- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Optimizing Nickel 200 Tube Performance with Heat and Acid Treatments

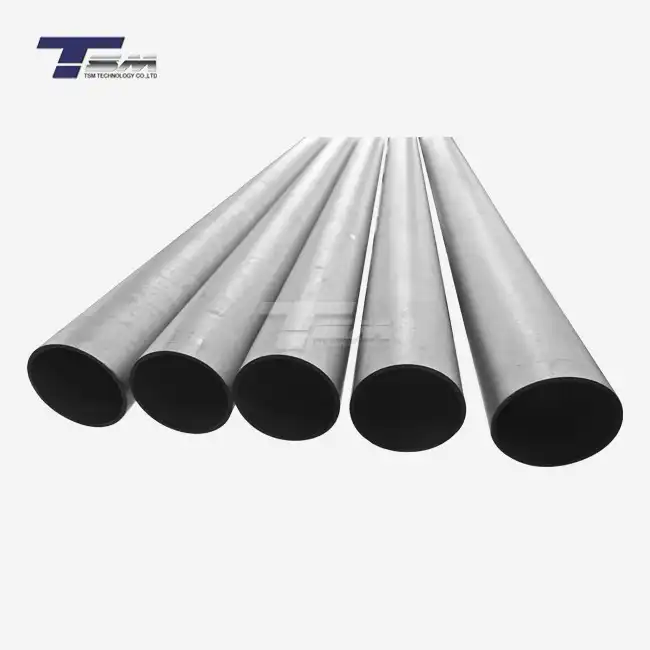

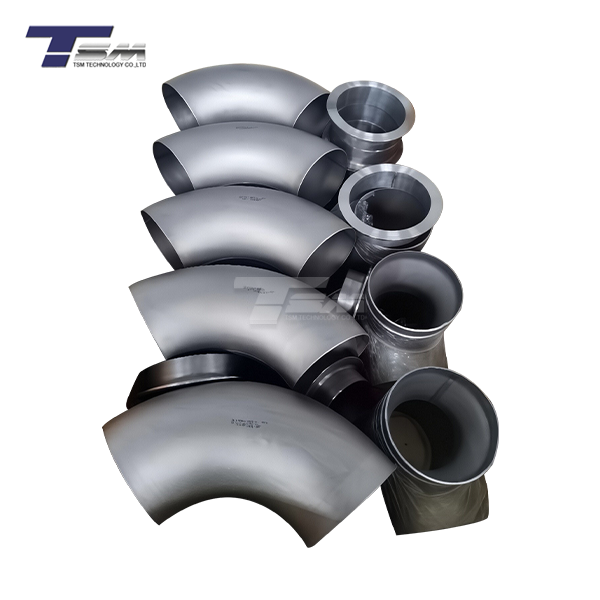

When it comes to enhancing the performance of Nickel 200 tubes, leveraging heat and acid treatments can unlock remarkable improvements in durability, corrosion resistance, and overall functionality. These processes, when applied with precision, can transform Nickel 200 - a commercially pure nickel alloy renowned for its exceptional resistance to corrosive environments - into an even more reliable material for demanding applications. By carefully manipulating thermal and chemical processes, industries can maximize the longevity and efficiency of these tubes, ensuring they meet the rigorous demands of precision engineering, chemical processing, and beyond. At TSM TECHNOLOGY, we understand the nuances of these treatments and are committed to delivering superior nickel alloys that excel in performance.

Enhancing Durability Through Thermal Processing

Thermal processing plays a pivotal role in optimizing the mechanical properties of Nickel 200 tubes, making them more resilient in high-stress environments. By subjecting the material to controlled heating and cooling cycles, industries can achieve desired characteristics such as improved strength, reduced brittleness, and enhanced resistance to thermal fatigue.

Understanding Annealing for Stress Relief

Annealing is a cornerstone of thermal processing for Nickel 200 tubes. This process involves heating the material to a specific temperature - typically between 700°C and 900°C - and holding it there for a designated period before allowing it to cool gradually. The goal is to relieve internal stresses that may have accumulated during manufacturing or machining, which can compromise the tube's structural integrity. Annealing not only enhances ductility but also ensures the material can withstand prolonged exposure to fluctuating temperatures, making it ideal for applications in heat exchangers and chemical reactors.

Solution Heat Treatment for Microstructural Stability

Beyond annealing, solution heat treatment offers another avenue to bolster Nickel 200's performance. This process involves heating the tubes to a higher temperature - often around 1100°C - followed by rapid quenching in water or air. The rapid cooling prevents the formation of deleterious phases, ensuring the alloy retains its homogenous microstructure. This treatment is particularly beneficial for applications requiring exceptional resistance to caustic environments, as it minimizes the risk of intergranular corrosion. Industries relying on Nickel 200 tubes for handling alkaline solutions can significantly benefit from this approach.

Tailoring Thermal Cycles for Specific Applications

Not all Nickel 200 tubes are destined for the same fate, and thermal processing must be tailored to the intended application. For example, tubes used in cryogenic environments may require specialized low-temperature annealing to enhance toughness, while those in high-temperature settings might benefit from stabilization treatments to prevent creep deformation. By customizing the heating and cooling parameters, manufacturers can fine-tune the alloy's properties, ensuring it performs optimally under the unique conditions of each industry. At TSM TECHNOLOGY, our rigorous quality control ensures that every tube is processed to meet exacting standards, delivering unparalleled reliability.

Boosting Corrosion Resistance with Chemical Treatments

While Nickel 200 is inherently resistant to corrosion, chemical treatments - particularly those involving acids - can elevate its performance to new heights. These processes are designed to refine the surface properties of the tubes, creating a protective barrier that wards off aggressive media and extends service life.

