- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Selecting the Right Nickel Alloy Fastener for Chemical Processing.

To choose the right nickel metal fastener for chemical processing, you need to understand how to handle harsh working conditions and locations prone to corrosion. Nickel fasteners work better than regular materials because they are very strong, don't rust, and stay stable at high temperatures, all of which are important for chemical uses. As part of the selection process, specific metal compositions, operating conditions, and practical needs are evaluated to ensure that the fasteners perform well and remain reliable over time in harsh chemical processing environments.

Understanding Nickel Alloy Fasteners in Chemical Processing

Some of the hardest situations for fastener materials are found in places where chemicals are processed. It is important for buying workers to understand the basics of nickel alloy fasteners if they want to find reliable solutions that can handle harsh chemicals, changes in temperature, and mechanical stress.

Defining Nickel Alloy Fasteners and Their Composition

An important type of industrial part is nickel alloy screws, which are made from high-performance metals that contain a lot of nickel. Alloying elements like chromium, molybdenum, iron, and copper are often used in these screws to improve their qualities. While the nickel base naturally resists corrosion, the addition of other elements improves the mechanical qualities and makes the material more suitable for use in chemical processes.

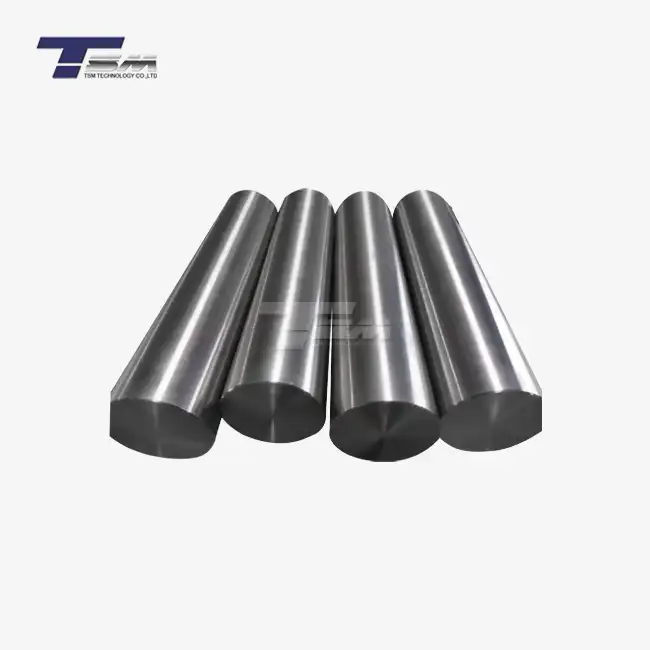

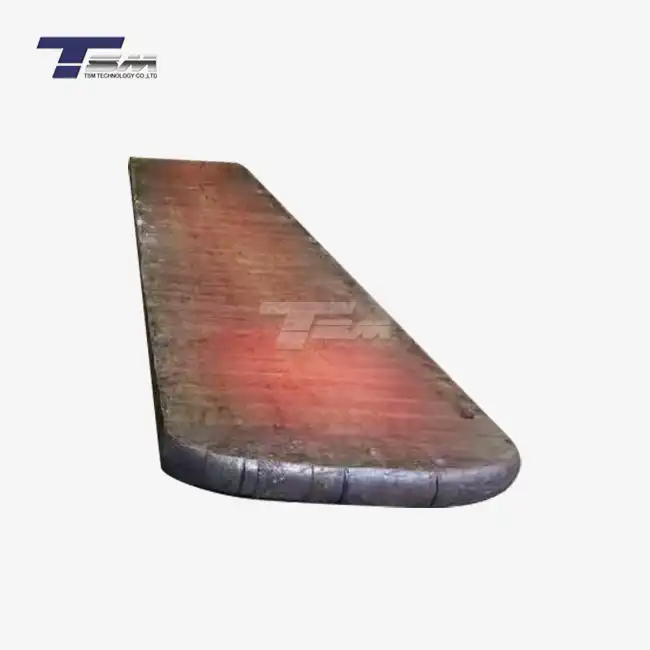

Nickel metal fasteners made today come in many shapes and sizes, such as bolts, nuts, screws, washers, and special fasteners made for chemical handling equipment. During the production process, precise metallurgical control is used to make sure that the material qualities and dimensions stay the same, which is important for important uses.

Common Nickel Alloys in Chemical Processing Applications

Chemical processing plants use several tried-and-true nickel metal methods, each with its own benefits for certain tasks. Inconel alloys work very well in situations where oxygen is present at high temperatures, keeping their strength and not oxidizing at those high temps. These metals work really well in reactor vessels, heat exchanges, and high-temperature pipe systems that are put through a lot of stress from changing temperatures and chemicals.

