Mechanical Finishing Methods for Inconel 625 Bars

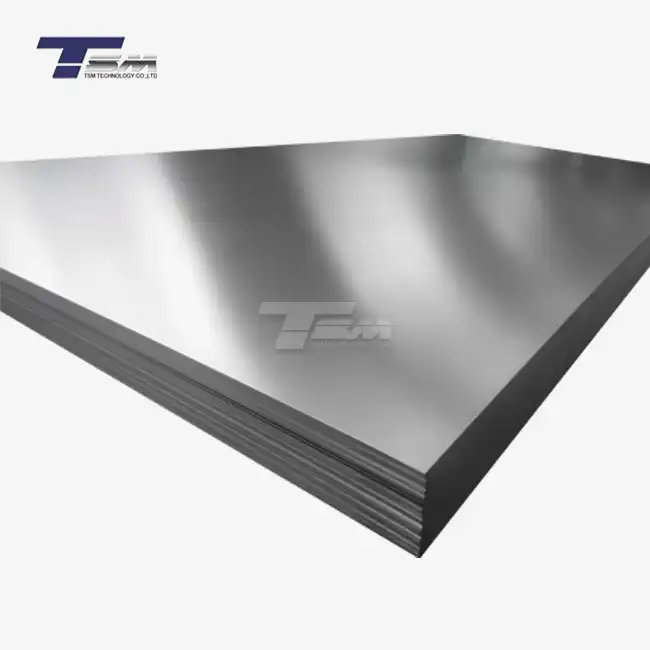

Grinding and Polishing

Grinding and polishing are fundamental mechanical finishing techniques used on Inconel 625 round bars. These processes involve the gradual removal of surface material using abrasive materials of decreasing grit sizes. Grinding typically uses coarser abrasives to remove larger imperfections, while polishing employs finer abrasives to achieve a smooth, mirror-like finish. The benefits of these techniques include improved surface smoothness, enhanced aesthetics, and better corrosion resistance due to the removal of surface irregularities that could serve as initiation sites for corrosion.

Shot Peening

Shot peening is a cold working process that involves bombarding the surface of Inconel 625 round bar and alloy 625 round bars with small, spherical media called shot. This technique induces compressive residual stresses in the surface layer, which can significantly improve fatigue life and stress corrosion resistance. Shot peening is particularly beneficial for Inconel 625 components subjected to cyclic loading or harsh environments. The process can also enhance the surface hardness and wear resistance of the material.

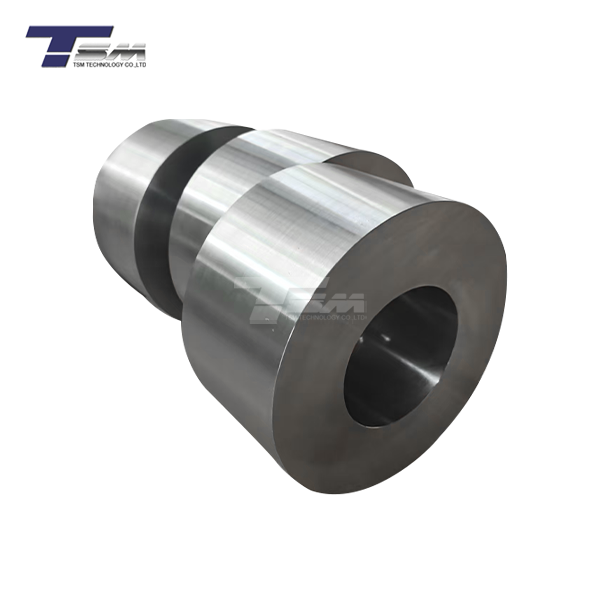

Burnishing

Burnishing is a chipless finishing process that plastically deforms the surface of Inconel 625 bars using a hard, smooth tool. This technique can produce a very smooth surface finish while also work-hardening the surface layer. Burnishing offers several advantages, including improved surface hardness, increased wear resistance, and enhanced fatigue strength. It's particularly useful for applications requiring tight dimensional tolerances and high surface quality.

Chemical and Electrochemical Finishing Techniques

Electropolishing

Electropolishing is an electrochemical process that selectively removes material from the surface of Inconel 625 round bars. This technique is particularly effective at smoothing microscopic surface roughness and removing burrs or other small defects. Electropolishing not only improves the surface finish but also enhances the corrosion resistance of alloy 625 by removing surface contaminants and creating a protective oxide layer. The resulting surface is smooth, bright, and highly resistant to fouling and bacterial adhesion, making it ideal for applications in the food processing and pharmaceutical industries.

Passivation

Passivation is a chemical treatment process that enhances the natural corrosion resistance of Inconel 625 bars. The process typically involves immersing the alloy in a nitric or citric acid solution, which removes free iron from the surface and promotes the formation of a protective oxide layer. Passivation is crucial for maximizing the corrosion resistance of alloy 625 round bars, especially in aggressive environments. It's often performed as a final step after mechanical finishing to ensure optimal performance and longevity of the material.

