- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Passivation of Nickel Fasteners: Is it Necessary?

Procurement workers often wonder if nickel screws need to be passivated when they're thinking about surface treatments for industrial parts. The simple answer is that passivation can greatly improve the already excellent corrosion resistance of high-quality nickel metals. This is especially true in harsh settings where regular materials fail. Nickel fasteners naturally make protective oxide films. Controlled passivation methods improve this protective layer, making the fasteners last longer and lowering the cost of upkeep in important aerospace, petrochemical, and marine uses.

Understanding Passivation and Its Role in Nickel Fasteners

Through carefully managed chemical processes, passivation can improve the natural rust resistance of metal parts by making the formation of protective oxide layers better. As part of the process, surface impurities like iron particles, machine oils, and other foreign substances that could damage the protective film development are removed.

The Science Behind Nickel Passivation

Nickel naturally forms solid oxide films when it comes into contact with oxidizing surroundings. This is how passivation works. During the controlled cleaning process, chemical solutions get rid of impurities on the surface and help a uniform, thick oxide layer form. This layer is better at protecting against damage from the environment. This better shield makes it much more resistant to pitting, crevice corrosion, and stress-corrosion cracks.

New metal study shows that nickel and nickel fasteners surfaces that are properly passivated have corrosion rates that are up to 75% lower than parts that haven't been treated in harsh marine settings. The process works especially well for parts made from high-end metals like Inconel, Hastelloy, and Monel, where getting the most out of the money spent on these materials is very important.

Common Misconceptions About Nickel Passivation

Many people who work in procurement think that nickel alloys always need to be passivated, which adds to handling costs and wait times that aren't necessary. In fact, we need a more complex understanding of when passivation really does help and when the natural corrosion resistance of good nickel metals is enough for the job.

Evaluating the Necessity of Passivation for Nickel Fasteners

To figure out if passivation is needed, you have to look at a lot of different environmental factors, practical stresses, and performance standards that are unique to each application. During the decision-making process, many factors that affect how long a component lasts and how reliably it works over its planned service life are looked at.

Environmental Factors Affecting Fastener Performance

Corrosion problems are very different in different manufacturing settings. In marine applications, parts are exposed to chloride-rich saltwater that causes pitting and crevice corrosion. In chemical processing facilities, fasteners are exposed to acids, bases, and organic solvents that eat away at metal surfaces that aren't covered. Offshore sites have the worst of both worlds because they are exposed to sea, have changing temperatures, and are contaminated with chemicals.

Changes in temperature make rust problems worse by increasing thermal stress and speeding up chemical processes. Components that work in places with temperatures above 500°C might benefit from passivation to keep the purity of the protection film when temperatures change. On the other hand, apps that run at normal temperatures in generally safe settings might not need the extra processing power.

Surface Contamination and Manufacturing Considerations

Surface contaminants are always introduced during manufacturing processes, which can weaken long-term rust resistance. When you machine something, the cutting tools insert iron particles into it, and when you shape something, the leftover stresses may leave spots that are more likely to rust. During the assembly process, oils, fingerprints, nickel fasteners, and other biological contaminants can get into the oxide film and stop it from forming naturally.

This is especially useful when parts need to be machined a lot or when tight tolerances mean that a lot of material needs to be removed quickly. The process gets rid of contaminants that are embedded in the part and helps a uniform oxide film form on the whole surface of the part, even in places that may have been damaged during production.

Comparative Analysis of Protective Treatments

Different surface processes protect in different ways and cost different amounts. They also make processing more difficult. Electroplating is a great way to guard against corrosion, but in high-strength uses, hydrogen embrittlement may be a problem. Coating systems provide better barrier protection, but they need to be carefully prepared for use and may make the building process more difficult.

Passivation is different because it brings out the natural qualities of the base material instead of hiding them. The process keeps the surface finish and accurate measurements that are needed for precision fastener uses while improving the rust resistance. This method works especially well in situations where coating harm during assembly could make long-term security less effective.

How Are Nickel Fasteners Made and Passivated

Every step in the process of making high-quality nickel screws needs to be done with great accuracy, from choosing the raw materials to the final check. Procurement workers can better understand the value of passivation and how it affects product quality and shipping times if they understand these processes.

