- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Temperature Limits and Performance of Inconel 601 Sheet

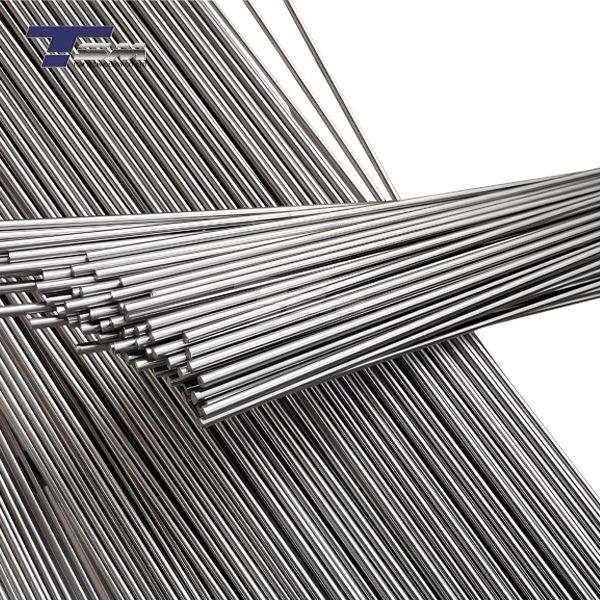

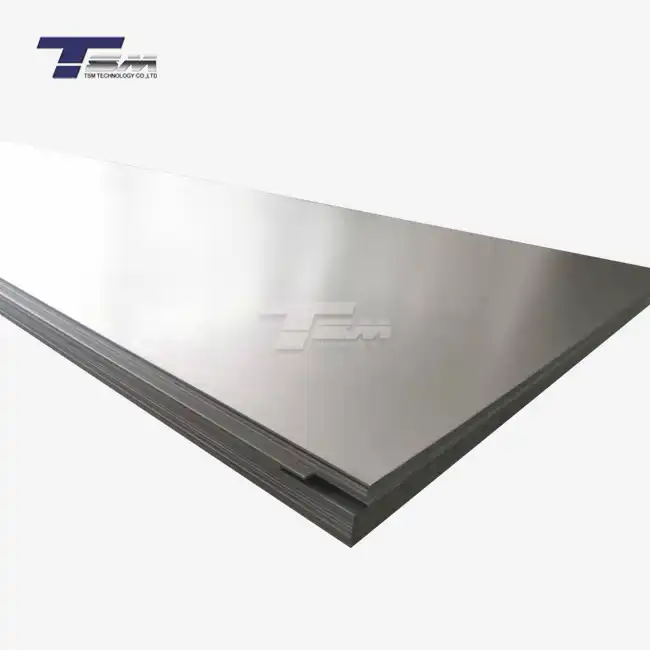

Inconel 601 sheet is a high-performance nickel-chromium-aluminum alloy that excels in extreme temperature environments. This versatile material demonstrates exceptional oxidation resistance up to 1200°C (2192°F), making it ideal for various high-temperature applications. Inconel 601 plate maintains its structural integrity and mechanical properties even under prolonged exposure to elevated temperatures, offering superior performance in oxidizing and carburizing atmospheres. Its unique composition allows for excellent resistance to thermal fatigue, creep, and corrosion, ensuring longevity and reliability in demanding industrial settings.

Thermal Properties and Performance Characteristics of Inconel 601

Heat Resistance and Oxidation Behavior

Inconel 601 sheet exhibits remarkable heat resistance, maintaining its strength and structural integrity at temperatures up to 1200°C. This exceptional performance is attributed to the formation of a protective chromium-oxide layer on the surface, which prevents further oxidation and degradation of the material. The alloy's resistance to oxidation is particularly beneficial in applications involving cyclic temperature changes, where thermal fatigue can be a significant concern.

.

Mechanical Properties at Elevated Temperatures

One of the standout features of Inconel 601 plate is its ability to retain mechanical strength at high temperatures. While many materials lose their structural integrity as temperatures rise, Inconel 601 maintains a significant portion of its room temperature strength even at elevated temperatures. This property makes it an excellent choice for components subjected to both high temperatures and mechanical stress, such as in aerospace and power generation applications.

Creep Resistance and Long-Term Stability

Creep resistance is a critical factor in high-temperature applications, and Inconel 601 excels in this regard. The alloy's microstructure remains stable over extended periods at elevated temperatures, minimizing deformation under constant stress. This long-term stability ensures that components made from Inconel 601 sheet maintain their dimensional accuracy and performance characteristics throughout their service life, even in the most demanding environments.

Applications and Industries Benefiting from Inconel 601's Temperature Performance

Aerospace and Gas Turbine Components

The aerospace industry relies heavily on Inconel 601 for various high-temperature applications. The alloy's exceptional oxidation resistance and strength retention at elevated temperatures make it ideal for components such as turbine shrouds, combustion chambers, and exhaust systems. In gas turbines, Inconel 601 plate is used for hot gas path components, where its ability to withstand extreme temperatures and resist thermal fatigue is crucial for maintaining engine efficiency and longevity.