When used in reducing conditions, monel metals work very well and are very resistant to hydrofluoric acid and other harsh chemicals. The high amount of nickel mixed with the copper gives it special rusting properties that make it perfect for chemical processing in the ocean and other underwater uses. Hastelloy metals are the best choice for the harshest chemical environments because they work very well in both oxidizing and reducing situations and are compatible with a wide range of chemicals.

Key Benefits and Performance Characteristics

There are more performance benefits of nickel alloy screws in chemical processes than just not rusting. The functional stability of these materials stays the same across a wide range of temperatures, from very cold temperatures to process temperatures above 1000°F. Strength, ductility, and toughness work together to make sure that the material works well under mechanical stress, heat cycles, and dynamic loading.

Different types of nickel alloy have very different magnetic qualities. Some compositions are nonmagnetic, which is needed for certain uses. This quality is especially important for chemical processing equipment that needs non-magnetic fixings for monitoring or process control tasks that need to keep magnetic interference to a minimum.

Key Factors to Consider When Choosing Nickel Alloy Fasteners

When choosing the right nickel fasteners, you need to carefully consider a lot of technical factors that have a direct effect on their performance and service life. When buying workers understand these factors, they can make smart choices that balance performance needs with cost concerns.

Corrosion Resistance and Chemical Compatibility

Different types of corrosion can happen to bolts in chemical processing settings. These include uniform corrosion, pitting, crevice corrosion, and stress corrosion cracking. Each type of nickel alloy has different chemical resistance properties, so the features of the material must be carefully matched to the circumstances in which it will be used.

Inconel 625 is very resistant to pitting and crevice corrosion in chloride-containing settings. This means it can be used in seawater and in chemical processes that use chlorine. Hastelloy C-276 works better in mixed chemical conditions and reducing acids than other metals that might selectively corrode or break down. When choosing a material, it's important to think about more than just the main chemical that will be exposed. Possible contaminants, changes in temperature, and changes in concentration can all affect how the material will corrode.

To stop rust from speeding up, it's important to think carefully about the galvanic interaction between fastener materials and nearby equipment parts. Nickel alloys usually behave well in galvanic pairs, but certain mixtures with other materials should be looked at to make sure the long-term strength of the whole assembly.

Mechanical Properties and Temperature Performance

Chemical processing screws need to have certain mechanical properties, such as strength, ductility, wear resistance, and creep resistance, based on the conditions of use. Materials that stay strong and don't creep bend over long periods of time are needed for high-temperature uses. For uses at room temperature, corrosion protection may be more important than keeping enough mechanical qualities for assembly and operating loads.

Temperature changing causes thermal stress that can weaken fasteners through different levels of expansion, wear and tear, or changes in the metal's structure. Most nickel alloys are very stable at high temperatures, but some types may go through precipitation hardening or other metallurgical changes that affect their long-term qualities. By knowing about these features, you can choose the right metals for different temperature ranges and service needs.

Design and Installation Considerations

Chemical processing equipment needs to be compatible with the design factors of the fastener, such as the thread form, head arrangement, and size limits. Standard fastener designs may need to be changed to meet unique sealing needs, accessibility issues, or standard repair processes in chemical processing plants.

Installation factors include the amount of power needed, the resistance to galling, and the assembly steps that keep the parts from breaking during installation. In some situations, nickel metals can blister, which means they need to be properly lubricated, have their surfaces treated, or be installed in a certain way to make sure the parts fit together correctly without getting damaged.

Procurement Considerations for Nickel Alloy Fasteners in B2B Chemical Industries

To make sure you have a steady supply of important parts like nickel fasteners, you need to carefully check the skills, quality systems, and shipping performance of any suppliers you're considering. Because these products are so specialized, they need to come from sources who know a lot about chemical processing and have a track record of success.

Supplier Qualification and Certification Requirements

For chemical processing, you need fasteners that are made to strict quality standards and have full approval and material tracking. Suppliers must show that they follow industry standards like ASTM, ASME, and API guidelines and keep strong quality management systems that are approved to ISO 9001 or similar standards.

With more than 14 years of experience making nickel alloy screws for chemical processing, TSM Technology is a great example of a skilled seller. We have three factories that together run eight production lines with more than 70 precise machines. This means that we can make anywhere from 100,000 to 300,000 pieces at a time to meet the needs of different projects. We follow ASTM, DIN, JIS, BS, and GB/T standards and offer EN10204 3.1/3.2 approval and third-party inspection records to make sure that all of our materials can be tracked back to their original source.

