Understanding Incoloy 800 Tube Properties

Composition and Microstructure

Incoloy 800 tubes are composed of a carefully balanced blend of nickel (30-35%), chromium (19-23%), and iron (39.5% minimum). This unique composition results in an austenitic microstructure that contributes to the alloy's remarkable properties. The presence of nickel enhances corrosion resistance and ductility, while chromium forms a protective oxide layer, crucial for high-temperature applications. The iron content helps maintain cost-effectiveness without compromising performance.

Mechanical Characteristics

The mechanical properties of Incoloy 800 piping and Incoloy 800 pipe are impressive across a wide temperature range. At room temperature, these tubes exhibit a tensile strength of approximately 586 MPa (85 ksi) and a yield strength of about 241 MPa (35 ksi). What's particularly noteworthy is that Incoloy 800 maintains substantial strength at elevated temperatures, with a tensile strength of around 241 MPa (35 ksi) at 816°C (1500°F). This retention of strength is crucial for applications involving high-temperature, high-pressure environments.

Thermal Stability

Thermal stability is a hallmark of Incoloy 800 tubing. The alloy's coefficient of thermal expansion is relatively low, about 14.4 µm/m·°C (8.0 µin/in·°F) from 20°C to 100°C. This property minimizes thermal stresses and distortion in applications involving temperature fluctuations. Additionally, the material's thermal conductivity of approximately 11.5 W/m·K at 20°C allows for efficient heat transfer in heat exchanger applications.

Temperature Limits and Performance

Low-Temperature Capabilities

While Incoloy 800 pipes are often associated with high-temperature applications, they also perform admirably at low temperatures. The alloy retains its ductility and toughness down to cryogenic temperatures, making it suitable for applications as low as -100°C (-148°F). This low-temperature capability is particularly valuable in processes involving liquefied gases or in environments with extreme temperature variations.

High-Temperature Resilience

The high-temperature performance of Incoloy 800 tubing is where the alloy truly shines. It maintains structural integrity and resists oxidation up to 816°C (1500°F) in continuous service. At these elevated temperatures, the chromium in the alloy forms a stable, adherent oxide layer that protects against further oxidation. This characteristic makes Incoloy 800 tubes ideal for use in furnace components, heat-treating equipment, and other high-temperature industrial processes.

Creep Resistance

Creep resistance is a critical factor in high-temperature applications, and Incoloy 800 excels in this aspect. The alloy's creep strength remains significant even at temperatures above 540°C (1000°F). For instance, at 649°C (1200°F), Incoloy 800 can withstand a stress of 62 MPa (9 ksi) for 10,000 hours before rupture. This exceptional creep resistance ensures long-term reliability in applications where constant stress at high temperatures is a concern.

Pressure Limits and Applications

Room Temperature Pressure Ratings

At room temperature, Incoloy 800 pipes demonstrate impressive pressure-bearing capabilities. Depending on the tube dimensions, these alloys can handle pressures up to 20.7 MPa (3000 psi). For example, a 25.4 mm (1 inch) outer diameter Incoloy 800 tube with a 2.11 mm (0.083 inch) wall thickness can safely operate at pressures up to 17.2 MPa (2500 psi) at room temperature. It's important to note that these pressure ratings are subject to specific safety factors and should be verified for each application.

Elevated Temperature Pressure Considerations

As temperatures increase, the pressure-bearing capacity of Incoloy 800 tubing naturally decreases. However, the reduction is gradual, allowing for substantial pressure tolerance even at high temperatures. For instance, at 540°C (1000°F), the same 25.4 mm tube mentioned earlier can still withstand pressures up to 11.7 MPa (1700 psi). This combination of high-temperature strength and pressure resistance makes Incoloy 800 pipes invaluable in petrochemical processing and power generation applications.

Fatigue and Cyclic Loading

In applications involving cyclic pressure or temperature changes, fatigue resistance becomes crucial. Incoloy 800 tubes exhibit excellent fatigue strength, particularly in high-temperature environments. The alloy can withstand over 10^7 cycles at a stress amplitude of 241 MPa (35 ksi) at room temperature. Even at elevated temperatures, such as 593°C (1100°F), Incoloy 800 maintains significant fatigue resistance, ensuring longevity in dynamic, high-stress environments like heat exchangers and boiler tubes.

Conclusion

Incoloy 800 tubes stand out for their exceptional performance across a wide range of temperatures and pressures. Their ability to maintain structural integrity and resist corrosion from -100°C to 816°C, coupled with impressive pressure tolerances up to 20.7 MPa at room temperature, makes them indispensable in various industrial applications. The alloy's unique composition ensures thermal stability, creep resistance, and fatigue strength, particularly crucial in high-temperature, high-pressure environments. For industries requiring reliable, long-lasting tubing solutions in extreme conditions, Incoloy 800 pipes continue to be an excellent choice, offering a balance of performance, durability, and cost-effectiveness.

