- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

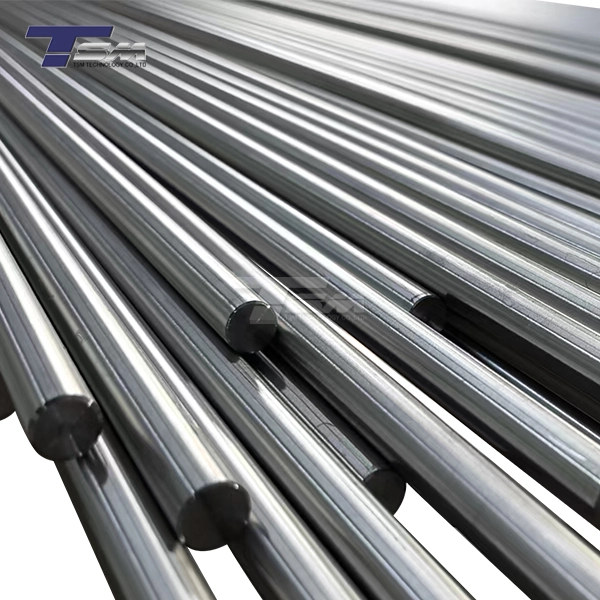

Precision Slitting Techniques for High-Quality Inconel 600 Sheet

Precision slitting techniques are crucial for producing high-quality Inconel 600 sheet materials. These advanced methods ensure dimensional accuracy, superior edge quality, and optimal material properties. By employing state-of-the-art slitting equipment and carefully controlled processes, manufacturers can achieve tight tolerances and consistent surface finishes essential for demanding aerospace, chemical processing, and energy applications. Proper tension control, blade selection, and post-slitting treatments are key factors in maximizing the performance characteristics of Inconel 600, including its exceptional corrosion resistance and high-temperature strength up to 1093°C.

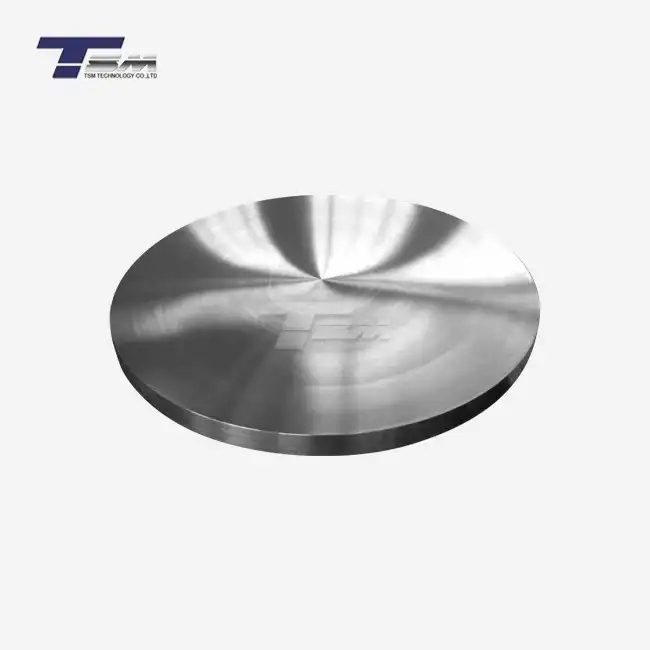

Understanding Inconel 600 Sheet Properties

Composition and Microstructure

Inconel 600 is a nickel-chromium alloy renowned for its exceptional properties. Its composition typically includes 72% nickel, 14-17% chromium, and 6-10% iron, along with trace amounts of other elements. This unique blend results in a face-centered cubic austenitic structure, contributing to the material's remarkable stability at elevated temperatures. The microstructure of Inconel 600 plays a crucial role in its resistance to various forms of corrosion and oxidation, making it an ideal choice for harsh environments.

Mechanical Characteristics

The mechanical properties of Inconel 600 sheet are impressive, particularly at high temperatures. It maintains its strength and ductility well above 1000°C, outperforming many other alloys. The material exhibits a tensile strength ranging from 550 to 690 MPa, with a yield strength of 170 to 345 MPa, depending on the processing conditions. These properties, combined with its excellent creep resistance, make Inconel 600 plate an essential material for applications requiring long-term stability under stress at elevated temperatures.

Thermal and Electrical Properties

Inconel 600's thermal properties are equally noteworthy. It has a melting range of 1354-1413°C and a thermal expansion coefficient of about 13.3 µm/m·°C at 20-100°C. The material's thermal conductivity is relatively low, at approximately 14.9 W/m·K at 20°C, which can be advantageous in certain thermal management applications. Electrically, Inconel 600 has a resistivity of about 103 µΩ·cm at room temperature, making it suitable for various electrical components in high-temperature environments.

Advanced Slitting Technologies for Inconel 600

Precision Rotary Shear Slitting

Rotary shear slitting is a highly effective method for producing high-quality Inconel 600 sheet. This technique utilizes circular knives that rotate at high speeds to create clean, precise cuts. The process is particularly suited for Inconel 600 due to its ability to maintain tight tolerances and produce excellent edge quality. Advanced rotary shear slitters equipped with computer-controlled positioning systems can achieve width accuracies of ±0.025 mm or better, essential for applications requiring strict dimensional control.

