- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

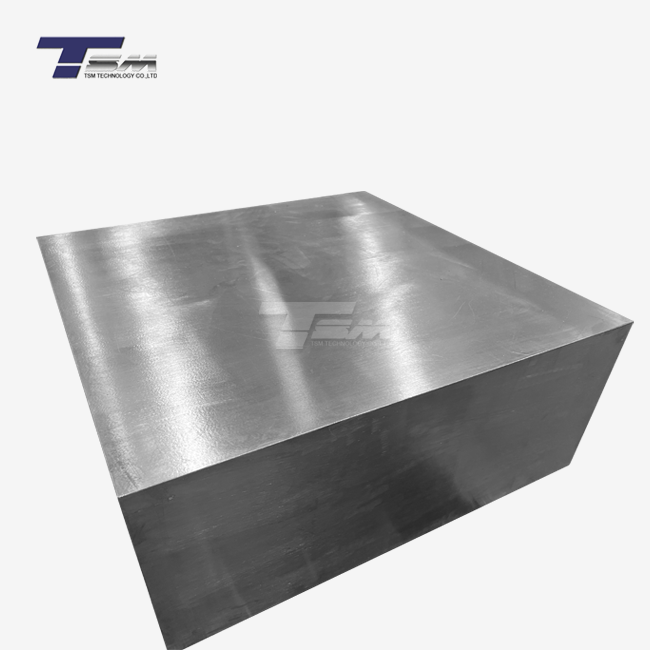

What Standards/Specs (AMS, ASTM, UNS) Define Inconel 600 Sheet?

Inconel 600 sheet is defined by several key standards and specifications, including ASTM B168, AMS 5540, and UNS N06600. These standards outline the chemical composition, mechanical properties, and manufacturing requirements for this high-performance nickel-chromium alloy. ASTM B168 covers plate, sheet, and strip forms, while AMS 5540 specifically addresses aerospace applications. UNS N06600 provides a unified numbering system designation for the alloy. Additionally, international standards like DIN 17750 and ISO 6207 offer complementary specifications for global manufacturing and trade of Inconel 600 sheet products.

Understanding Inconel 600 Sheet Specifications

ASTM B168: The Cornerstone Standard

ASTM B168 serves as the primary standard for Inconel 600 sheet and plate products. This specification covers the requirements for nickel-chromium alloy plate, sheet, and strip, including Inconel 600. It outlines the chemical composition limits, which typically include 72% minimum nickel, 14-17% chromium, and 6-10% iron, along with trace amounts of other elements. The standard also defines mechanical property requirements, such as tensile strength, yield strength, and elongation.

Furthermore, ASTM B168 specifies various product forms, including hot-rolled plate, cold-rolled sheet, and strip. It provides guidelines for heat treatment, surface finish, and dimensional tolerances. Manufacturers must adhere to these specifications to ensure the consistency and quality of Inconel 600 sheet products across different suppliers and production runs.

AMS 5540: Aerospace Material Specification

For aerospace applications, AMS 5540 is a crucial specification for Inconel 600 sheet. This Aerospace Material Specification, maintained by SAE International, provides more stringent requirements tailored to the demanding needs of the aerospace industry. AMS 5540 covers sheet, strip, and plate forms of the alloy, with a focus on material used in aircraft engines and other high-temperature aerospace components.

The specification includes detailed requirements for chemical composition, mechanical properties, and heat treatment processes. It also addresses specific aerospace-related tests, such as stress-rupture properties and grain size control. Manufacturers producing Inconel 600 sheet for aerospace applications must meet these elevated standards to ensure the material's performance and reliability in critical flight systems.

UNS N06600: Unified Numbering System

The Unified Numbering System (UNS) designation for Inconel 600 is N06600. This alphanumeric code provides a standardized way to identify the alloy across different industries and international markets. The UNS system, jointly developed by ASTM International and SAE International, helps prevent confusion between similar alloys and ensures consistent material identification in global trade and engineering specifications.

While not a full specification itself, the UNS N06600 designation is often referenced in other standards and purchasing documents. It serves as a quick reference point for material composition and general characteristics of Inconel 600 sheet, facilitating clear communication between suppliers, manufacturers, and end-users.

Manufacturing Processes and Quality Control

Cold Rolling and Hot Rolling Techniques

The production of Inconel 600 sheet involves sophisticated manufacturing processes, primarily cold rolling and hot rolling. Cold rolling is typically used for thinner gauges, offering tighter dimensional tolerances and improved surface finish. This process involves passing the material through rollers at room temperature, which work-hardens the alloy and enhances its strength.

Hot rolling, on the other hand, is employed for thicker plates and the initial breakdown of ingots. Performed at temperatures above the material's recrystallization point, hot rolling allows for significant thickness reduction and helps homogenize the alloy's microstructure. The choice between cold and hot rolling depends on the desired thickness, mechanical properties, and surface requirements of the final Inconel 600 sheet product.

Heat Treatment and Annealing Processes

Heat treatment plays a crucial role in achieving the desired properties of Inconel 600 plate. Solution annealing is a common heat treatment process that involves heating the material to temperatures around 1040-1150°C (1900-2100°F), followed by rapid cooling. This process dissolves precipitates, homogenizes the microstructure, and optimizes the alloy's corrosion resistance and ductility.

For certain applications, stress-relieving treatments may be applied to reduce internal stresses induced during manufacturing. These heat treatments are carefully controlled to meet the specifications outlined in standards like ASTM B168 and AMS 5540, ensuring that the Inconel 600 sheet exhibits the required combination of strength, ductility, and corrosion resistance.