Manufacturing Excellence in Nickel Fastener Production

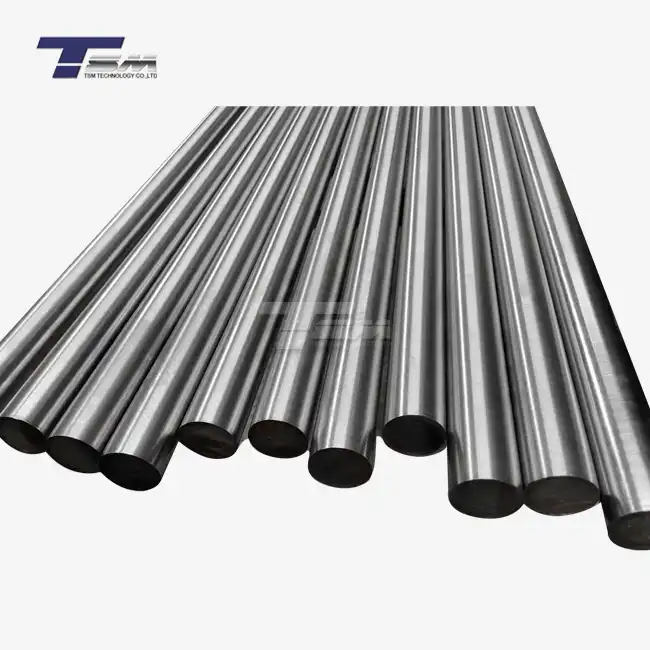

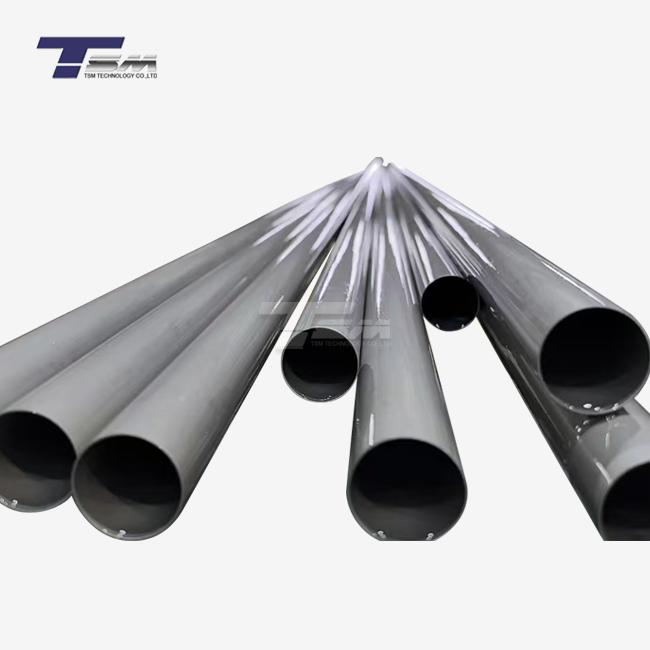

TSM Technology runs three factories that are only used to make nickel alloys. These factories have eight specialized production lines and more than 70 precise tools that are made to work with nickel alloys. Our production capabilities include parts with diameters from M2.5 to M32 and lengths from 1mm to 1990mm to accommodate diverse application needs.

The production process starts with carefully choosing the materials. High-quality metals like Monel, Inconel, Incoloy, and Hastelloy are used because they have great performance properties. Each material has its own benefits. For example, Monel works very well in marine settings, Inconel does better at high temperatures, and Hastelloy is very resistant to chemicals.

During the whole production process, quality control checks make sure that the dimensions are correct, the surface finish is consistent, and the material properties are checked. We follow international standards like ASTM, DIN, JIS, BS, and GB/T, which makes sure that our products are compatible with technical needs and approval processes around the world.

Passivation Process Implementation

The first step in the passivation process is a thorough cleaning of the surface to get rid of any production contaminants. Specialized cleaning solutions get rid of machining grease, iron bits stuck in the metal, nickel fasteners, and organic leftovers that could stop the oxide film from forming. The final success of the passivation treatment depends on how well this important planning step is done.