Supplier approval is important for more than just being able to make things. It's also important for technical help, application knowledge, and quick customer service. Qualified suppliers help with choosing the right materials by giving expert advice, making custom solutions for specific needs, and keeping track of supplies to meet ongoing upkeep and growth needs.

Cost Analysis and Total Ownership Considerations

When purchasing nickel alloy fasteners, the original cost of the materials must be weighed against the long-term practical benefits, such as longer service life, less upkeep, and higher dependability. Although nickel alloys are more expensive than other materials, they are often better value for money in chemical handling tasks that require a lot of work.

When fasteners fail in situations where they could cause unexpected downtime, safety issues, or environmental releases, service life becomes even more important. With the right nickel alloy fasteners, you can go longer between service times, which can cut lifetime costs by a large amount while also making the system more reliable and safer.

Buying in bulk can save you money and make sure you have enough supplies for planned maintenance and repairs that need to be done right away. With custom manufacturing choices, fastener designs can be tweaked to work best in certain situations. This could lower the cost of installation and make the hardware work better than with standard setups.

Real-World Applications and Case Studies of Nickel Alloy Fasteners in Chemical Processing

In chemical processing uses, real-world experience with nickel fasteners shows how important it is to choose the right material. Real-life case studies are a great way to learn about how fasteners work, how to choose them, and what can be learned from both successful and unsuccessful uses.

Marine Chemical Processing Facility Case Study

A big petrochemical plant that uses seawater as a fuel had a problem where normal stainless steel fasteners kept breaking in important pipe systems. When chloride, high temperatures, and mechanical stress came together, they made it easy for stress corrosion cracking to happen and for standard rivets to break early.

After looking at the working conditions, it became clear that the screws needed to be more resistant to chloride stress corrosion cracking and keep their power at temperatures close to 400°F. When choosing materials, Inconel 625 fasteners were chosen because they have been used successfully in similar situations before and have a lot of rust testing data that supports their long-term dependability in chloride-containing settings.

When Inconel 625 screws were used, problems stopped happening over and over again, and maintenance checks went from being done every three months to being done once a year. Because there was less repair work to do, no unplanned shutdowns, and better safety performance, the improved dependability saved a lot of money. This example shows how valuable high-quality fastener materials can be in tough chemical handling situations.

High-Temperature Reactor Application

A company that processes chemicals and makes specialty chemicals needed screws for use in reactor vessels that work at temperatures close to 800°F in oxidizing chemical conditions. Standard high-temperature stainless steels were chosen as the first materials, but they broke down quickly and lost their power, so they had to be replaced often and raised safety issues.

Based on engineering research, it was found that the chemicals in the environment needed materials that could keep their strength at high temperatures and not oxidize. Hastelloy X became the best choice after a lot of research into its properties at high temperatures and its track record of success in similar chemical processing tasks.

Long-term performance tracking proved that the new nickel fasteners worked, as the fasteners stayed together for long amounts of time without showing any signs of wear or weakness. The better performance let the working temperatures go up and the process work more efficiently, all while keeping safety limits and reliability standards the same.

Company Introduction and Product & Service Information

Today, TSM Technology is one of the biggest companies that makes and sells high-performance nickel metal screws that are designed to work with chemicals. Our extensive knowledge comes from having worked in precision engineering for over 14 years, during which time we have become a reliable partner for important fastener uses in the toughest industrial settings.

Manufacturing Capabilities and Quality Assurance

Our manufacturing infrastructure includes three sites that are placed in smart ways and run eight specialized production lines with more than 70 high-precision machines. Due to our large production capacity, we can meet the needs of a wide range of customers by producing anywhere from 100,000 to 300,000 pieces at a time. We can also adapt to special requests and meet fast shipping needs.

Quality control is very important to us, and our professional quality control team makes sure that every nickel metal fastener meets strict testing standards. We strictly follow international standards like ASTM, DIN, JIS, BS, and GB/T. We also provide full certification paperwork like EN10204 3.1/3.2 certificates and third-party inspection records to make sure that all of our materials can be tracked back to their original source.

Our selection of products includes a wide range of fastener types, such as bolts, nuts, washers, and unique parts made from high-quality nickel alloys like Hastelloy, Inconel, Inconel, and Monel. Sizes run from M2.5 to M32, and custom sizes are also possible. Lengths from 1mm to 1990mm can be used for almost any purpose in chemical handling equipment.

