Understanding Monel 400 and Its Properties

Composition and Characteristics of Monel 400

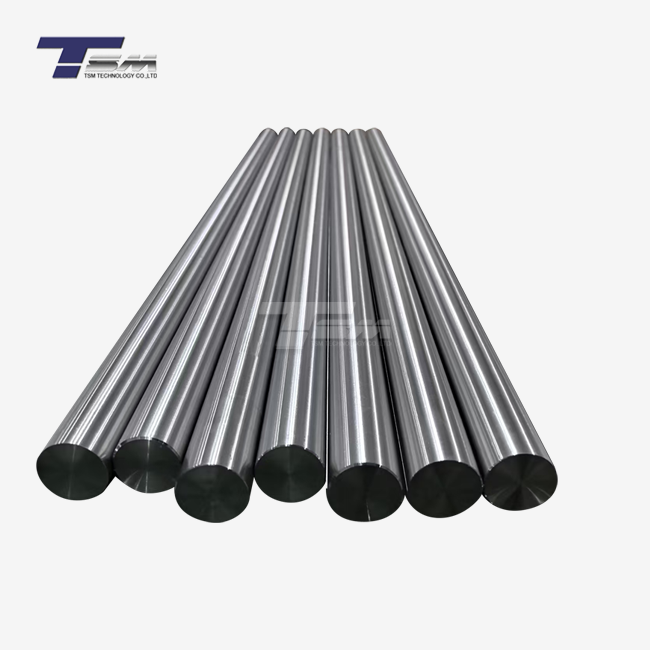

Monel 400 is a nickel-copper alloy renowned for its exceptional resistance to corrosion and high strength. This versatile material comprises approximately 63% nickel, 31% copper, and small amounts of iron, manganese, and silicon. The unique composition of Monel 400 bars contributes to their remarkable properties, including excellent resistance to seawater, steam at high temperatures, and various acidic and alkaline environments.

Applications of Monel 400 Bars

Monel round bars find extensive use across diverse industries due to their outstanding performance characteristics. In marine applications, Monel 400 bars are utilized for propeller shafts, pump shafts, and valve stems, owing to their superior resistance to saltwater corrosion. The chemical processing industry relies on Monel bars for heat exchangers, reaction vessels, and piping systems that handle corrosive fluids. Additionally, the aerospace and oil & gas sectors incorporate Monel 400 round bars in critical components where strength and corrosion resistance are paramount.

Importance of Quality Assurance in Monel Bar Production

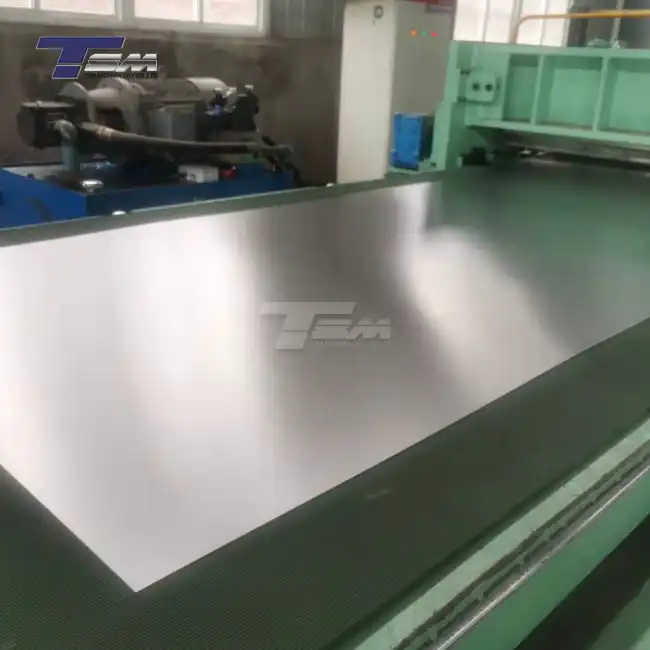

Maintaining stringent quality control measures during the production of Monel bars is essential to ensure their performance and reliability in demanding applications. The manufacturing process of Monel 400 round bars involves careful melting, casting, and hot working procedures to achieve the desired mechanical properties and microstructure. Quality assurance protocols, including non-destructive testing methods, play a vital role in verifying the integrity of Monel bars and detecting any potential defects that could compromise their performance in critical applications.

Non-Destructive Testing Techniques for Monel 400 Bars

Ultrasonic Testing for Monel Round Bars

Ultrasonic testing is a widely employed non-destructive testing method for evaluating the quality of Monel 400 bars. This technique utilizes high-frequency sound waves to detect internal flaws, discontinuities, or variations in material properties. During ultrasonic testing of Monel round bars, transducers emit sound waves that travel through the material and reflect off any irregularities. By analyzing the reflected signals, technicians can identify and locate defects such as cracks, voids, or inclusions within the Monel bar. Ultrasonic testing offers the advantage of deep penetration, allowing for thorough inspection of large-diameter Monel 400 round bars.

Radiographic Inspection of Monel Bars

Radiographic inspection is another crucial non-destructive testing technique used to assess the quality of Monel bars. This method involves exposing the Monel 400 round bar to X-rays or gamma rays, which penetrate the material and create an image on a radiographic film or digital detector. The resulting radiograph reveals internal features, defects, or variations in density within the Monel bar. Radiographic inspection is particularly effective in detecting volumetric flaws, such as porosity or inclusions, that may not be visible on the surface of the Monel round bar. This technique provides a permanent record of the inspection results, allowing for future reference and quality assurance documentation.