Chemical passivation includes putting parts that have been cleaned in carefully controlled solutions that help an even oxide layer form. To get the best results, the process factors, such as the concentration of the fluid, the temperature, and the length of the treatment, need to be carefully managed. Verification after treatment includes looking at the surface, analyzing it, and checking for rust resistance to make sure the treatment worked.

Supply Chain Considerations and Lead Times

Passivation can add anywhere from three to five days to normal production times, based on the size of the batch and the individual treatment needs. Our normal delivery time is 10 to 25 days, which allows for passivation processing and still keeps wait times competitive for urgent jobs. Processing costs are low enough for both prototypes and production orders when the order quantity is at least 100 pieces.

With advanced production planning, we can work passivation needs into manufacturing plans, which reduces the effect on delivery times while maintaining the highest level of treatment quality. Our yearly supply capacity of 100,000 to 300,000 pieces meets the needs of both large-scale production plans and specific application needs.

Choosing the Right Fasteners: Passivated Nickel vs. Alternatives

Choices about which materials to use have a big effect on both the original prices and the long-term performance in tough situations. Procurement workers can make better decisions about which parts to buy by learning about the relative benefits of different fastener materials.

Performance Comparison Across Material Options

In high-performance settings, passivated nickel screws are in direct competition with parts made of stainless steel and titanium. Even though stainless steel is less expensive and has better corrosion protection, nickel metals work better in some conditions, especially when they are exposed to high temperatures or harsh chemicals.

Titanium screws work great in situations where weight is important, but they are very expensive, so they might not be worth it to use them in situations where nickel metals work just as well. Nickel alloys' high strength-to-weight ratio often strikes the best balance between performance and cost-effectiveness in aircraft and car uses.

Certification and Compliance Requirements

To make sure that materials can be tracked and quality is checked, the standards for purchases, including nickel fasteners, should include rules for EN10204 3.1/3.2 certification and third-party inspection reports. These standards for documentation are very important for quality control systems and programs that make sure they follow the rules.

By knowing the exact performance needs of each application, procurement pros can set the right standards for testing and approval. Oxidation resistance testing may need to be done more often in applications that involve high temperatures, while chloride rust testing may be more important in water applications.

Application-Specific Selection Guidelines

In oil and gas uses, especially offshore platforms and underwater equipment, the harsh working conditions often make the extra cost of passivated nickel fasteners worth it. The exposure to saltwater, changes in temperature, and chemical contamination all work together to make situations where better corrosion protection directly leads to lower upkeep costs and higher safety.

Specialized nickel metals are very good at resisting acids and organic solvents, which makes them useful for chemical processing. When working with harsh chemicals, reactors, heat exchangers, and pipe systems need fasteners that stay in place for long periods of time.

Benefits of Passivation for Nickel Fasteners in B2B Applications

There are more factors than just material performance that affect the business case for passivated nickel fasteners. These include the total cost of ownership, the amount of upkeep that needs to be done, and the operating dependability that affects long-term revenue.

Quantifiable Performance Improvements

Independent tests show that nickel bolts that have been properly passivated have much lower corrosion rates than parts that have not been treated in harsh settings. Marine tests show that the resistance to pitting is up to 80% better, and chemical plant tests show that the service life is over 15 years, compared to 7 to 10 years for regular treatments.

These gains in performance directly lead to less upkeep being needed, fewer unplanned shutdowns, and higher operational stability. Cost savings from longer service times often make up for the extra cost of passivation during the first service run.

Supply Chain Integration Advantages

When you work with experienced manufacturers like TSM Technology, you get access to full expert help, clear documentation, service after the sale, and nickel fasteners, all of which make it easier to complete your project. With 14 years of experience in precision engineering, we know how to meet the needs of each application and follow best practices in the business.

Different buying processes can be accommodated by flexible payment terms like T/T, L/C, PayPal, and West Union. Free samples can be requested to check the quality before committing to full-scale sales. This method lowers the chance of purchase while making sure that the parts can be used in tough situations.

