- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Heat Treatment is Recommended for Nickel Alloy Bar to Increase Toughness?

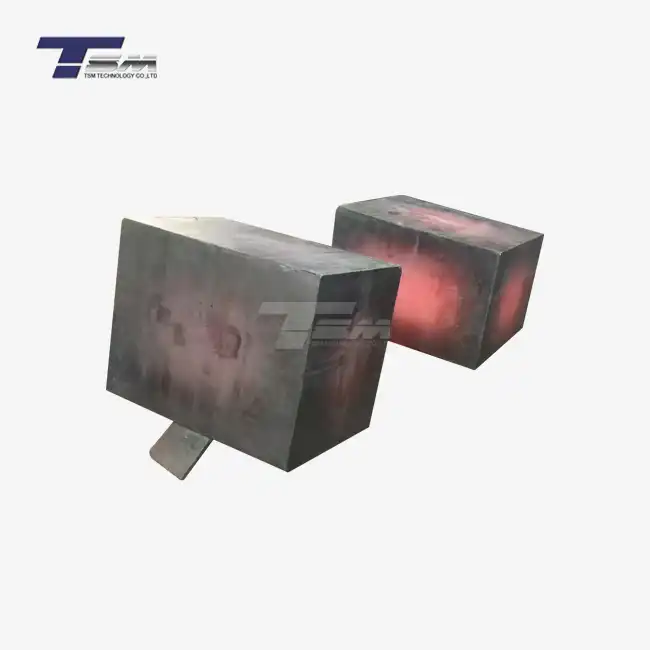

The recommended heat treatment to increase toughness in nickel alloy bars typically involves solution annealing followed by age hardening. For most nickel alloys, solution annealing at temperatures between 980-1200°C (1800-2200°F) dissolves precipitates and homogenizes the microstructure. This is followed by rapid cooling and then age hardening at 600-870°C (1100-1600°F) to form strengthening precipitates. The exact temperatures and times depend on the specific alloy composition. This heat treatment process increases toughness by optimizing the grain structure and precipitate distribution. Proper control of heating rates, soak times, and cooling rates is critical for achieving the desired mechanical properties.

Understanding Nickel Alloy Heat Treatment Processes

Solution Annealing Fundamentals

Solution annealing is a critical first step in heat treating nickel alloy bars to increase toughness. This process involves heating the material to a high temperature, typically between 980-1200°C (1800-2200°F), to dissolve precipitates and create a homogeneous solid solution. The exact temperature depends on the specific alloy composition.

During solution annealing, the nickel alloy bar is held at the elevated temperature for a sufficient time to allow complete dissolution of precipitates and diffusion of alloying elements. This creates a uniform microstructure and chemical composition throughout the material. The soak time can range from 30 minutes to several hours, depending on the alloy and bar thickness.

After the soak period, the material is rapidly cooled or quenched to room temperature. This rapid cooling locks in the homogeneous solid solution structure and prevents the formation of unwanted precipitates. Common quenching methods include water quenching, oil quenching, or air cooling, with the choice depending on the alloy and desired properties.

Age Hardening Process

Following solution annealing, age hardening (also called precipitation hardening) is performed to develop the final strength and toughness properties. This process involves heating the nickel alloy bar to an intermediate temperature, typically between 600-870°C (1100-1600°F), and holding it for a specific time period.

During age hardening, fine precipitates form within the alloy matrix. These precipitates act as obstacles to dislocation movement, thereby strengthening the material. The size, distribution, and volume fraction of these precipitates are carefully controlled through the aging temperature and time to optimize mechanical properties.

For many nickel alloys, a multi-step aging process may be used. This can involve aging at two or more different temperatures to develop an optimal precipitate structure. The exact aging parameters are alloy-specific and tailored to achieve the desired combination of strength and toughness.

Cooling Rate Control

Controlling the cooling rate after both solution annealing and age hardening is crucial for achieving the desired microstructure and properties in nickel alloy bars. Rapid cooling after solution annealing prevents the formation of undesirable phases and maintains the supersaturated solid solution. This is typically achieved through water quenching or forced air cooling.

After age hardening, the cooling rate is often more controlled. Slow cooling in air or furnace cooling may be used to minimize residual stresses and maintain dimensional stability. The specific cooling method is determined based on the alloy composition and the intended application of the nickel alloy bar.

Proper cooling rate control ensures that the strengthening precipitates formed during aging are retained and that the desired balance of strength and toughness is achieved in the final product.

Optimizing Heat Treatment Parameters for Enhanced Toughness

Temperature Selection Considerations

Selecting the optimal temperatures for solution annealing and age hardening is critical for enhancing toughness in nickel alloy bars. The solution annealing temperature must be high enough to dissolve all precipitates but not so high as to cause excessive grain growth or incipient melting. This temperature is typically 50-100°C below the alloy's solidus temperature.

