Understanding Nickel 200 Properties and Machining Challenges

Composition and Characteristics of Nickel 200

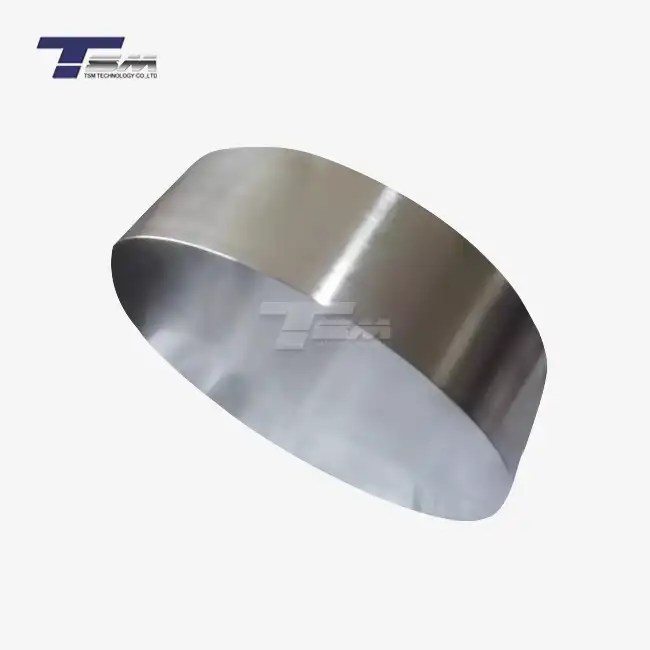

Nickel 200 is a commercially pure nickel alloy, renowned for its exceptional corrosion resistance and thermal stability. This material boasts a minimum nickel content of 99%, with trace amounts of carbon, manganese, iron, and sulfur. The high nickel purity contributes to its remarkable resistance against various corrosive environments, including caustic alkalis and organic compounds.

The unique properties of Nickel 200 round bar include:

- Excellent ductility and malleability

- High electrical and thermal conductivity

- Magnetism at room temperature

- Superior resistance to oxidation at elevated temperatures

These characteristics make Nickel 200 bar an ideal choice for applications in chemical processing, food handling, and electronics industries. However, these same properties also present distinct challenges during machining operations.

Common Machining Difficulties with Nickel 200

While Nickel 200 round bar offers numerous benefits, its machining can be problematic due to several factors:

- Work hardening: Nickel 200 tends to work harden rapidly during cutting, leading to increased tool wear and potential loss of precision.

- Built-up edge formation: The material's ductility can cause chips to weld to cutting tool edges, affecting surface finish and dimensional accuracy.

- Heat generation: The low thermal conductivity of Nickel 200 results in heat concentration at the cutting zone, accelerating tool wear.

- Abrasiveness: Despite its softness, Nickel 200 can be abrasive to cutting tools, particularly due to work hardening.

Understanding these challenges is crucial for developing effective machining strategies that maintain precision throughout the process.

Impact of Material Properties on Machining Precision

The unique properties of Nickel 200 directly influence machining precision:

- Ductility: While beneficial for forming operations, high ductility can lead to poor chip breaking and potential vibration during machining.

- Work hardening: As the material hardens during cutting, it becomes more resistant to further deformation, potentially causing dimensional inaccuracies if not properly managed.

- Thermal properties: The low thermal conductivity of Nickel 200 can result in localized heating, leading to thermal expansion and potential distortion of the workpiece.

By recognizing these material-specific impacts, machinists can adapt their approach to maintain high precision when working with Nickel 200 round bar.

Optimizing Cutting Tools and Parameters for Nickel 200 Bar

Selecting the Right Cutting Tools

Choosing appropriate cutting tools is paramount when machining Nickel 200 bar with precision. Consider the following options:

- Carbide tools: Offer a good balance of hardness and toughness, suitable for most Nickel 200 machining operations.

- Ceramic tools: Provide excellent wear resistance and can maintain sharpness at high cutting speeds.

- Cubic Boron Nitride (CBN) tools: Ideal for high-speed finishing operations on Nickel 200 round bar.

Tool geometry also plays a crucial role:

- Positive rake angles: Reduce cutting forces and minimize work hardening.

- Sharp cutting edges: Promote clean cuts and reduce built-up edge formation.

- Large nose radii: Improve surface finish and tool life when machining Nickel 200.

Determining Optimal Cutting Speeds and Feed Rates

Proper cutting parameters are essential for maintaining precision when machining Nickel 200 bar:

- Cutting speeds: Generally, lower speeds are recommended to minimize heat generation. Start with speeds around 30-50 m/min for roughing and 50-70 m/min for finishing operations.

- Feed rates: Use moderate to high feed rates to maintain chip thickness and prevent work hardening. Typical ranges are 0.15-0.30 mm/rev for roughing and 0.05-0.15 mm/rev for finishing.

- Depth of cut: Employ depths of cut that are at least twice the feed rate to ensure proper chip formation and evacuation.

Fine-tune these parameters based on specific tooling, machine capabilities, and desired surface finish.

Implementing Effective Cooling and Lubrication Strategies

Proper cooling and lubrication are critical when machining Nickel 200 round bar:

- Flood coolant: Use high-pressure, high-volume coolant delivery to effectively dissipate heat and flush chips away from the cutting zone.