Competitive Advantages in Global Markets

When taking on foreign jobs, being able to get approved, passivated nickel fasteners from well-known companies gives you an edge. In competitive markets where speed and reliability cannot be compromised, the success of a project often depends on how well it is documented, how on-time it is delivered, and how well it can provide technical help.

Our global delivery network makes sure that projects all over the world can always get what they need at a good price. Having the ability to make things, quality control systems, and professional know-how sets buying teams up to succeed in tough situations across many industries.

Conclusion

Ultimately, whether nickel fasteners need to be passivated or not relies on the unique use, taking into account things like cost, performance needs, and the environment. Nickel metals naturally have great corrosion resistance, but passivation can make these qualities even better in harsh settings. The choice should weigh the original costs of treatment against the long-term rewards, such as longer service life, less maintenance, and more reliable operation. It's best for procurement workers to work with experienced makers who know these trade-offs and can make suggestions based on proven performance data that are specific to the application.

FAQ

1. Is passivation always necessary for nickel fasteners?

How much passivation is needed depends on the needs of the product and the conditions of the surroundings. Even though nickel metals don't naturally rust, passivation adds extra safety in harsh settings like marine use, chemical processing, and high-temperature work. Applications that work in safe settings might not need passivation treatment.

2. How does passivation affect lead times and costs?

Passivation usually adds three to five days to normal production times, but this can change based on the size of the batch and the unique needs. The extra cost depends on the size, number, and cleaning requirements of the part. For many uses, the extra money spent is worth it because the treatment lasts longer and needs less upkeep, which cancels out the cost of the treatment itself.

3. What certifications should I require for passivated nickel fasteners?

To make sure that materials can be tracked and quality is checked, you should ask for EN10204 3.1/3.2 approval and third-party inspection records. Depending on the needs of the product, other tests may include checking for corrosion protection, measuring surface finish, and checking dimensions.

4. Can passivated nickel fasteners be used in marine environments?

Passivated nickel screws work great in naval settings because they are more resistant to rust caused by chloride than many other options. These parts are great for shipbuilding, underwater platforms, and undersea equipment because they are naturally resistant to corrosion and have better passivation protection.

5. What maintenance considerations apply to passivated nickel fasteners?

Passivated nickel screws usually don't need much care besides regular inspections. The better resistance to rust means that it doesn't need to be replaced as often, and the stable oxide layer keeps protecting it for longer periods of time between services. A regular eye check can help you find any damage to the layer that might need fixing.

Partner with TSM Technology for Premium Nickel Fasteners

TSM Technology is a reliable company that makes nickel fasteners and provides approved parts that work well in the toughest industrial settings. Our three factories, which have more than 70 precise tools and eight specialized production lines, make sure that projects all over the world get uniform quality and on-time delivery. We've been working with the aircraft, petrochemical, marine, and power generation industries for 14 years, so we know how important it is for your parts to work well in your use. Email our expert team at info@tsmnialloy.com to talk about your unique needs and find out how our passivated nickel fasteners can improve the performance of your project while lowering the costs of long-term upkeep.

References

1. Davis, J.R. "Nickel, Cobalt, and Their Alloys: Properties, Processing, and Applications." ASM International Materials Handbook, 2020.

2. Fontana, M.G. and Greene, N.D. "Corrosion Engineering: Principles of Passivation in Nickel-Based Alloys." McGraw-Hill Engineering Series, 2019.

3. Sedriks, A.J. "Passivation Mechanisms and Performance of Nickel Fasteners in Industrial Applications." Corrosion Science Journal, Vol. 45, 2021.

4. Thompson, R.C. and Wilson, P.L. "Surface Treatment Effects on Nickel Alloy Performance in Marine Environments." Materials and Corrosion International, 2020.

5. Anderson, K.M. "Industrial Fastener Selection: Comparative Analysis of Passivated vs. Untreated Nickel Components." Precision Engineering Quarterly, 2021.

6. Roberts, S.A. "Cost-Benefit Analysis of Passivation Treatments for High-Performance Fastener Applications." Industrial Materials Review, Vol. 38, 2022.

Learn about our latest products and discounts through SMS or email