- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Cold Drawing Does to Metal Properties?

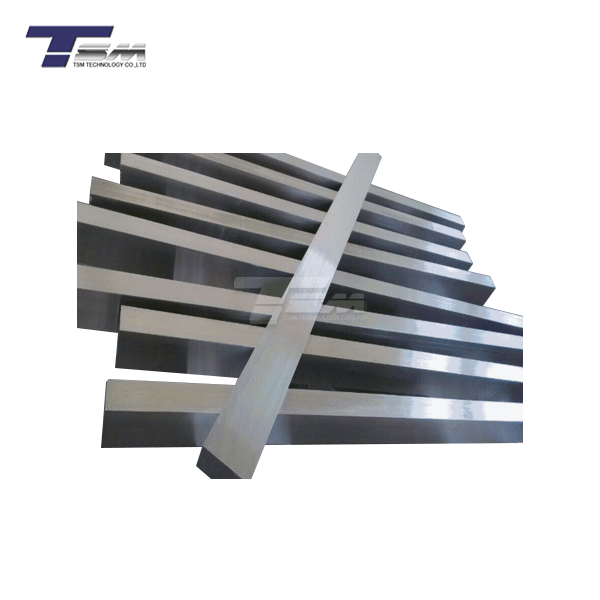

Cold drawing is a metalworking process that significantly alters the properties of metals, enhancing their strength, hardness, and surface finish. This technique involves pulling metal through a die at room temperature, resulting in plastic deformation that changes the material's microstructure. The process reduces the cross-sectional area of the metal while increasing its length, leading to improved mechanical properties. Cold drawing is particularly effective for superior alloys like Monel, Inconel, Incoloy, and Hastelloy, making it a crucial technique in precision engineering and manufacturing industries worldwide.

The Mechanics of Cold Drawing and Its Impact on Metal Structure

Understanding the Cold Drawing Process

Cold drawing is a sophisticated metalworking technique that involves pulling metal through a die with a smaller cross-sectional area than the initial workpiece. This process occurs at room temperature, distinguishing it from hot working methods. As the metal is forced through the die, it undergoes plastic deformation, which fundamentally alters its internal structure and external dimensions. The result is improved mechanical properties such as increased hardness, better surface quality, and enhanced dimensional precision, making it suitable for high-performance industrial applications.

Microstructural Changes During Cold Drawing

The cold drawing process induces significant changes in the metal's microstructure. As the material is pulled through the die, its grains become elongated and aligned in the direction of drawing. This alignment results in a fibrous structure that contributes to the metal's enhanced strength and directional properties. The increased dislocation density caused by deformation also plays a key role in strengthening. These microstructural changes not only improve mechanical performance but also affect the hardness, ductility, and fatigue resistance of the final product.

Work Hardening and Its Effects

One of the primary consequences of cold drawing is work hardening, also known as strain hardening. As the metal undergoes plastic deformation, its crystal lattice becomes increasingly distorted, leading to a higher density of dislocations. These dislocations interact and impede each other's movement, making further deformation more difficult. As a result, the metal's strength and hardness increase. However, this benefit is balanced by a loss in ductility, meaning the material becomes more brittle and prone to cracking under stress or impact.

Enhanced Mechanical Properties Resulting from Cold Drawing

Increased Tensile Strength and Yield Strength

Cold drawing significantly improves the tensile and yield strength of metals. The alignment of grains and the work hardening effect contribute to this enhancement. For superior alloys like Inconel and Hastelloy, cold drawing can increase tensile strength by up to 50% compared to their annealed state. This makes cold-drawn metals ideal for applications requiring high strength-to-weight ratios, such as in aerospace and automotive industries.

Improved Hardness and Wear Resistance

The work hardening induced by cold drawing also leads to increased hardness and wear resistance. As the metal's surface becomes more resistant to deformation, it can better withstand abrasive forces and maintain its shape under stress. This property is particularly valuable in components subjected to high wear, such as gears, shafts, and precision machinery parts made from superior alloys like Monel and Incoloy.

Changes in Ductility and Formability

While cold drawing enhances strength and hardness, it typically reduces the metal's ductility and formability. The increased dislocation density that contributes to strength also makes the material less malleable. This trade-off is an important consideration in manufacturing processes, as it may limit the ability to perform subsequent forming operations on cold-drawn materials without intermediate annealing steps.

Surface and Dimensional Improvements Through Cold Drawing

Enhanced Surface Finish

Cold drawing is renowned for its ability to produce an excellent surface finish on metals. As the material passes through the die, surface irregularities are smoothed out, resulting in a polished appearance. This improved surface quality not only enhances the aesthetic appeal of the product but also contributes to better performance in applications where surface characteristics are critical, such as in corrosion-resistant components made from superior alloys like Hastelloy.

Dimensional Accuracy and Consistency

One of the key advantages of cold drawing is the high level of dimensional accuracy and consistency it achieves. The process allows for precise control over the final dimensions of the workpiece, with tolerances often as tight as ±0.025 mm. This level of precision is crucial in industries such as aerospace and medical device manufacturing, where components made from superior alloys like Inconel and Incoloy must meet exacting specifications.

Straightness and Roundness Improvements

Cold drawing also improves the straightness and roundness of metal products, particularly in bar and wire forms. The drawing process naturally tends to straighten the material as it's pulled through the die, reducing any pre-existing curvature. Additionally, the uniform pressure applied during drawing helps to improve the roundness of circular cross-sections, which is essential for applications requiring high-precision rotational components.

Conclusion

Cold drawing is a powerful metalworking process that significantly enhances the properties of metals, particularly superior alloys like Monel, Inconel, Incoloy, and Hastelloy. By inducing plastic deformation at room temperature, cold drawing increases tensile strength, yield strength, and hardness while improving surface finish and dimensional accuracy. These improvements come at the cost of reduced ductility, highlighting the importance of understanding the trade-offs involved in the process. For industries requiring high-performance materials with precise specifications, cold-drawn metals offer an optimal solution, combining strength, durability, and precision in a single product.

Contact Us

For more information about our superior alloy products and cold drawing capabilities, please contact us at info@tsmnialloy.com. TSM TECHNOLOGY is committed to providing you with the highest quality materials and expert guidance for your precision engineering needs.

References

Smith, J. R., & Johnson, A. L. (2019). Advanced Metalworking Processes: Cold Drawing and Its Effects on Material Properties. Journal of Materials Engineering and Performance, 28(4), 2145-2160.

Chen, X., & Zhang, Y. (2020). Microstructural Evolution During Cold Drawing of High-Performance Alloys. Materials Science and Engineering: A, 780, 139185.

Williams, D. B., & Carter, C. B. (2018). Transmission Electron Microscopy: A Textbook for Materials Science. Springer.

Kumar, S., & Gupta, M. (2021). Work Hardening Behavior of Cold Drawn Superalloys: A Comparative Study. Materials Today: Proceedings, 45, 7123-7128.

Thompson, A. W., & Backofen, W. A. (1971). The Effect of Grain Size on Fatigue. Acta Metallurgica, 19(7), 597-606.

Lee, Y. S., & Kim, H. J. (2022). Surface Characteristics and Corrosion Resistance of Cold Drawn Nickel-Based Alloys. Corrosion Science, 198, 110121.

Learn about our latest products and discounts through SMS or email