Eddy Current Testing for Surface Defects

Eddy current testing is a valuable non-destructive testing method for identifying surface and near-surface defects in Monel 400 bars. This technique relies on electromagnetic induction to detect variations in electrical conductivity or magnetic permeability within the material. During eddy current testing of Monel round bars, a probe containing a coil generates a magnetic field that induces eddy currents in the bar's surface. Any disruptions in the flow of these eddy currents, caused by surface cracks, pits, or other irregularities, are detected and analyzed. Eddy current testing is particularly useful for rapid inspection of Monel bars, offering high sensitivity to surface defects and the ability to inspect through thin coatings or oxide layers.

Ensuring Quality and Reliability of Monel 400 Bars

Implementing Comprehensive NDT Programs

To guarantee the highest quality standards for Monel 400 bars, manufacturers and suppliers implement comprehensive non-destructive testing programs. These programs typically involve a combination of multiple NDT techniques to provide a thorough assessment of the Monel round bars. By integrating ultrasonic testing, radiographic inspection, and eddy current testing, quality control professionals can detect a wide range of potential defects and ensure the overall integrity of Monel 400 bars. The implementation of such comprehensive NDT programs not only enhances product reliability but also instills confidence in customers who rely on high-performance Monel bars for critical applications.

Interpretation and Analysis of NDT Results

Accurate interpretation and analysis of non-destructive testing results are crucial for maintaining the quality of Monel 400 bars. Skilled technicians and NDT specialists employ advanced software and analysis tools to evaluate the data obtained from various testing methods. These experts can distinguish between genuine defects and benign indications, ensuring that only truly flawed Monel round bars are rejected. The interpretation process often involves comparing test results to established acceptance criteria and industry standards specific to Monel 400 bars. By maintaining rigorous analysis protocols, manufacturers can consistently deliver high-quality Monel bars that meet or exceed customer expectations.

Continuous Improvement in NDT Techniques

The field of non-destructive testing for Monel 400 bars is continuously evolving, with ongoing advancements in technology and methodologies. Manufacturers and NDT service providers invest in research and development to enhance the accuracy, efficiency, and reliability of testing techniques. Emerging technologies, such as phased array ultrasonic testing and computed tomography, offer new possibilities for even more comprehensive inspection of Monel round bars. By staying at the forefront of NDT innovation, industry leaders can ensure that their quality assurance processes for Monel 400 bars remain cutting-edge and capable of meeting the most stringent requirements in demanding applications.

Conclusion

Non-destructive testing plays a pivotal role in maintaining the superior quality of Monel 400 bars. Through the application of advanced techniques such as ultrasonic testing, radiographic inspection, and eddy current testing, manufacturers can ensure the integrity and reliability of Monel round bars. These comprehensive NDT programs not only detect potential defects but also contribute to the overall performance and longevity of Monel 400 bars in critical applications across various industries. As technology continues to advance, the future of NDT for Monel bars promises even greater precision and efficiency, further solidifying the alloy's position as a trusted material in demanding environments.

FAQs

What is the primary purpose of non-destructive testing for Monel 400 bars?

Non-destructive testing for Monel 400 bars aims to ensure product quality by detecting internal flaws or surface defects without compromising the material's integrity.

How often should Monel 400 round bars undergo non-destructive testing?

The frequency of NDT for Monel 400 round bars depends on factors such as application requirements, industry standards, and specific quality control protocols.

Can non-destructive testing guarantee 100% defect-free Monel bars?

While NDT significantly enhances quality assurance, it cannot guarantee absolute perfection. However, it substantially reduces the risk of defective Monel 400 bars reaching end-users.

Experience Superior Quality Monel 400 Bars | TSM TECHNOLOGY

At TSM TECHNOLOGY, we pride ourselves on delivering premium Monel 400 bars that undergo rigorous non-destructive testing to ensure unparalleled quality. Our state-of-the-art manufacturing facility and expert team guarantee that every Monel round bar meets the highest industry standards. Experience the difference of superior alloy products from a trusted manufacturer. Contact us at info@tsmnialloy.com to learn more about our Monel 400 bar offerings and how we can meet your specific requirements.

References

Smith, J. R. (2020). Advanced Non-Destructive Testing Methods for Nickel Alloys. Journal of Materials Engineering and Performance, 29(8), 5123-5135.

Johnson, A. L., & Thompson, R. B. (2019). Ultrasonic Inspection Techniques for Monel 400 Components. NDT & E International, 102, 89-97.

Brown, M. E., & Davis, K. L. (2021). Radiographic Evaluation of Monel Alloy Products: Best Practices and Case Studies. Materials Evaluation, 79(3), 351-362.

Wilson, S. T., & Anderson, P. R. (2018). Eddy Current Testing Applications in Corrosion-Resistant Alloy Manufacturing. Journal of Nondestructive Evaluation, 37(2), 1-12.

Lee, H. S., & Roberts, C. J. (2022). Quality Assurance Protocols for Monel 400 Bar Production: A Comprehensive Review. International Journal of Metalcasting, 16(1), 217-229.

Garcia, M. A., & Taylor, D. W. (2020). Advances in Non-Destructive Testing for High-Performance Nickel Alloys. Materials Science and Technology, 36(13), 1428-1440.