For age hardening, the temperature range is chosen to promote the formation of fine, uniformly distributed strengthening precipitates. Too low a temperature may result in slow precipitation kinetics, while too high a temperature can lead to overaging and loss of strength. Multiple aging steps at different temperatures may be used to achieve an optimal precipitate structure.

Precise temperature control throughout the heat treatment process is essential. Modern heat treatment furnaces with accurate temperature monitoring and control systems are used to maintain the desired temperatures within tight tolerances, typically ±5°C or better.

Time and Duration Factors

The duration of each heat treatment step significantly impacts the final properties of nickel alloy bars. Solution annealing times are typically determined based on the bar diameter and alloy composition. Larger diameter bars require longer soak times to ensure complete homogenization throughout the cross-section.

Age hardening times can vary widely, from a few hours to over 24 hours, depending on the alloy and desired properties. Longer aging times generally promote more complete precipitation and can lead to improved toughness, but excessively long times may result in overaging and property degradation.

In some cases, interrupted aging cycles with intermediate cooling steps may be employed to achieve an optimal balance of strength and toughness. The total heat treatment time, including heating, soaking, and cooling periods, must be carefully managed to ensure process efficiency while achieving the desired material properties.

Atmosphere and Environment Control

Controlling the atmosphere during heat treatment is crucial for preventing surface oxidation and maintaining the desired chemical composition of nickel alloy bars. Vacuum furnaces or protective atmospheres such as argon or nitrogen are commonly used to minimize oxygen exposure during high-temperature treatments.

For some nickel alloys, particularly those containing reactive elements like titanium or aluminum, specialized atmosphere control techniques may be necessary. These can include the use of getter materials or hydrogen-containing atmospheres to prevent the formation of detrimental surface oxides.

Environmental factors such as humidity and ambient temperature in the heat treatment facility must also be controlled to ensure consistent results. Proper maintenance of furnace seals, gas supply systems, and temperature monitoring equipment is essential for maintaining the required atmospheric conditions throughout the heat treatment process.

Impact of Heat Treatment on Nickel Alloy Bar Properties

Microstructural Changes

Heat treatment induces significant microstructural changes in nickel alloy bars, directly influencing their mechanical properties. During solution annealing, the alloy's grain structure is refined, and any pre-existing precipitates are dissolved. This creates a homogeneous solid solution with improved ductility and toughness.

The subsequent age hardening process leads to the formation of fine, coherent precipitates within the alloy matrix. These precipitates, often intermetallic compounds, act as obstacles to dislocation movement. The size, distribution, and volume fraction of these precipitates play a crucial role in determining the alloy's strength and toughness.

Advanced microscopy techniques, such as transmission electron microscopy (TEM) and scanning electron microscopy (SEM), are used to characterize these microstructural changes. Understanding the relationship between heat treatment parameters and resulting microstructures allows metallurgists to fine-tune the process for optimal toughness enhancement.

Mechanical Property Enhancements

Proper heat treatment can significantly enhance the mechanical properties of nickel alloy bars, particularly in terms of strength and toughness. The formation of fine precipitates during age hardening increases the yield strength and ultimate tensile strength of the alloy. This strengthening effect is achieved while maintaining or even improving ductility, resulting in a superior combination of strength and toughness.

Impact toughness, as measured by Charpy V-notch tests, can be substantially improved through optimized heat treatment. The uniform distribution of fine precipitates helps to arrest crack propagation, enhancing the alloy's resistance to brittle fracture.

Fatigue properties are also positively affected by heat treatment. The refined microstructure and improved strength contribute to enhanced fatigue resistance, making heat-treated nickel alloy bars suitable for applications involving cyclic loading.

Corrosion Resistance Effects

Heat treatment can have both positive and negative effects on the corrosion resistance of nickel alloy bars. Solution annealing generally improves corrosion resistance by creating a more homogeneous microstructure and eliminating segregation of alloying elements.

However, the precipitation of certain phases during age hardening can potentially reduce corrosion resistance in some environments. For example, the formation of chromium-rich carbides at grain boundaries can lead to sensitization and increased susceptibility to intergranular corrosion in some nickel-chromium alloys.

To mitigate potential negative effects on corrosion resistance, heat treatment parameters must be carefully controlled. In some cases, a final solution annealing step may be performed after age hardening to restore optimal corrosion resistance while maintaining the desired strength and toughness properties.

Conclusion

Heat treatment is a critical process for enhancing the toughness of nickel alloy bars. The combination of solution annealing and age hardening, when properly executed, results in a microstructure that offers an optimal balance of strength and toughness. By carefully controlling temperatures, times, and cooling rates, manufacturers can tailor the properties of nickel alloy bars to meet specific application requirements.

As the demand for high-performance materials in aerospace, marine, and industrial applications continues to grow, the importance of advanced heat treatment processes cannot be overstated. Ongoing research and development in heat treatment technologies promise to further improve the mechanical properties and performance of nickel alloy bars, opening up new possibilities for their use in extreme environments.