FAQs

What are the key advantages of using Incoloy 800 tubes?

Incoloy 800 tubes offer excellent resistance to high-temperature oxidation, corrosion, and carburization. They maintain mechanical properties at elevated temperatures and are suitable for a wide range of industrial applications.

How does the pressure rating of Incoloy 800 pipes change with temperature?

As the temperature increases, the pressure rating of Incoloy 800 pipes decreases. However, they maintain significant pressure tolerance even at high temperatures, making them suitable for high-temperature, high-pressure environments.

Can Incoloy 800 tubing be used in cryogenic applications?

Yes, Incoloy 800 tubing retains its ductility and toughness at low temperatures, making it suitable for applications down to -100°C (-148°F).

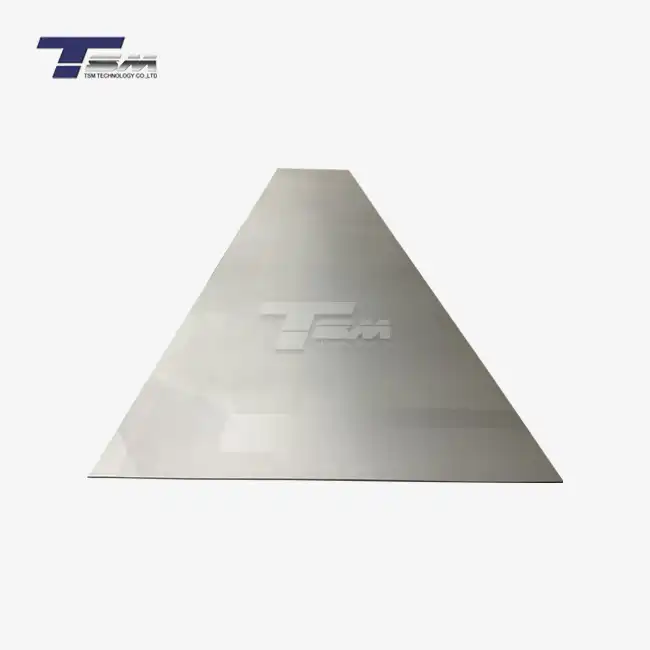

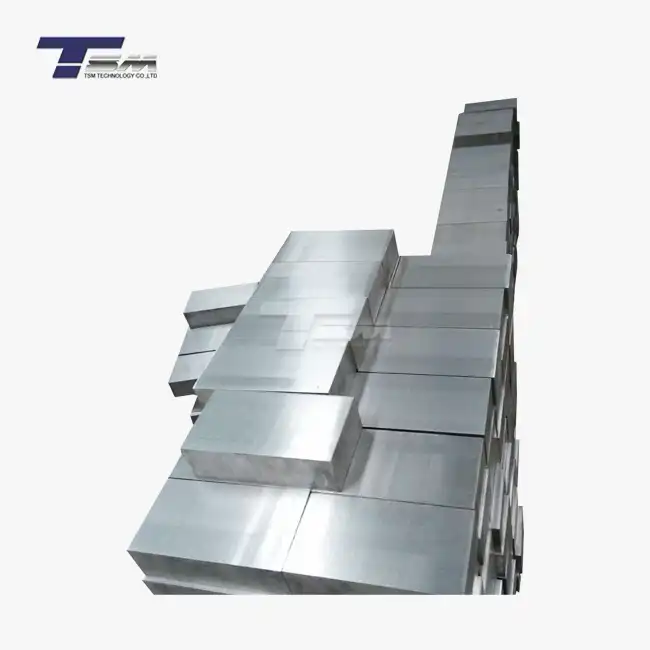

Superior Incoloy 800 Tube Solutions | TSM TECHNOLOGY

At TSM Technology, we specialize in manufacturing high-quality Incoloy 800 tubes that meet and exceed industry standards. Our state-of-the-art facilities, equipped with 8 production lines and over 100 advanced machines, ensure precision and consistency in every tube we produce. With a monthly supply capacity of 300 tons and customization options available, we're your reliable partner for all Incoloy 800 tubing needs. For expert advice or to request a quote, contact us at info@tsmnialloy.com.

References

ASTM International. (2020). ASTM B163 - Standard Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes.

Special Metals Corporation. (2019). INCOLOY alloy 800H & 800HT Technical Data Sheet.

ASM International. (2018). ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys.

Haynes International. (2021). High-Temperature Alloys: Mechanical Properties and Applications.

American Society of Mechanical Engineers. (2019). ASME Boiler and Pressure Vessel Code, Section II: Materials.

Nickel Institute. (2020). High Temperature Characteristics of Stainless Steels and Nickel Alloys.