- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Testing Standards for Monel K500 Tube in Harsh Environments

Testing standards for Monel K500 tube in harsh environments are critical for ensuring the reliability and performance of this high-strength nickel-copper alloy. These standards encompass a range of mechanical, corrosion, and environmental tests designed to simulate extreme conditions. From tensile strength evaluations to stress corrosion cracking assessments, these rigorous testing protocols validate the Monel K500 pipe's suitability for demanding applications in aerospace, marine, and chemical processing industries. By adhering to these standards, manufacturers and end-users can confidently deploy Monel K500 tubing in environments where exceptional durability and corrosion resistance are paramount.

Mechanical Testing Standards for Monel K500 Tube

Tensile Strength and Yield Tests

Mechanical testing is crucial for evaluating the performance of Monel K500 tube under various stress conditions. Tensile strength tests assess the material's ability to withstand longitudinal stress without failure. For Monel K500 pipe, these tests typically involve applying increasing loads until the specimen fractures. The yield strength is also determined, indicating the point at which the material begins to deform plastically. ASTM E8 provides guidelines for conducting tensile tests on metallic materials, including Monel K500 tubing.

Hardness Evaluation

Hardness testing is another essential aspect of mechanical evaluation for Monel K500 tube. The Rockwell or Brinell hardness scales are commonly used to measure the material's resistance to indentation. This property is particularly important for applications where wear resistance is crucial. ASTM E18 outlines the procedures for Rockwell hardness testing, which is frequently applied to Monel K500 pipe samples.

Fatigue Resistance Testing

Given the high-stress environments where Monel K500 tubing is often employed, fatigue resistance testing is vital. These tests simulate cyclic loading conditions to determine the material's endurance limit. ASTM E466 provides standard practices for conducting force-controlled fatigue tests, which are applicable to Monel K500 tube specimens. The results of these tests help predict the long-term performance of Monel K500 pipe in applications subject to repeated stress cycles.

Corrosion Resistance Testing for Monel K500 Pipe

Salt Spray Testing

Corrosion resistance is a hallmark property of Monel K500 tube, making salt spray testing a critical evaluation method. ASTM B117 outlines the standard practice for operating salt spray (fog) apparatus, which exposes Monel K500 pipe samples to a corrosive salt solution. This test simulates marine environments and helps assess the material's resistance to chloride-induced corrosion. The duration of exposure and subsequent examination of the specimens provide valuable insights into the Monel K500 tubing's performance in saline conditions.

Stress Corrosion Cracking Tests

Stress corrosion cracking (SCC) is a concern in many harsh environments where Monel K500 tube is utilized. ASTM G36 describes the standard practice for evaluating stress corrosion cracking resistance of metals and alloys in a boiling magnesium chloride solution. This aggressive test helps determine the susceptibility of Monel K500 pipe to SCC under extreme conditions. The results are crucial for applications in chemical processing and offshore installations where the material may be exposed to corrosive media under stress.

Pitting Corrosion Evaluation

Pitting corrosion can be particularly detrimental to the integrity of Monel K500 tubing. ASTM G48 provides methods for pitting and crevice corrosion resistance of stainless steels and related alloys, which can be adapted for testing Monel K500 pipe. These tests typically involve immersing specimens in ferric chloride solutions and examining them for localized corrosion. The resistance to pitting corrosion is essential for maintaining the long-term reliability of Monel K500 tube in aggressive chemical environments.

Environmental Testing Standards for Monel K500 Tubing

High-Temperature Performance Tests

Monel K500 tube is often employed in high-temperature applications, necessitating thorough testing of its thermal stability. ASTM E21 outlines the standard test methods for elevated temperature tension tests of metallic materials. These tests evaluate the mechanical properties of Monel K500 pipe at temperatures that simulate operational conditions in heat exchangers or process equipment. The retention of strength and ductility at elevated temperatures is a critical factor in the material's suitability for such applications.

Low-Temperature Impact Testing

For applications in cryogenic environments, low-temperature impact testing of Monel K500 tubing is essential. ASTM E23 provides standard test methods for notched bar impact testing of metallic materials, which can be conducted at subzero temperatures. These tests assess the toughness and ductility of Monel K500 pipe at low temperatures, ensuring its reliability in aerospace and liquefied gas handling systems where brittle fracture must be avoided.