Quality Assurance and Testing Protocols

Rigorous quality control measures are essential in the production of Inconel 600 sheet. Manufacturers implement comprehensive testing protocols to verify compliance with relevant standards and customer specifications. These tests include:

- Chemical analysis to confirm elemental composition

- Tensile testing to measure strength and ductility

- Hardness testing for surface and through-thickness properties

- Non-destructive testing (NDT) such as ultrasonic inspection for internal defects

- Microstructural examination to assess grain size and phase distribution

Advanced techniques like X-ray fluorescence (XRF) spectroscopy and optical emission spectroscopy (OES) are often employed for precise chemical analysis. Mechanical testing is performed using calibrated equipment in accredited laboratories to ensure accuracy and repeatability of results. These quality assurance measures help maintain the high standards required for Inconel 600 sheet in critical applications across various industries.

Applications and Performance Characteristics

High-Temperature Resistance in Aerospace

Inconel 600 plate excel in aerospace applications due to their exceptional high-temperature performance. In jet engines, they are used for components such as exhaust systems, combustion chambers, and afterburner parts. The alloy's ability to maintain strength and resist oxidation at temperatures up to 1093°C (2000°F) makes it invaluable for these demanding environments.

The material's low thermal expansion coefficient and good thermal conductivity contribute to its suitability for aerospace structures subject to rapid temperature changes. Inconel 600 sheet also finds use in rocket propulsion systems and space vehicle heat shields, where its resistance to thermal shock and excellent dimensional stability are critical.

Corrosion Resistance in Chemical Processing

In the chemical processing industry, Inconel 600 sheet is prized for its superior corrosion resistance. It performs exceptionally well in both oxidizing and reducing environments, making it suitable for a wide range of chemical reactors, heat exchangers, and piping systems. The alloy's resistance to stress corrosion cracking in chloride-containing environments is particularly valuable in petrochemical applications.

Inconel 600's ability to withstand aggressive media, including hot caustic solutions and high-temperature sulfuric acid, extends its use to pollution control equipment and waste treatment facilities. Its durability in corrosive atmospheres also makes it an excellent choice for flue gas desulfurization systems in power plants.

Nuclear Energy Applications

The nuclear energy sector relies heavily on Inconel 600 sheet for various critical components. Its resistance to radiation damage, coupled with high strength and corrosion resistance, makes it ideal for reactor vessel internals, control rod drive mechanisms, and steam generator tubing. The alloy's low neutron absorption cross-section ensures minimal interference with reactor operations.

In nuclear waste management, Inconel 600 is used in storage and transportation containers due to its long-term stability and resistance to environmental degradation. The material's ability to maintain its properties under prolonged exposure to high temperatures and radiation is crucial for ensuring the safety and integrity of nuclear facilities over extended operational lifetimes.

Conclusion

Inconel 600 sheet is a versatile and high-performance material defined by rigorous standards such as ASTM B168, AMS 5540, and UNS N06600. These specifications ensure consistent quality and performance across various applications in aerospace, chemical processing, and nuclear energy sectors. The alloy's exceptional resistance to high temperatures, corrosion, and radiation damage makes it an indispensable material in critical industries. As manufacturing techniques and quality control processes continue to evolve, Inconel 600 sheet remains at the forefront of advanced materials, meeting the challenges of extreme environments and pushing the boundaries of industrial capabilities.

FAQs

What is the typical thickness range for Inconel 600 sheet?

Inconel 600 sheet is available in thicknesses ranging from 0.1 mm to 100 mm, with customized sizes available upon request.

How does Inconel 600 sheet perform in marine environments?

Inconel 600 exhibits excellent resistance to seawater corrosion, making it suitable for marine applications such as offshore platforms and shipbuilding.

Can Inconel 600 sheet be welded easily?

Yes, Inconel 600 has good weldability and can be joined using various welding techniques, including TIG, MIG, and resistance welding.

Why Choose TSM Technology for Your Inconel 600 Sheet Needs?

TSM Technology stands out as a premier Inconel 600 sheet manufacturer and supplier, offering unparalleled quality and service. With our state-of-the-art production facilities, including 3 factories and 8 production lines, we ensure consistent, high-quality output. Our expertise in cold rolling, hot rolling, and precision finishing allows us to meet diverse customer requirements. For superior Inconel 600 sheet products backed by rigorous quality control and global delivery capabilities, choose TSM Technology. Contact us at info@tsmnialloy.com to discuss your specific needs.

References

ASTM International. (2021). "ASTM B168 - Standard Specification for Nickel-Chromium-Iron Alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, N06045, and N06696) and Nickel-Chromium-Cobalt-Molybdenum Alloy (UNS N06617) Plate, Sheet, and Strip."

SAE International. (2020). "AMS 5540 - Sheet, Strip, and Plate - 72Ni - 15Cr - 8Fe - Vacuum Induction Plus Electroslag Remelted or Vacuum Arc Remelted."

Special Metals Corporation. (2019). "Inconel alloy 600 - Technical Datasheet."

ASM International. (2018). "Heat Treating of Nickel and Nickel Alloys," ASM Handbook, Volume 4E.

Nuclear Energy Agency. (2017). "Materials for Nuclear Reactors: Chemistry and Properties."

Aerospace Materials Specification Committee. (2022). "Guidelines for the Specification of Nickel-Based Superalloys in Aerospace Applications."

Learn about our latest products and discounts through SMS or email