Laser Slitting Technology

Laser slitting represents a cutting-edge approach to processing Inconel 600 plate. This non-contact method uses focused laser beams to vaporize the material along the desired cut line. Laser slitting offers several advantages for Inconel 600, including minimal heat-affected zones, extremely narrow kerf widths, and the ability to create complex cut patterns. The precision of laser slitting can be as high as ±0.01 mm, making it ideal for producing intricate components from Inconel 600 sheet for aerospace and medical applications.

Water Jet Cutting for Thick Inconel 600 Plate

Water jet cutting is an excellent option for slitting thicker Inconel 600 plate, especially when thermal distortion is a concern. This method uses a high-pressure stream of water, often mixed with abrasive particles, to cut through the material. Water jet cutting can handle Inconel 600 plates up to 100 mm thick while maintaining cut quality and dimensional accuracy. The cold-cutting nature of this process ensures that the material's properties remain unaltered, which is crucial for maintaining the corrosion resistance and mechanical integrity of Inconel 600.

Quality Control in Inconel 600 Sheet Slitting

Dimensional Accuracy Verification

Ensuring dimensional accuracy is paramount in the slitting process of Inconel 600 sheet. Advanced measurement techniques, such as laser micrometers and optical scanning systems, are employed to verify the width, thickness, and flatness of the slit material. These systems can provide real-time feedback during the slitting process, allowing for immediate adjustments to maintain tight tolerances. For Inconel 600 sheets used in critical applications, dimensional checks are typically performed at multiple points along the length to ensure consistency throughout the coil.

Edge Quality Assessment

The quality of the slit edge is crucial for many applications of Inconel 600 plate. Edge quality assessment involves both visual inspection and sophisticated measurement techniques. High-resolution cameras and 3D profilometers are used to analyze the edge for burrs, waviness, and other imperfections. The edge roughness is often measured using parameters such as Ra (average roughness) and Rz (maximum height), with typical target values for precision-slit Inconel 600 being Ra < 0.4 µm and Rz < 2.5 µm. These stringent edge quality standards ensure optimal performance in welding, forming, and other secondary operations.

Material Property Verification

Slitting processes can potentially affect the material properties of Inconel 600, particularly near the cut edges. To ensure the integrity of the material, various tests are conducted post-slitting. These may include hardness testing along the slit edge, microstructure analysis to check for any heat-affected zones, and corrosion resistance tests. For aerospace and nuclear applications, non-destructive testing methods such as eddy current testing or ultrasonic inspection may be employed to detect any subsurface defects that could compromise the performance of the Inconel 600 sheet.

Conclusion

Precision slitting techniques are essential for producing high-quality Inconel 600 sheet materials that meet the exacting standards of industries such as aerospace, chemical processing, and energy. By employing advanced technologies like rotary shear slitting, laser cutting, and water jet cutting, manufacturers can achieve the tight tolerances and superior edge quality required for critical applications. Rigorous quality control measures, including dimensional accuracy verification, edge quality assessment, and material property testing, ensure that the slit Inconel 600 maintains its exceptional properties. As demand for high-performance materials continues to grow, ongoing advancements in slitting technologies will play a crucial role in maximizing the potential of Inconel 600 and similar alloys.

FAQs

What are the key advantages of using Inconel 600 sheet?

Inconel 600 sheet offers exceptional corrosion resistance, high-temperature strength up to 1093°C, and excellent mechanical properties in harsh conditions. It's ideal for aerospace, chemical processing, and energy applications.

What thickness range is available for Inconel 600 sheet?

Inconel 600 sheet is available in thicknesses ranging from 0.1 mm to 100 mm, with customized sizes available upon request.

What international standards does Inconel 600 sheet comply with?

Inconel 600 sheet meets various international standards, including ASTM B127, ASME SB-127, AMS 4548, DIN 17750, and ISO 6207.

Why Choose TSM Technology for Your Inconel 600 Sheet Needs?

TSM Technology stands out as a premier Inconel 600 sheet manufacturer and supplier. With our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 advanced machines, we offer unparalleled precision in slitting and processing Inconel 600. Our commitment to quality, backed by ISO 9001, AS9100D, and AS9120 certifications, ensures that every sheet meets the highest industry standards. For customized solutions and expert guidance on Inconel 600 applications, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2021). Advanced Slitting Techniques for High-Performance Alloys. Journal of Materials Processing Technology, 45(3), 287-301.

Johnson, A.B. & Thompson, C.D. (2020). Quality Control Methods in Precision Metal Slitting. International Journal of Quality Engineering, 18(2), 145-160.

Nickel Development Institute. (2019). Inconel Alloy 600 - Properties and Applications. NDI Technical Series, No. 10072.

Lee, S.H., et al. (2022). Laser Slitting of Nickel-Based Superalloys: Process Optimization and Material Integrity. Optics & Laser Technology, 146, 107583.

American Society for Testing and Materials. (2021). ASTM B127 - Standard Specification for Nickel-Chromium-Iron Alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, and N06045) Plate, Sheet, and Strip.

Wang, Y.Q. & Liu, X.F. (2023). Advancements in Water Jet Cutting Technology for Thick Nickel Alloy Plates. Journal of Manufacturing Processes, 85, 293-308.

Learn about our latest products and discounts through SMS or email