Understanding Monel 400 and Its Composition

The Unique Blend of Nickel and Copper

Monel 400 is a remarkable nickel-copper alloy, renowned for its exceptional properties. The composition typically consists of approximately 63% nickel and 31% copper, with small amounts of iron, manganese, and other elements. This carefully balanced mixture results in a material that combines the best attributes of its primary components, creating a synergistic effect that enhances its overall performance.

The high nickel content in Monel 400 round bar contributes significantly to its corrosion resistance, particularly in reducing environments. Nickel's ability to form a stable passive layer on the surface of the alloy protects against various corrosive media. On the other hand, copper enhances the alloy's resistance to oxidizing acids and improves its workability.

Physical and Mechanical Properties

Monel 400 bar boasts an impressive set of physical and mechanical properties that make it suitable for a wide range of applications. Its density is approximately 8.8 g/cm³, which is slightly lower than that of pure nickel. The alloy exhibits excellent strength and ductility, with a typical tensile strength ranging from 550 to 750 MPa and an elongation of 35-60%.

The thermal conductivity of Monel 400 is around 21.8 W/(m·K) at room temperature, which is higher than many stainless steels but lower than pure copper. This property makes it suitable for applications requiring moderate heat transfer capabilities. Additionally, Monel round bar has a relatively low electrical resistivity of about 0.547 µΩ·m, making it a good conductor of electricity.

Crystalline Structure and Its Impact on Properties

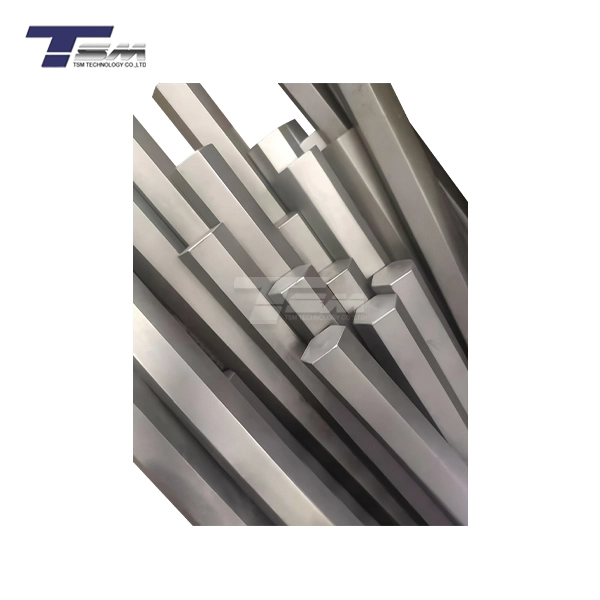

Monel 400 possesses a face-centered cubic (FCC) crystal structure, which is characteristic of many nickel-based alloys. This structure contributes to the alloy's excellent ductility and formability, allowing it to be easily shaped and worked into various forms, including bars, rods, and sheets.

The FCC structure also plays a crucial role in the alloy's resistance to oxidation and corrosion. The close-packed arrangement of atoms in the FCC lattice creates a dense structure that inhibits the diffusion of corrosive species into the material. This, combined with the protective oxide layer that forms on the surface, enhances the overall durability of Monel 400 bar in harsh environments.

Oxidation Mechanisms in Harsh Conditions

High-Temperature Oxidation Processes

When exposed to high temperatures, Monel 400 undergoes a complex oxidation process that significantly influences its performance. As the temperature rises, the rate of oxidation increases, following an Arrhenius-type relationship. The initial stage of oxidation involves the rapid formation of a thin, adherent oxide layer on the surface of the Monel 400 round bar.

This oxide layer, primarily composed of NiO and CuO, acts as a protective barrier against further oxidation. The growth of this layer is governed by the diffusion of metal ions outward and oxygen ions inward through the oxide scale. As the oxide layer thickens, the diffusion rate decreases, leading to a parabolic growth rate of the oxide scale over time.