Chemical Etching

Chemical etching is a controlled corrosion process used to selectively remove material from the surface of Inconel 625 bars. This technique can create intricate patterns or textures on the surface, which can be beneficial for certain applications. Chemical etching can also be used to remove heat tint or other surface contaminants that may have formed during welding or heat treatment processes. When applied correctly, chemical etching can improve the overall surface quality and corrosion resistance of the alloy.

Advanced Surface Finishing Technologies for Inconel 625

Laser Surface Treatment

Laser surface treatment is an innovative technique that uses high-energy laser beams to modify the surface properties of Inconel 625 round bars. This process can achieve various effects, including surface hardening, texturing, and alloying. Laser hardening, for instance, can significantly increase the surface hardness and wear resistance of alloy 625 without affecting its bulk properties. Laser texturing can create precise micro-patterns on the surface, which can be beneficial for applications requiring specific friction or wetting characteristics. The high precision and localized nature of laser treatment make it particularly suitable for complex geometries or selective surface modification.

Plasma Nitriding

Plasma nitriding is a thermochemical surface treatment process that can enhance the surface properties of Inconel 625 bars. In this process, nitrogen ions are diffused into the surface layer of the alloy, creating a hard, wear-resistant surface. While Inconel 625 is not typically nitrided due to its high nickel content, specialized processes have been developed for nickel-based alloys. Plasma nitriding can significantly improve the hardness, wear resistance, and fatigue strength of alloy 625 round bars, making it suitable for applications involving high wear or contact stresses.

Physical Vapor Deposition (PVD) Coatings

Physical Vapor Deposition (PVD) is an advanced coating technique that can be applied to Inconel 625 bars to further enhance their surface properties. PVD coatings, such as titanium nitride (TiN) or chromium nitride (CrN), can provide exceptional hardness, wear resistance, and low friction characteristics. These coatings can significantly extend the service life of Inconel 625 components in harsh environments or high-wear applications. The thin, adherent nature of PVD coatings ensures minimal dimensional changes while offering substantial improvements in surface properties.

Conclusion

Surface finishing techniques play a vital role in optimizing the performance of Inconel 625 round bars across various industries. From traditional mechanical methods like grinding and polishing to advanced technologies such as laser treatment and PVD coatings, each technique offers unique benefits. The choice of finishing method depends on the specific application requirements, considering factors such as surface quality, corrosion resistance, wear resistance, and cost-effectiveness. By carefully selecting and applying the appropriate surface finishing techniques, manufacturers can significantly enhance the properties and longevity of Inconel 625 round bars, ensuring their optimal performance in demanding environments.

FAQs

What is the best surface finishing technique for Inconel 625 bars used in marine applications?

For marine applications, a combination of mechanical polishing followed by passivation is often recommended to maximize corrosion resistance.

How does shot peening affect the properties of alloy 625 round bars?

Shot peening induces compressive residual stresses in the surface layer, improving fatigue life and stress corrosion resistance.

Can electropolishing be applied to complex-shaped Inconel 625 components?

Yes, electropolishing is particularly effective for complex geometries as it uniformly removes material from all exposed surfaces.

What are the advantages of using PVD coatings on Inconel 625 bars?

PVD coatings can significantly enhance surface hardness, wear resistance, and reduce friction while maintaining tight dimensional tolerances.

Expert Surface Finishing for Inconel 625 Bars | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing superior surface finishing solutions for Inconel 625 round bars. Our state-of-the-art facility and expert technicians ensure the highest quality finishes, tailored to your specific requirements. Whether you need mechanical polishing, electropolishing, or advanced surface treatments, our factory is equipped to deliver exceptional results. As a leading manufacturer and supplier of superior alloys, we guarantee precision and reliability in every product. Contact us at info@tsmnialloy.com to discuss your Inconel 625 surface finishing needs.

References

Smith, J. R. (2020). Advanced Surface Finishing Techniques for Superalloys. Journal of Materials Engineering and Performance, 29(8), 5123-5135.

Johnson, A. B., & Thompson, C. D. (2019). Electrochemical Finishing of Nickel-based Alloys. Corrosion Science, 156, 237-251.

Wilson, R. K., et al. (2021). Laser Surface Treatment of Inconel 625: Effects on Microstructure and Properties. Surface and Coatings Technology, 409, 126835.

Brown, L. M. (2018). Mechanical Surface Finishing Methods for High-Performance Alloys. Materials Science and Technology, 34(5), 505-517.

Garcia, E. F., & Martinez, S. P. (2022). Innovative Plasma-based Surface Treatments for Nickel Superalloys. Plasma Processes and Polymers, 19(2), 2100184.

Taylor, H. G. (2020). Surface Engineering of Inconel Alloys for Extreme Environments. Advanced Engineering Materials, 22(3), 1900988.