For those seeking nickel alloy bars with superior toughness and reliability, partnering with experienced manufacturers who utilize state-of-the-art heat treatment facilities is essential. By leveraging expert knowledge and precise process control, these manufacturers can deliver nickel alloy bars that meet the most demanding specifications for toughness and overall performance.

FAQs

What is the typical temperature range for solution annealing nickel alloy bars?

Solution annealing is typically performed at temperatures between 980-1200°C (1800-2200°F), depending on the specific alloy composition.

How long does the age hardening process usually take?

Age hardening can take anywhere from a few hours to over 24 hours, depending on the alloy and desired properties.

Can heat treatment improve both strength and toughness simultaneously?

Yes, proper heat treatment can enhance both strength and toughness by optimizing the microstructure and precipitate distribution in nickel alloy bars.

How does heat treatment affect the corrosion resistance of nickel alloy bars?

Heat treatment generally improves corrosion resistance through homogenization, but care must be taken to avoid sensitization in some alloys.

What quality control measures are used to ensure consistent heat treatment results?

Quality control measures include precise temperature monitoring, atmosphere control, and post-treatment mechanical testing to verify property improvements.

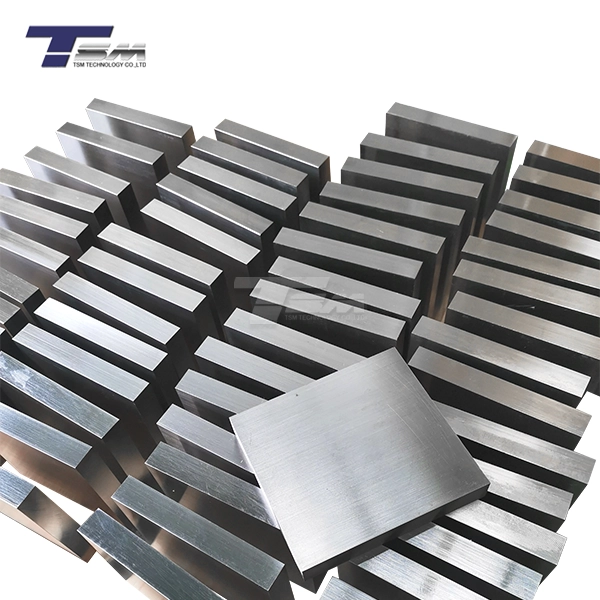

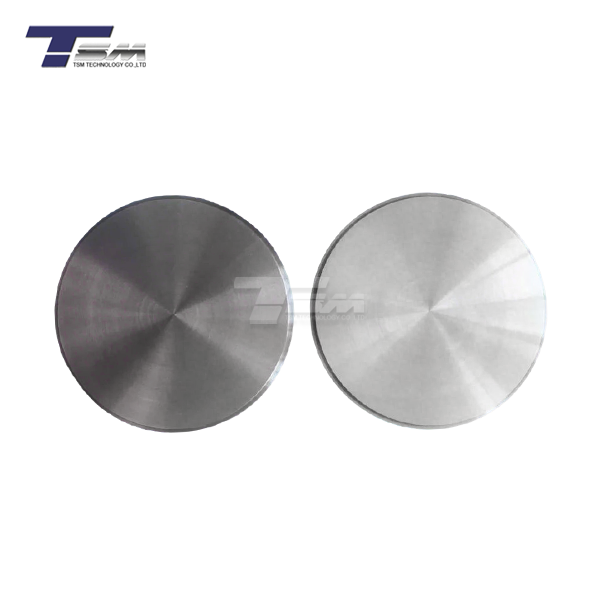

Superior Nickel Alloy Bars with Advanced Heat Treatment | TSM TECHNOLOGY

At TSM Technology, we specialize in producing high-quality nickel alloy bars with optimized heat treatment for enhanced toughness. Our state-of-the-art facility, equipped with advanced heat treatment furnaces and precise control systems, ensures consistent and superior results. With a production capacity of 300 tons per month and a wide range of alloy grades including Inconel, Hastelloy, and Monel, we cater to diverse industrial needs. Our AS9100D certification and rigorous quality control processes guarantee products that meet the most demanding aerospace and industrial standards. For custom nickel alloy bar solutions with exceptional toughness, contact us at info@tsmnialloy.com.

References

Davis, J.R. (Ed.). (2000). Nickel, Cobalt, and Their Alloys. ASM International.

Reed, R.C. (2006). The Superalloys: Fundamentals and Applications. Cambridge University Press.

Donachie, M.J., & Donachie, S.J. (2002). Superalloys: A Technical Guide (2nd ed.). ASM International.

Sims, C.T., Stoloff, N.S., & Hagel, W.C. (Eds.). (1987). Superalloys II: High-Temperature Materials for Aerospace and Industrial Power. John Wiley & Sons.

ASM International. (1991). ASM Handbook, Volume 4: Heat Treating. ASM International.

Geddes, B., Leon, H., & Huang, X. (2010). Superalloys: Alloying and Performance. ASM International.

Learn about our latest products and discounts through SMS or email