Effects of Corrosive Elements on Oxidation

In harsh environments, the presence of corrosive elements can significantly impact the oxidation behavior of Monel bar. Sulfur-containing species, for instance, can accelerate the oxidation rate by forming low-melting-point nickel sulfides. These sulfides can disrupt the protective oxide layer, leading to accelerated corrosion.

Chloride ions, commonly found in marine environments, can also penetrate the oxide layer and cause localized breakdown of passivity. This can result in pitting corrosion, which is particularly dangerous as it can lead to rapid, localized material loss. However, the high copper content in Monel 400 provides some resistance against chloride attack, making it more resilient than many other alloys in marine applications.

Role of Alloying Elements in Oxidation Resistance

The alloying elements in Monel 400 play crucial roles in enhancing its oxidation resistance. While nickel and copper form the bulk of the alloy, minor additions of other elements contribute significantly to its performance in harsh conditions. Iron, typically present at about 2.5%, helps improve the alloy's strength and resistance to sulfur attack.

Manganese, usually added in small amounts (around 1.5%), acts as a deoxidizer during the melting process and contributes to improved hot workability. Some grades of Monel 400 may also contain small amounts of silicon, which can enhance the adherence of the oxide layer, further improving the alloy's oxidation resistance at elevated temperatures.

Performance of Monel 400 in Different Harsh Environments

Marine and Offshore Applications

Monel 400 bar excels in marine and offshore environments, where its resistance to seawater corrosion is paramount. The alloy's ability to withstand the corrosive effects of chloride ions makes it an ideal choice for components exposed to saltwater, such as pump shafts, valve stems, and fasteners used in marine structures.

In offshore oil and gas platforms, where materials are subjected to a combination of seawater spray, high temperatures, and corrosive gases, Monel 400 round bar demonstrates exceptional durability. Its resistance to stress corrosion cracking in chloride-rich environments further enhances its suitability for these demanding applications.

Chemical Processing Industry

In the chemical processing industry, Monel bar finds extensive use due to its excellent resistance to a wide range of corrosive media. It performs exceptionally well in handling fluorine, hydrofluoric acid, and sulfuric acid, making it a preferred material for piping systems, heat exchangers, and reaction vessels in chemical plants.

The alloy's ability to maintain its integrity in both reducing and mildly oxidizing environments sets it apart from many other materials. This versatility allows Monel 400 to be used in processes involving organic and inorganic chemicals, where its resistance to stress corrosion cracking and pitting corrosion is particularly valuable.

High-Temperature Industrial Settings

In high-temperature industrial settings, such as furnaces and heat treatment equipment, Monel 400 round bar demonstrates remarkable oxidation resistance. The alloy can maintain its structural integrity and corrosion resistance at temperatures up to 540°C (1000°F), making it suitable for components in heat-treating furnaces, flue gas desulfurization systems, and other high-temperature applications.

The formation of a stable, adherent oxide layer on the surface of Monel 400 at elevated temperatures protects against further oxidation, ensuring long-term reliability in these harsh conditions. This property, combined with its good thermal conductivity, makes Monel bar an excellent choice for heat exchanger tubes and other components in high-temperature processing equipment.

Conclusion

The exceptional oxidation resistance of Monel 400 bar in harsh conditions stems from its unique composition and microstructure. Its ability to form a protective oxide layer, coupled with the synergistic effects of nickel and copper, enables it to withstand corrosive environments, high temperatures, and aggressive chemicals. From marine applications to chemical processing and high-temperature industrial settings, Monel 400 round bar consistently delivers superior performance. As industries continue to face increasingly challenging operational conditions, the reliability and durability of Monel bar make it an invaluable material for ensuring long-term integrity and efficiency in critical applications.

Contact Us

For more information on how Monel 400 can benefit your specific application or to explore our range of superior nickel alloys, please don't hesitate to contact us at info@tsmnialloy.com. TSM TECHNOLOGY is committed to providing high-quality alloy solutions tailored to your needs.