- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Post-Bend Heat Treatment and Finishing for Monel 400 Tubes

Post-bend heat treatment and finishing are crucial steps in optimizing the performance of Monel 400 tubes. These processes enhance the material's mechanical properties, relieve internal stresses caused by bending, and improve corrosion resistance. Proper heat treatment restores the alloy's microstructure, while finishing techniques like pickling and passivation create a protective oxide layer. Together, these processes ensure that Monel 400 tubing maintains its exceptional strength, ductility, and corrosion resistance in demanding applications across the marine, chemical, and aerospace industries.

The Importance of Post-Bend Heat Treatment for Monel 400 Tubes

Stress Relief and Microstructure Restoration

Post-bend heat treatment is essential for Monel 400 tubes as it relieves internal stresses induced during the bending process. When Monel tubing undergoes cold working or bending operations, residual stresses can accumulate within the material's structure. These stresses, if left unaddressed, may lead to reduced corrosion resistance, dimensional instability, or even premature failure under certain operating conditions.

Heat treatment at carefully controlled temperatures allows the nickel-copper alloy to recrystallize, forming a more uniform and stress-free microstructure. This process helps restore the material's original properties, ensuring that the Monel 400 pipe maintains its exceptional combination of strength, ductility, and corrosion resistance after fabrication.

Optimizing Mechanical Properties

Proper heat treatment can significantly enhance the mechanical properties of Monel 400 tubing. By carefully controlling the temperature and duration of the heat treatment process, manufacturers can achieve the optimal balance of strength and ductility required for specific applications. This is particularly important for bent Monel tubes that may experience complex stress states during service.

The heat treatment process can also help homogenize the alloy's composition, eliminating any localized variations that may have occurred during the bending operation. This results in more consistent properties throughout the entire length of the Monel 400 pipe, ensuring reliable performance in critical applications such as heat exchangers, chemical processing equipment, and marine environments.

Enhancing Corrosion Resistance

One of the primary advantages of Monel 400 is its exceptional corrosion resistance in various aggressive environments. However, the bending process can potentially compromise this resistance by creating surface defects or altering the material's passive layer. Post-bend heat treatment helps restore and even enhance the corrosion resistance of Monel tubing.

The heat treatment process promotes the formation of a stable, protective oxide layer on the surface of the Monel 400 tube. This layer acts as a barrier against corrosive agents, further improving the alloy's already impressive resistance to seawater, acids, and alkaline solutions. By ensuring optimal corrosion resistance, post-bend heat treatment contributes to the longevity and reliability of Monel 400 piping systems in demanding industrial applications.

Finishing Techniques for Monel 400 Tubes

Surface Preparation and Cleaning

Before applying any finishing treatments, it's crucial to properly prepare the surface of Monel 400 tubes. This preparation begins with thorough cleaning to remove any contaminants, oils, or debris that may have accumulated during the bending and heat treatment processes. Effective cleaning methods for Monel tubing include:

- Solvent degreasing to remove oils and organic contaminants

- Alkaline cleaning to eliminate inorganic substances

- Ultrasonic cleaning for hard-to-reach areas in complex bent configurations

After cleaning, the surface of the Monel 400 pipe may require mechanical preparation such as light abrasive blasting or brushing to remove any oxide scale formed during heat treatment. This step ensures a uniform surface for subsequent finishing processes and promotes optimal adhesion of protective coatings if required.

Pickling and Passivation

Pickling and passivation are critical finishing steps for Monel 400 tubes, particularly after heat treatment. These processes remove surface impurities and promote the formation of a stable, corrosion-resistant oxide layer. The pickling process typically involves immersing the Monel tubing in a carefully formulated acid solution, which selectively dissolves surface contaminants and oxides without significantly affecting the base metal.

Following pickling, passivation is performed to enhance the natural corrosion resistance of Monel 400. This process usually involves treating the surface with an oxidizing agent, such as nitric acid, which accelerates the formation of a protective passive layer. The resulting oxide film on the Monel 400 pipe surface provides excellent resistance to various corrosive media, including seawater and many chemicals.

Surface Finishing Options

Depending on the specific application requirements, Monel 400 tubes may undergo additional surface finishing treatments to enhance their performance or appearance. Some common surface finishing options include:

- Electropolishing: This electrochemical process smoothens and brightens the surface of Monel tubing, improving its corrosion resistance and reducing the potential for product adhesion in certain applications.

