of Purity in Performance

The exceptional performance of Nickel 201 alloys is inextricably linked to their purity. With a nickel content exceeding 99%, these alloys minimize the presence of impurities that could compromise their corrosion resistance. This purity ensures the formation of a uniform, adherent oxide layer, which acts as a bulwark against environmental degradation. In applications where a Nickel 201 sheet is exposed to caustic soda, potash, or other alkaline substances, this purity translates into longevity and reliability. Electropolishing further enhances this advantage by removing surface contaminants and irregularities, ensuring that the alloy's inherent strengths are fully realized. This synergy between material purity and advanced surface treatment underscores why Nickel 201 remains a cornerstone in precision engineering.

Practical Applications and Long-Term Benefits of Electropolished Nickel 201

Real-World Applications of Nickel 201 Sheets

The versatility of a Nickel 201 sheet, particularly when electropolished, manifests in its widespread adoption across critical industries. In chemical processing, these sheets are integral to equipment like reactors and storage tanks, where they resist the corrosive effects of alkalis and acids. Aerospace engineers leverage electropolished Nickel 201 plates in components exposed to oxidative stress, valuing their ability to maintain integrity at elevated temperatures. Marine applications, such as offshore platforms and shipbuilding, rely on these alloys to combat the relentless corrosion induced by seawater. Beyond these, the pharmaceutical and food processing sectors utilize electropolished Nickel 201 for its hygienic properties, ensuring compliance with stringent cleanliness standards. These applications highlight the alloy's adaptability and enduring relevance.

Longevity and Cost-Effectiveness

Investing in electropolished Nickel 201 sheets yields dividends in the form of longevity and cost-effectiveness. The enhanced corrosion resistance imparted by electropolishing extends the service life of components, reducing the frequency of replacements and maintenance. This durability is particularly valuable in industries where downtime translates into significant financial losses, such as chemical processing and aerospace. Moreover, the smooth, electropolished surface minimizes the adhesion of contaminants, facilitating easier cleaning and reducing operational costs. While the initial investment in high-quality Nickel 201 plates and electropolishing may be higher than alternatives, the long-term savings in maintenance, replacements, and operational efficiency render it a prudent choice for discerning engineers and procurement specialists.

Sustainability and Environmental Considerations

In an era where sustainability is paramount, electropolished Nickel 201 alloys offer compelling environmental benefits. Their extended lifespan reduces the need for frequent material extraction and processing, conserving natural resources and minimizing waste. The smooth, electropolished surface also enhances energy efficiency in applications like heat exchangers, where reduced fouling translates into lower energy consumption. Additionally, Nickel 201's recyclability ensures that end-of-life components can be repurposed, aligning with circular economy principles. By choosing electropolished Nickel 201 sheets, industries not only enhance performance but also contribute to a more sustainable future, balancing operational excellence with environmental stewardship.

Conclusion

Electropolishing Nickel 201 sheets unlocks a host of benefits, from unparalleled corrosion resistance to enhanced longevity and sustainability. This advanced treatment amplifies the alloy's natural strengths, making it an indispensable material across industries like chemical processing, aerospace, and marine engineering. By investing in electropolished Nickel 201, businesses gain a competitive edge through reduced maintenance, improved efficiency, and environmental responsibility. The synergy of purity, performance, and surface refinement positions Nickel 201 as a cornerstone of precision engineering, delivering value that endures.

Contact Us

Ready to elevate your projects with superior alloys? Contact TSM TECHNOLOGY at info@tsmnialloy.com to explore our range of Nickel 201 sheets and discover how we can support your needs with quality and innovation.

References

ASM International, Nickel, Cobalt, and Their Alloys, Materials Park, OH, 2000.

International Nickel Study Group, Nickel Alloys in Corrosive Environments, Brussels, 2015.

NACE International, Corrosion Resistance of Nickel and Nickel Alloys, Houston, TX, 2018.

Electrochemical Society, Advances in Electropolishing Techniques, Pennington, NJ, 2019.

Metal Finishing Association, Surface Treatments for Corrosion Protection, Birmingham, UK, 2020.

Society of Manufacturing Engineers, Precision Engineering with Nickel Alloys, Dearborn, MI, 2021.

Learn about our latest products and discounts through SMS or email