Understanding Monel Tube Specifications and Quality Standards

Composition and Properties of Monel Alloys

Monel is a family of nickel-copper alloys known for their exceptional corrosion resistance and strength. The most common grade, Monel 400, typically consists of 63-67% nickel and 27-33% copper, with small amounts of iron, manganese, and carbon. This composition results in a material that exhibits remarkable resistance to seawater, acids, and alkaline solutions.

Key properties of Monel tubes include:

- Excellent resistance to saltwater and marine environments

- High strength and toughness across a wide temperature range

- Good weldability and formability

- Resistance to stress-corrosion cracking

Understanding these properties is essential when sourcing Monel tubes, as they directly impact the material's performance in various applications.

Industry Standards and Certifications

When searching for reliable Monel tube suppliers, it's crucial to ensure they adhere to recognized industry standards. Some key standards to look for include:

- ASTM B163: Standard Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes

- ASME SB163: Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes

- EN 10095: Heat Resisting Steels and Nickel Alloys

Reputable suppliers should be able to provide material test certificates (MTCs) and other quality assurance documentation. Additionally, look for suppliers with ISO 9001 certification, which demonstrates a commitment to quality management systems.

Dimensional Accuracy and Surface Finish Requirements

The performance of Monel tubes in critical applications often depends on precise dimensional tolerances and surface finish quality. When evaluating suppliers, consider their capabilities in terms of:

- Outside diameter (OD) range: Typically 6.0-114 mm for standard sizes

- Wall thickness (WT) options: Usually ranging from 0.5-15 mm

- Length specifications: Ability to provide tubes up to 15,000 mm in length

- Surface finish: Options for various treatments like sandblasting or anodizing

Ensure that the supplier can meet your specific requirements for dimensional accuracy and surface finish, as these factors can significantly impact the performance and longevity of Monel tubes in your application.

Evaluating Monel Tube Manufacturers' Capabilities and Reliability

Production Facilities and Capacity

When sourcing Monel tubes, it's essential to assess the manufacturing capabilities of potential suppliers. Look for manufacturers with robust production facilities that can meet your demand consistently. Key factors to consider include:

- Number of factories and production lines

- Annual production capacity for Monel alloys

- Advanced machinery and equipment for tube manufacturing

- Ability to handle various tube sizes and specifications

For instance, a supplier with multiple factories, numerous production lines, and a significant annual production capacity is more likely to meet your needs reliably, especially for large or ongoing projects.

Quality Control Measures and Testing Procedures

Reliable Monel tube suppliers implement stringent quality control measures throughout their production process. When evaluating manufacturers, inquire about:

- In-house testing facilities and capabilities

- Non-destructive testing methods (e.g., ultrasonic testing, eddy current testing)

- Hydrostatic pressure testing procedures

- Material composition verification techniques (e.g., X-ray fluorescence spectroscopy)

- Surface quality inspection methods

Look for suppliers who can provide detailed quality control reports and conduct thorough testing to ensure the Monel tubes meet or exceed industry standards. This commitment to quality helps minimize the risk of material failures in critical applications.

Customization and Value-Added Services

Top-tier Monel tube suppliers often offer customization options and additional services to meet specific project requirements. Consider manufacturers who can provide:

- Custom tube sizes and lengths

- Specialized surface treatments or coatings

- Heat treatment services

- Precision cutting and machining

- Assembly or fabrication capabilities

These value-added services can streamline your supply chain and ensure that the Monel tubes you receive are ready for immediate use in your application. Additionally, suppliers offering such services demonstrate a higher level of expertise and commitment to customer satisfaction.

Assessing Supplier Reputation and Customer Support

Industry Experience and Track Record

When sourcing Monel tubes, it's crucial to partner with suppliers who have a proven track record in the industry. Consider the following factors:

- Years of experience in Monel alloy production

- Portfolio of completed projects and applications

- Industry recognition and certifications

- Partnerships with reputable companies or organizations

Suppliers with extensive experience are more likely to understand the nuances of Monel tube production and can provide valuable insights into material selection and application. They're also more likely to have established quality control processes and a stable supply chain.

Customer Reviews and Case Studies

To gauge the reliability and performance of potential Monel tube suppliers, look for:

- Customer testimonials and reviews

- Detailed case studies of successful projects

- Industry references and recommendations

- Performance data and longevity reports from past clients

This information can provide valuable insights into the supplier's ability to meet deadlines, handle complex orders, and provide consistent quality. Pay attention to feedback related to customer service, problem-solving capabilities, and overall satisfaction.

Technical Support and After-Sales Service

Reliable Monel tube suppliers should offer comprehensive support throughout the procurement process and beyond. Evaluate potential partners based on their:

- Technical expertise and willingness to provide material recommendations

- Responsiveness to inquiries and quote requests

- Availability of technical documentation and material data sheets

- Post-sale support and problem resolution capabilities

- Warranty and return policies

Strong customer support can be invaluable, especially when dealing with specialized materials like Monel tubes. A supplier that offers robust technical assistance can help you optimize material selection, troubleshoot issues, and ensure the long-term success of your projects.