- Mechanical polishing: For applications requiring a specific surface roughness or aesthetic finish, mechanical polishing techniques can be employed to achieve the desired surface characteristics of Monel 400 pipes.

- Coating applications: In some cases, specialized coatings may be applied to Monel 400 tubes to provide additional protection against specific corrosive environments or to meet unique industry requirements.

The choice of surface finishing technique depends on factors such as the intended operating environment, regulatory requirements, and the specific performance characteristics desired for the Monel 400 tubing system.

Quality Control and Testing for Heat-Treated and Finished Monel 400 Tubes

Non-Destructive Testing Methods

Ensuring the quality and integrity of heat-treated and finished Monel 400 tubes is paramount for their reliable performance in critical applications. Non-destructive testing (NDT) methods play a crucial role in verifying the condition of Monel tubing without compromising its structural integrity. Common NDT techniques employed for Monel 400 pipes include:

- Ultrasonic testing to detect internal defects or thickness variations

- Eddy current inspection for surface and near-surface flaw detection

- Radiographic examination for identifying internal discontinuities

- Dye penetrant testing for surface defect detection on bent sections

These NDT methods allow manufacturers to assess the quality of heat-treated and finished Monel 400 tubes comprehensively, ensuring that they meet the stringent requirements of industries such as aerospace, chemical processing, and marine engineering.

Mechanical Property Verification

Post-bend heat treatment and finishing processes can significantly influence the mechanical properties of Monel 400 tubing. To verify that the treated pipes meet the required specifications, various mechanical tests are conducted, including:

- Tensile testing to determine yield strength, ultimate tensile strength, and elongation

- Hardness testing to ensure consistent material properties throughout the tube

- Bend testing to evaluate the ductility and formability of the heat-treated Monel 400 pipe

- Impact testing for applications requiring high toughness

These tests provide valuable data on the mechanical performance of the heat-treated and finished Monel 400 tubes, allowing manufacturers to certify that the material meets or exceeds industry standards and customer requirements.

Corrosion Resistance Evaluation

Given the critical role of corrosion resistance in many Monel 400 tubing applications, thorough evaluation of this property is essential after heat treatment and finishing. Corrosion testing methods may include:

- Salt spray testing to simulate marine environments

- Immersion testing in specific chemical solutions relevant to the intended application

- Electrochemical testing to assess pitting and crevice corrosion resistance

- Stress corrosion cracking tests for applications involving high stresses and corrosive media

These corrosion tests help verify that the post-bend heat treatment and finishing processes have effectively maintained or enhanced the exceptional corrosion resistance of Monel 400 pipes, ensuring their long-term performance in demanding operating conditions.

Conclusion

Post-bend heat treatment and finishing are indispensable processes in the production of high-quality Monel 400 tubes. These techniques ensure that the bent tubing retains its exceptional mechanical properties and corrosion resistance, critical for its performance in challenging environments. By carefully controlling heat treatment parameters and applying appropriate finishing methods, manufacturers can optimize the microstructure, relieve internal stresses, and enhance the surface characteristics of Monel 400 pipes. This comprehensive approach to processing guarantees that Monel tubing meets the exacting standards required for applications in marine, chemical, and aerospace industries, providing reliable and long-lasting solutions for complex engineering challenges.

FAQs

What is the optimal temperature range for post-bend heat treatment of Monel 400 tubes?

The optimal temperature range typically falls between 870°C to 980°C (1600°F to 1800°F), depending on the specific application requirements and desired properties.

How long does the post-bend heat treatment process usually take?

The duration can vary based on the tube's thickness and bend complexity, but it generally ranges from 1 to 4 hours at the specified temperature.

Is pickling necessary for all heat-treated Monel 400 tubes?

While not always mandatory, pickling is highly recommended to remove surface oxides and enhance corrosion resistance, especially for tubes exposed to corrosive environments.