Service Excellence and Customer Support

Customer support includes more than just delivering the product. It also includes professional advice, help with applications, and ongoing service support for the whole duration of the product. Customers can try and evaluate free samples before placing large orders, and our low minimum order number of just 100 pieces makes our products available for both big and small projects.

Our delivery performance shows how much we care about our customers' happiness. Lead times range from 10 to 25 days, based on the difficulty and quantity of the order. Different customers and the needs of foreign trade can be met by offering flexible payment terms like T/T, L/C, PayPal, and Western Union. Our reliable shipping to chemical production plants around the world is made possible by our global shipping capabilities.

Conclusion

When choosing the right nickel fasteners for chemical processing, you need to think carefully about how well it resists corrosion, its mechanical qualities, how well it works at high temperatures, and how well it meets the needs of your unique application. Nickel alloys are more expensive than other metals, but their better performance makes up for it by lasting longer, being more reliable, and being safer in harsh chemical conditions. To choose the right material, you need to know about the specific working conditions, look at the properties of the alloy, and work with experienced providers who can give you technical advice and reliable delivery.

FAQ

A lot of people have questions about nickel metal screws, which shows how specialized they are and how important it is to choose the right ones for chemical processing jobs. These commonly asked questions cover important technical and purchasing issues that affect choices about what materials to use.

1.How do nickel alloy fasteners compare to stainless steel in chemical processing?

When it comes to harsh chemical settings, nickel alloy screws work better than stainless steel. This is especially true when standard stainless steel types can't handle high temperatures, serious corrosion, or certain chemical exposures. For light service conditions, stainless steel fasteners might be enough, but nickel alloys are needed for important uses that need to be very reliable and last a long time.

Nickel alloys are more resistant to corrosion because they have more nickel in them and other alloying elements that make them resistant to certain types of corrosion. Nickel metals also work better at high temperatures than stainless steels because they stay strong and don't rust at temperatures where stainless steels break down.

2.What methods validate corrosion resistance for specific applications?

Validating corrosion resistance in the lab using standard test methods that mimic real-life working conditions is part of the process. Some common methods are immersing the part in the right chemical medium, using electricity to check the rate of rusting, and putting the part through stress corrosion cracking tests. Published rust data and experience in the field help to back up choices about which materials to use.

TSM Technology offers full material certification, which includes chemical composition analysis, mechanical property proof, and corrosion resistance documents to help customers choose and qualify materials. Our expert team helps customers figure out if a material is right for a certain job by looking at the working conditions and the job's performance needs.

3.What are typical lead times for custom fastener orders?

Standard customizations usually take between 10 and 25 days, but they can take longer depending on the complexity, amount, and availability of the material. Lead times may be longer for complicated designs that need custom tools or a lot of testing, but rush orders can usually be met by giving them priority ordering and quick processing.

When planning for custom fastener needs, you should think about both normal wait times and possible delays that could happen because of a lack of materials or a complicated manufacturing process. Getting in touch with suppliers early on in the planning stages of a project helps optimize shipping schedules and find possible time limits.

Contact Us

Chemical processing workers are welcome to come in for a personalized consultation and product review at TSM Technology to experience the better performance and dependability of our nickel fasteners. Our technical experts are ready to help you choose the right material, get advice on how to use it, and make special manufacturing solutions that meet your exact chemical processing needs. Email our team at info@tsmnialloy.com to talk about the fasteners you need and to ask for free samples to test and evaluate. As a reliable nickel fasteners maker with more than 14 years of experience, we offer full support from the first meeting to delivery and ongoing service.

References

Davis, J.R. "Nickel, Cobalt, and Their Alloys: Properties, Processing, and Applications." ASM International Materials Handbook, 2000.

American Society for Testing and Materials. "Standard Specification for Nickel-Chromium-Molybdenum-Columbium Alloy Rod and Bar." ASTM B564-19, 2019.

Rebak, R.B. "Corrosion Resistance of Nickel Alloys in Chemical Processing Environments." Materials and Corrosion Engineering Handbook, 2018.

National Association of Corrosion Engineers. "Selection Guidelines for Nickel Alloys in Chemical Process Industries." NACE Publication 35105, 2017.

Metals Handbook Committee. "Fasteners for High-Temperature Chemical Processing Applications." ASM Handbook Volume 13A: Corrosion Fundamentals, Testing, and Protection, 2019.

Chemical Processing Magazine. "Best Practices for Fastener Material Selection in Corrosive Environments." Industrial Maintenance and Plant Operation Guide, 2020.

Learn about our latest products and discounts through SMS or email

_1739071581132.webp)