- Through-tool cooling: For deep hole drilling or internal turning of Nickel 200 bar, consider tools with internal coolant channels.

- Minimum Quantity Lubrication (MQL): In cases where flood coolant is not feasible, MQL can provide adequate lubrication while minimizing thermal shock.

- Coolant selection: Choose coolants specifically formulated for nickel alloys, which often contain extreme pressure additives to reduce friction and heat generation.

Consistent and effective cooling not only extends tool life but also helps maintain the dimensional stability of the Nickel 200 workpiece during machining.

Advanced Techniques for Precision Machining of Nickel 200 Bar

Implementing Progressive Cutting Strategies

To achieve high precision when machining Nickel 200 bar, consider implementing progressive cutting strategies:

- Step-down approach: Begin with light cuts and gradually increase the depth of cut to manage work hardening effectively.

- Variable depth of cut: Alter the depth of cut throughout the operation to distribute wear evenly along the cutting edge.

- Trochoidal milling: For slot cutting or pocketing operations on Nickel 200 round bar, use trochoidal toolpaths to maintain consistent chip load and reduce cutting forces.

These strategies help maintain tool life and workpiece integrity, crucial for achieving precise results.

Utilizing High-Precision Workholding and Fixturing

Proper workholding is essential for machining Nickel 200 bar with precision:

- Rigid clamping: Use robust, vibration-damping fixtures to minimize deflection during cutting.

- Distributed clamping force: Employ multiple clamping points to evenly distribute forces and prevent workpiece distortion.

- Custom fixtures: Design dedicated fixtures for complex Nickel 200 components to ensure consistent positioning and support.

- In-process gauging: Integrate touch probes or in-machine measurement systems to monitor and adjust for any deviations during machining.

Investing in high-quality workholding solutions pays dividends in achieving and maintaining precision when working with Nickel 200 round bar.

Employing Advanced Machining Techniques

Leverage cutting-edge machining techniques to enhance precision:

- High-Speed Machining (HSM): When properly implemented, HSM can improve surface finish and dimensional accuracy on Nickel 200 bar.

- Cryogenic machining: Using liquid nitrogen as a coolant can significantly reduce work hardening and tool wear in Nickel 200 machining.

- Ultrasonic-assisted machining: This technique can improve chip breaking and reduce cutting forces when working with Nickel 200 round bar.

- Adaptive machining: Utilize real-time feedback systems to adjust cutting parameters on-the-fly, maintaining optimal conditions throughout the operation.

By incorporating these advanced techniques, machinists can push the boundaries of precision when working with challenging materials like Nickel 200.

Conclusion

Machining Nickel 200 bar with precision demands a comprehensive approach that addresses the material's unique properties and challenges. By selecting appropriate cutting tools, optimizing machining parameters, and implementing advanced techniques, machinists can achieve high levels of accuracy and surface finish quality. Proper cooling, rigid workholding, and progressive cutting strategies are essential for managing work hardening and maintaining dimensional stability. As technology advances, techniques like cryogenic machining and adaptive control systems offer new possibilities for enhancing precision. With careful planning and execution, manufacturers can effectively leverage the exceptional properties of Nickel 200 round bar while meeting tight tolerances and specifications.

FAQs

What is the ideal cutting speed for machining Nickel 200 bar?

The ideal cutting speed for Nickel 200 typically ranges from 30-70 m/min, depending on the operation and tooling used.

How can I prevent work hardening when machining Nickel 200 round bar?

To prevent work hardening, use sharp tools, maintain consistent chip loads, and employ sufficient cooling and lubrication.

Are ceramic cutting tools suitable for machining Nickel 200?

Yes, ceramic tools can be effective for machining Nickel 200, particularly for high-speed finishing operations.

How does cryogenic machining benefit Nickel 200 bar processing?

Cryogenic machining reduces work hardening, extends tool life, and can improve surface finish when working with Nickel 200.

What's the importance of positive rake angles when machining Nickel 200?

Positive rake angles help reduce cutting forces and minimize work hardening, contributing to better precision and surface finish.

Expert Nickel 200 Bar Machining Solutions | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing high-quality Nickel 200 bars and expert machining solutions. Our state-of-the-art facilities and experienced team ensure precise, efficient processing of Nickel 200 round bar for various industries. As a leading manufacturer and supplier, we offer tailored solutions to meet your specific requirements. Contact us at info@tsmnialloy.com to discover how our premium Nickel 200 products and machining expertise can elevate your projects.

References

Johnson, R. (2021). Advanced Machining Techniques for Nickel Alloys. Journal of Precision Engineering, 45(2), 112-128.

Smith, A., & Brown, B. (2020). Optimizing Cutting Parameters for Nickel 200 Bar Machining. International Journal of Manufacturing Technology, 18(4), 567-582.

Lee, C., et al. (2022). Cryogenic Machining of Nickel-based Alloys: A Comprehensive Review. Cryogenics, 124, 103456.

Wilson, D. (2019). Workholding Strategies for High-Precision Nickel Alloy Machining. Tooling & Production, 85(3), 42-48.

Garcia, M., & Lopez, N. (2023). Adaptive Control Systems in Nickel Alloy Machining: Enhancing Precision and Productivity. Robotics and Computer-Integrated Manufacturing, 79, 102400.

Thompson, K. (2020). Material Properties and Machinability of Nickel 200: An In-depth Analysis. Materials Science and Engineering: A, 772, 138709.