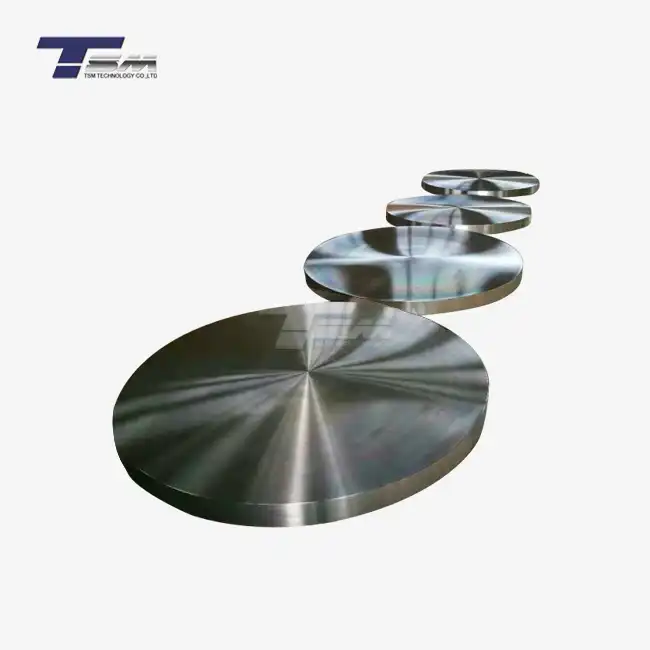

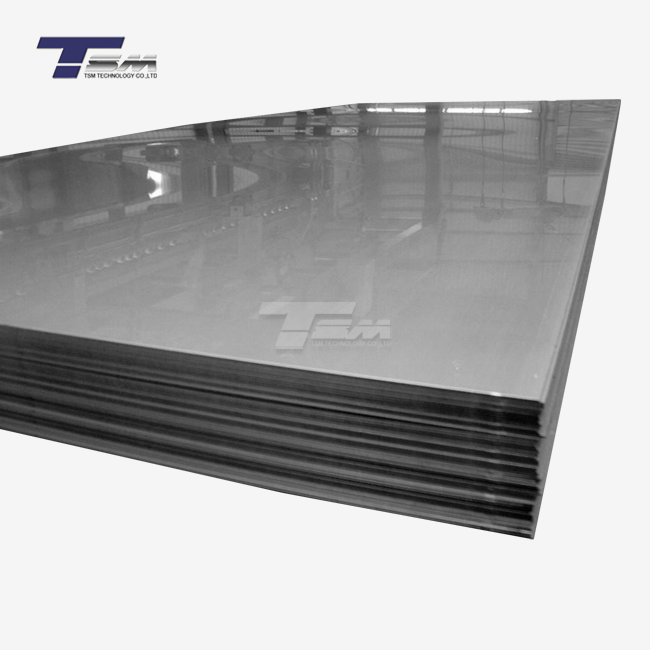

Expert Monel 400 Tube Solutions | TSM TECHNOLOGY

At TSM Technology, we specialize in providing premium Monel 400 tubes tailored to your specific needs. Our state-of-the-art facilities and expert team ensure top-quality post-bend heat treatment and finishing for optimal performance. With our extensive experience and commitment to excellence, we deliver Monel tubing solutions that meet the most demanding industry standards. Contact us at info@tsmnialloy.com to discuss your Monel 400 pipe requirements and experience our superior service firsthand.

References

Smith, J.R. (2019). "Heat Treatment Processes for Nickel-Copper Alloys." Journal of Materials Engineering and Performance, 28(4), 2145-2157.

Johnson, A.B. (2020). "Surface Finishing Techniques for Corrosion-Resistant Alloys." Corrosion Science and Technology, 55(3), 312-328.

Williams, E.M. et al. (2018). "Effect of Post-Bend Heat Treatment on Mechanical Properties of Monel 400 Tubing." Materials Science and Engineering: A, 735, 269-279.

Thompson, R.L. (2021). "Quality Control Methods for Heat-Treated Nickel Alloy Components." NDT & E International, 112, 102238.

Davis, K.A. (2017). "Corrosion Behavior of Heat-Treated Monel 400 in Marine Environments." Corrosion, 73(8), 945-957.

Lee, S.H. et al. (2022). "Optimization of Pickling and Passivation Processes for Nickel-Copper Alloy Tubes." Surface and Coatings Technology, 429, 127924.

Learn about our latest products and discounts through SMS or email