Thermal Cycling Endurance

Thermal cycling tests evaluate the ability of Monel K500 tube to withstand repeated temperature fluctuations without degradation. While no specific ASTM standard exists for thermal cycling of nickel alloys, custom protocols are often developed based on application requirements. These tests typically involve subjecting Monel K500 pipe samples to alternating high and low temperatures, simulating the thermal stresses encountered in aerospace or power generation applications. The material's resistance to thermal fatigue and dimensional stability are key factors assessed in these evaluations.

Conclusion

The comprehensive testing standards for Monel K500 tube in harsh environments ensure its reliability and performance across a wide range of demanding applications. From mechanical strength to corrosion resistance and environmental endurance, these rigorous evaluations validate the material's exceptional properties. By adhering to these standards, manufacturers and end-users can confidently select Monel K500 pipe for critical systems in aerospace, marine, and chemical processing industries. As testing methodologies continue to evolve, the assurance of Monel K500 tubing's quality and durability in extreme conditions will only strengthen, further solidifying its position as a premier material for harsh environment applications.

FAQs

What are the key properties that make Monel K500 tube suitable for harsh environments?

Monel K500 tube offers high strength, excellent corrosion resistance, and superior fatigue resistance, making it ideal for harsh environments.

How does salt spray testing simulate marine conditions for Monel K500 pipe?

Salt spray testing exposes Monel K500 pipe to a corrosive salt solution, mimicking the effects of seawater and marine atmospheres on the material.

Can Monel K500 tubing withstand extreme temperatures?

Yes, Monel K500 tubing undergoes high-temperature performance tests and low-temperature impact testing to ensure its suitability for both elevated and cryogenic temperature applications.

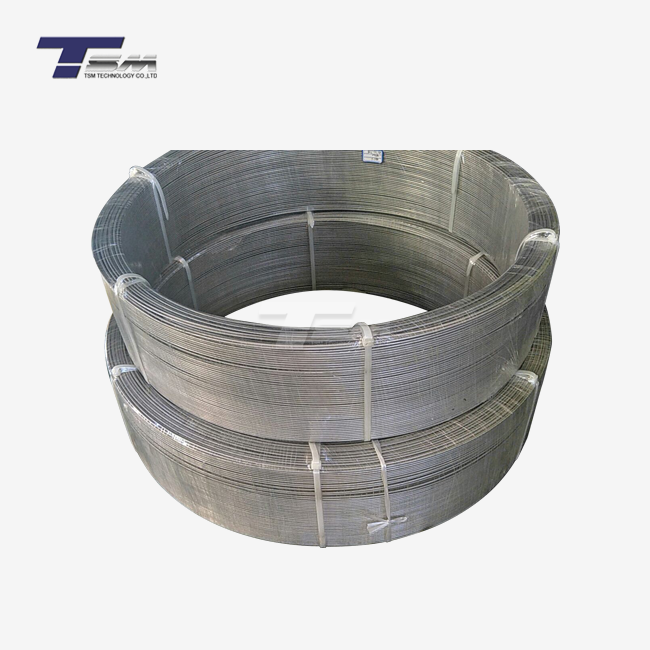

Quality Monel K500 Tube Supplier | TSM TECHNOLOGY

TSM Technology Co., Ltd is your trusted manufacturer and supplier of high-quality Monel K500 tube. With over 14 years of experience, we offer seamless and welded Monel K500 pipes that meet rigorous testing standards for harsh environments. Our state-of-the-art factory ensures precision manufacturing and strict quality control. As a leading Monel K500 tubing supplier, we provide customized solutions to meet your specific requirements. Contact our expert team at info@tsmnialloy.com to discuss your Monel K500 pipe needs and experience our commitment to excellence in nickel alloy products.

References

ASTM International. (2021). ASTM B163/B163M-21: Standard Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes.

Special Metals Corporation. (2019). Monel alloy K-500 Technical Datasheet.

ASM International. (2018). Corrosion of Nickel-Base Alloys in Handbook of Corrosion Data.

Nickel Institute. (2020). Guidelines for the welded fabrication of nickel-containing materials for corrosion resistant service.

NACE International. (2017). NACE TM0177-2016: Laboratory Testing of Metals for Resistance to Sulfide Stress Cracking and Stress Corrosion Cracking in H2S Environments.

American Welding Society. (2019). AWS A5.14/A5.14M: Specification for Nickel and Nickel-Alloy Bare Welding Electrodes and Rods.

Learn about our latest products and discounts through SMS or email