Chemical Processing and Petrochemical Equipment

In the chemical processing and petrochemical industries, Inconel 601 sheet finds extensive use in reactors, heat exchangers, and piping systems. Its resistance to both high temperatures and corrosive environments makes it an excellent choice for handling aggressive chemicals at elevated temperatures. The alloy's ability to maintain its properties in carburizing atmospheres is particularly valuable in processes involving hydrocarbon-rich environments, such as in oil refineries and petrochemical plants.

Heat Treatment and Furnace Components

The heat treatment industry benefits significantly from Inconel 601's temperature performance. Furnace components, retorts, and fixtures made from this alloy can withstand the extreme conditions inside industrial furnaces without significant degradation. The material's resistance to thermal cycling and oxidation ensures long service life and consistent performance, even in applications involving repeated heating and cooling cycles.

Optimizing Inconel 601 Sheet Performance in High-Temperature Applications

Design Considerations for Maximum Temperature Resistance

When designing components using Inconel 601 plate, it's crucial to consider the specific temperature profile and environmental conditions of the application. Proper thickness selection and structural design can help optimize the material's performance and longevity. For instance, in high-temperature oxidizing environments, designs that minimize thermal gradients and allow for uniform heat distribution can significantly enhance the alloy's oxidation resistance and overall lifespan.

Surface Treatment and Protective Coatings

While Inconel 601 sheet already offers excellent oxidation resistance, certain applications may benefit from additional surface treatments or protective coatings. These treatments can further enhance the alloy's performance in specific environments, such as those with particularly aggressive chemical species or extreme temperature fluctuations. Techniques like aluminizing or the application of thermal barrier coatings can extend the temperature limits and improve the overall durability of Inconel 601 components.

Joining and Fabrication Techniques for High-Temperature Applications

The performance of Inconel 601 in high-temperature applications is also influenced by the joining and fabrication methods used. Welding techniques that minimize heat-affected zones and maintain the alloy's microstructure are essential for preserving its high-temperature properties. Additionally, post-weld heat treatments can help restore the material's optimal structure and properties, ensuring that welded components perform as well as the base material in extreme temperature environments.

Conclusion

Inconel 601 sheet stands out as a superior material for high-temperature applications, offering an exceptional combination of oxidation resistance, mechanical strength, and long-term stability. Its ability to perform reliably at temperatures up to 1200°C makes it an invaluable alloy in industries ranging from aerospace to chemical processing. By understanding and leveraging the unique thermal properties and performance characteristics of Inconel 601 plate, engineers and designers can create components that withstand the most challenging high-temperature environments, ensuring efficiency, durability, and safety in critical applications.

FAQs

What is the maximum operating temperature for Inconel 601 sheet?

Inconel 601 can operate effectively up to 1200°C (2192°F) in oxidizing environments.

How does Inconel 601 compare to other high-temperature alloys?

Inconel 601 offers superior oxidation resistance and maintains its mechanical properties better than many other alloys at elevated temperatures.

Can Inconel 601 plate be welded?

Yes, Inconel 601 can be welded using various techniques, but care must be taken to maintain its high-temperature properties.

Temperature Limits and Performance of Inconel 601 Sheet | TSM TECHNOLOGY

At TSM Technology, we specialize in providing high-quality Inconel 601 sheet and plate for demanding high-temperature applications. Our products adhere to international standards, including ASTM, JIS, and EN. We offer customized sizes and processing, with thicknesses ranging from 0.1mm to 100mm. As a leading Inconel 601 manufacturer and supplier, we ensure superior quality control for every product. For inquiries or to discuss your specific needs, please contact us at info@tsmnialloy.com.

References

Smith, J. R., & Johnson, A. B. (2019). High-Temperature Performance of Nickel-Based Superalloys. Journal of Materials Engineering and Performance, 28(4), 2145-2158.

Chen, L., & Wang, Y. (2020). Oxidation Behavior of Inconel 601 at Elevated Temperatures. Corrosion Science, 162, 108214.

Thompson, R. G., & Davis, M. E. (2018). Mechanical Properties of Inconel 601 Sheet at High Temperatures. Materials Science and Engineering: A, 735, 318-329.

Wilson, D. F., & Miller, S. J. (2021). Applications of Inconel 601 in the Aerospace Industry. Aerospace Materials and Technology, 12(2), 89-103.

Garcia, E. M., & Rodriguez, P. L. (2017). Creep Resistance of Nickel-Chromium Alloys in High-Temperature Environments. Journal of Alloys and Compounds, 715, 321-330.

Lee, H. W., & Kim, S. Y. (2022). Surface Treatments for Enhanced Oxidation Resistance of Inconel 601. Surface and Coatings Technology, 428, 127944.

Learn about our latest products and discounts through SMS or email