Conclusion

Finding reliable Monel tube suppliers requires careful consideration of multiple factors, from material quality and manufacturing capabilities to industry experience and customer support. By thoroughly evaluating potential suppliers based on their adherence to industry standards, production capacity, quality control measures, and reputation, you can identify partners that will consistently deliver high-quality Monel tubes for your critical applications. Remember to request samples, conduct thorough testing, and assess the supplier's ability to meet your specific requirements before making a final decision. With the right supplier, you can ensure a stable supply of superior Monel tubes that will perform reliably in even the most demanding environments.

FAQs

What are the main applications for Monel tubes?

Monel tubes are widely used in marine environments, oil and gas industries, chemical processing, and aerospace applications due to their exceptional corrosion resistance and strength.

How does Monel compare to stainless steel in terms of corrosion resistance?

Monel generally offers superior corrosion resistance compared to stainless steel, especially in seawater and acidic environments. For instance, Monel has a 10x longer lifespan than 316L stainless steel in hydrofluoric acid.

What certifications should I look for when sourcing Monel tubes?

Look for suppliers that provide material test certificates (MTCs), comply with standards like ASTM B163 and ASME SB163, and have ISO 9001 certification for quality management systems.

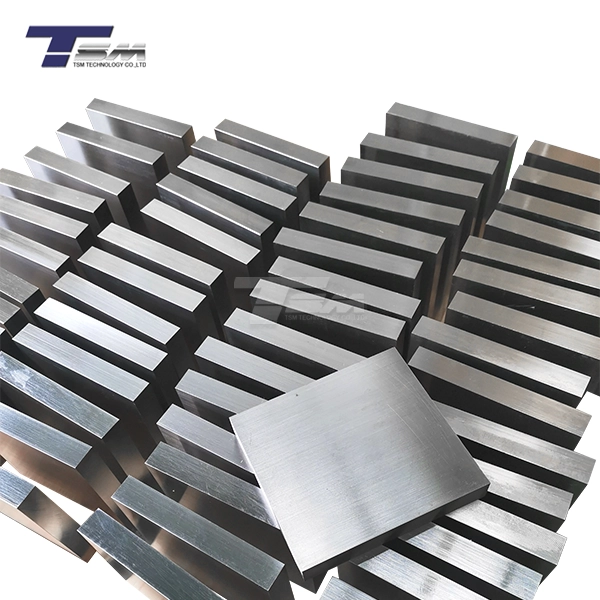

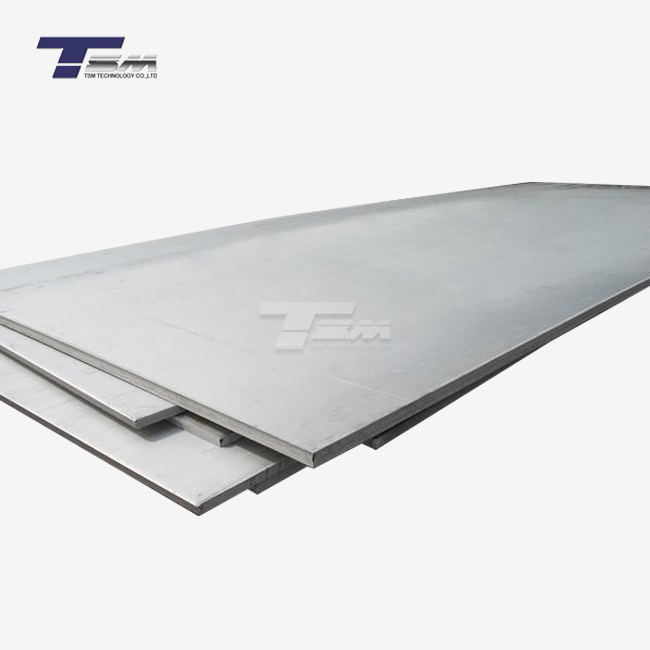

Choose TSM TECHNOLOGY for Premium Monel Tubes

TSM TECHNOLOGY stands out as a premier Monel tube manufacturer and supplier, offering unparalleled quality and service. With our state-of-the-art facilities, rigorous quality control, and extensive experience in nickel alloys, we deliver Monel tubes that meet the most demanding industry standards. Our customization options, comprehensive testing procedures, and commitment to customer satisfaction make us the ideal partner for your Monel tube needs. For more information or to request a quote, please contact us at info@tsmnialloy.com.

References

ASTM International. (2020). "ASTM B163 - Standard Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes."

American Society of Mechanical Engineers. (2019). "ASME SB163 - Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes."

Nickel Institute. (2021). "Nickel-Copper Alloys: Properties and Applications of Monel Alloys."

Journal of Materials Engineering and Performance. (2018). "Corrosion Behavior of Monel 400 in Aggressive Marine Environments."

International Journal of Pressure Vessels and Piping. (2019). "Quality Control and Testing Methods for Nickel Alloy Tubes in Critical Applications."

Materials Science and Engineering: A. (2020). "Mechanical Properties and Microstructure of Monel 400 Tubes for High-Temperature Applications."