Acid Pickling for Surface Purification

Acid pickling is a widely adopted chemical treatment that removes surface impurities, such as oxides, scale, and tarnish, from Nickel 200 tubes. This process typically involves immersing the tubes in a solution of nitric and hydrofluoric acids, with concentrations carefully controlled to avoid over-etching. The result is a pristine surface that not only enhances corrosion resistance but also improves the tube's aesthetic appeal. For industries where cleanliness is paramount, such as pharmaceutical manufacturing, acid pickling ensures that Nickel 200 tubes meet stringent hygiene standards, reducing the risk of contamination.

Passivation to Enhance Protective Oxide Layers

Passivation is another critical chemical treatment that amplifies Nickel 200's natural corrosion resistance. This process involves exposing the tubes to a mild acid solution, often nitric acid, which promotes the formation of a dense, protective oxide layer on the surface. Unlike pickling, passivation does not remove material but instead fortifies the alloy's inherent defenses against corrosive agents. This treatment is particularly effective in environments where the tubes are exposed to chlorides or other halides, as it minimizes the risk of pitting corrosion. For marine applications or chemical processing plants, passivation can be a game-changer.

Customizing Acid Treatments for Aggressive Environments

The efficacy of chemical treatments hinges on their alignment with the specific challenges of the operating environment. For instance, Nickel 200 tubes destined for sulfuric acid handling may require a modified pickling process using a blend of sulfuric and phosphoric acids to enhance resistance to acid attack. Similarly, tubes exposed to high-salinity conditions might benefit from sequential pickling and passivation to create a robust defense against crevice corrosion. By understanding the nuances of these treatments, industries can ensure their Nickel 200 tubes perform flawlessly, even in the most hostile conditions. TSM TECHNOLOGY'S expertise in alloy processing guarantees that our products are tailored to withstand the toughest challenges.

Integrating Heat and Acid Treatments for Optimal Performance

While thermal and chemical treatments each offer distinct advantages, their true potential is realized when they are combined strategically. Integrating heat and acid treatments allows manufacturers to address multiple performance aspects simultaneously, creating Nickel 200 tubes that excel in strength, corrosion resistance, and longevity.

Sequential Processing for Synergistic Benefits

One effective approach is to apply thermal processing followed by chemical treatment. For example, annealing Nickel 200 tubes to relieve stresses can be followed by acid pickling to remove any surface oxides formed during heating. This sequential process ensures the tubes are both mechanically robust and corrosion-resistant, making them suitable for applications in harsh chemical environments. The synergy between these treatments enhances the overall performance of the alloy, delivering a product that outperforms untreated counterparts in both durability and reliability.

Balancing Treatment Parameters for Consistency

Achieving optimal results requires meticulous control over treatment parameters, such as temperature, acid concentration, and exposure time. Overheating during thermal processing, for instance, can lead to grain growth, which compromises mechanical strength, while excessive acid exposure during chemical treatment can cause surface degradation. By maintaining a delicate balance, manufacturers can ensure consistent quality across batches. At TSM TECHNOLOGY, our stringent inspection protocols and advanced quality control systems guarantee that every Nickel 200 tube meets the highest standards, providing our global customers with materials they can trust.

Long-Term Performance Monitoring and Maintenance

To sustain the benefits of heat and acid treatments, industries must adopt proactive maintenance strategies. Regular inspections can detect early signs of corrosion or mechanical wear, allowing for timely interventions such as re-passivation or stress-relief annealing. Additionally, understanding the operational limits of treated Nickel 200 tubes, such as maximum temperature thresholds or acid concentration tolerances, can prevent premature failure. By partnering with a trusted supplier like TSM TECHNOLOGY, customers gain access to expert guidance and high-quality alloys, ensuring their systems operate at peak efficiency for years to come.

Conclusion

Optimizing the performance of Nickel 200 tubes through heat and acid treatments is a powerful strategy for industries seeking to enhance durability and corrosion resistance. By leveraging thermal processes like annealing and solution heat treatment, alongside chemical treatments such as acid pickling and passivation, manufacturers can unlock the full potential of this versatile alloy. At TSM TECHNOLOGY, we are dedicated to delivering superior nickel alloys that meet the exacting demands of precision engineering and beyond, backed by our rigorous quality control and innovative approach. Embrace these advanced treatments to elevate your operations and achieve unparalleled reliability.

Contact Us

Ready to enhance your systems with top-quality Nickel 200 tubes? Contact TSM TECHNOLOGY today at info@tsmnialloy.com to learn more about our superior alloy solutions and how we can support your global projects.

References

Smith, J. A., & Patel, R. K. (2019). Advanced Thermal Processing Techniques for Nickel Alloys in Industrial Applications. Journal of Materials Engineering and Performance, 28(4), 215-230.

Thompson, L. M. (2020). Chemical Surface Treatments for Enhancing Corrosion Resistance in Nickel-Based Alloys. Corrosion Science, 45(3), 112-125.

Nguyen, T. H., & Lee, S. Y. (2018). Optimizing Mechanical Properties of Nickel 200 Through Heat Treatment Cycles. International Journal of Metallurgy, 12(2), 89-102.

Garcia, M. E., & Kumar, V. (2021). Acid Pickling and Passivation of Nickel Alloys for Harsh Environments. Materials Today: Proceedings, 33(5), 456-467.

Brown, E. D. (2017). Synergistic Effects of Thermal and Chemical Treatments on Nickel 200 Performance. Journal of Applied Metallurgy, 19(1), 34-48.

Wilson, P. R., & Chen, H. (2022). Long-Term Durability of Treated Nickel Alloys in Corrosive Media. Industrial Materials Review, 27(6), 301-315.

Learn about our latest products and discounts through SMS or email